When it comes to keeping hydraulic and pneumatic systems running smoothly, understanding the difference between piston ring sealer, hydraulic rod seals, and a rod gland seal is essential. These sealing components may look similar but play very distinct roles inside cylinders. Knowing their functions, materials, and application differences can help improve efficiency, reduce maintenance, and extend equipment life.

In this comprehensive guide, we’ll explore the working principles behind piston and rod seals, where they’re used, and what sets them apart—so you can choose the right solution for your hydraulic system. Know more..

What Are Piston Seals?

Piston seals are used on the moving piston inside a hydraulic or pneumatic cylinder. Their job is to seal the pressure on one side of the piston, preventing fluid or air from leaking past to the other side. In essence, piston ring sealer components ensure that the pressure generated within the cylinder creates force in the intended direction.

Piston seals are installed into grooves on the piston head and move with it along the cylinder bore. When they fail, pressure leaks between the two chambers, causing a drop in system performance.

Key functions of piston seals include:

- Maintaining pressure differentials between cylinder chambers

- Enabling accurate piston positioning

- Minimizing friction and wear on cylinder surfaces

What Are Rod Seals?

Hydraulic rod seals, often referred to as rod gland seals, are mounted in the gland (or head) of the cylinder and provide a seal around the piston rod as it exits the cylinder.

Their primary role is to contain the system fluid within the cylinder while preventing external contaminants—like dust, dirt, and moisture—from entering.

Unlike piston ring sealer elements, rod seals deal with both internal pressure and external exposure, making their sealing performance critical to system life and safety.

Core functions of rod seals include:

- Preventing leakage of hydraulic fluid along the rod

- Keeping dirt and contaminants out of the cylinder

- Supporting wiper and buffer seals in extreme conditions

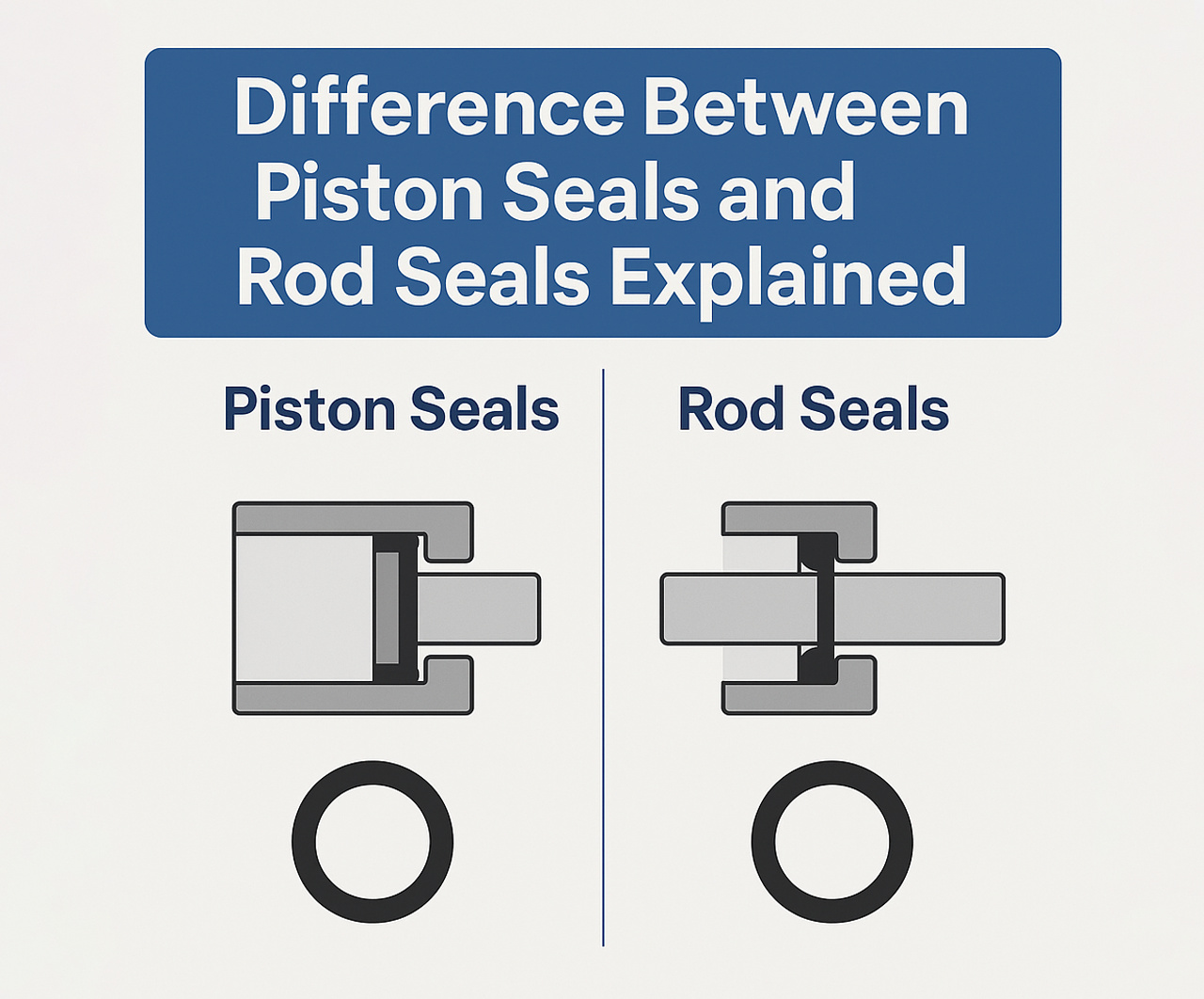

Where Each Seal Is Located

To understand their importance, it helps to visualize where these seals are in a hydraulic cylinder:

- Piston seals sit in grooves around the piston itself, inside the bore.

- Hydraulic rod seals are installed in the gland section where the rod extends out of the cylinder.

- Rod gland seal is sometimes used as a general term for the combination of seals located in the gland, including the main rod seal, buffer seal, and wiper seal.

Design and Material Differences

Because piston ring sealer and rod gland seal functions are different, their designs and materials are optimized accordingly.

Piston seals are designed to withstand pressure differentials across the piston. Materials must balance flexibility with compressive strength. Common materials include:

- Polyurethane (PU)

- PTFE (Teflon) with elastomer energizers

- Nitrile rubber (NBR)

- FKM (Viton) for high-temperature applications

Hydraulic rod seals require additional abrasion resistance due to rod movement and contamination. They are often supported by:

- Wipers (scrapers)

- Buffer seals (shock absorbers)

Rod seal materials often include:

- NBR with PTFE inserts

- High-density polyurethane

- Thermoplastic elastomers for low-friction, high-durability sealing

Seal Types and Profiles

Let’s break down some common styles for each seal type:

Piston Seal Types:

- Single-acting piston seals: Seal in one direction

- Double-acting piston seals: Seal pressure from both directions (used in double-acting cylinders)

- Chevron seals: Stacked V-ring sets that flex under pressure

Rod Seal Types:

- U-cup seals: A common profile offering high sealing with low friction

- Lip seals: Provide tight contact with the rod and resist extrusion

- Buffer seals: Used ahead of rod seals to absorb pressure spikes

While both seal types can come in similar profiles, their geometry is fine-tuned to handle directional pressure, movement, and environmental exposure differently.

Failure Modes: What Goes Wrong

Understanding how piston ring sealer and hydraulic rod seals fail helps in diagnostics and maintenance planning.

Piston Seal Failures:

- Pressure loss between chambers

- Internal leakage

- Wear from side-loading or misalignment

- Material degradation from fluid incompatibility

Rod Seal Failures:

- External leakage

- Ingress of contaminants

- Extrusion from high pressure without a buffer seal

- Thermal cracking or hardening due to temperature spikes

In both cases, failures can lead to loss of efficiency, higher energy usage, and system downtime.

Maintenance Tips for Both Seal Types

To prolong the life of both piston ring sealer and rod gland seal components:

- Regularly inspect for leaks and performance drops

- Check for rod straightness and piston alignment

- Use fluid that matches the seal material’s chemical compatibility

- Replace worn wipers to reduce contamination

- Avoid high-speed operation with inadequate lubrication

Routine maintenance can double the lifespan of hydraulic rod seals and improve system reliability.

Application Examples

Piston Seals:

- Industrial presses

- Automotive braking systems

- Mobile hydraulics (excavators, loaders)

- Pneumatic actuators

Rod Seals:

- Telescopic cylinders

- Injection molding machines

- Agricultural machinery

- High-pressure lifting systems

In high-duty applications like forklifts and cranes, both piston ring sealer and rod gland seal components work together to create robust, efficient systems.

Emerging Trends in Seal Technology

As sealing needs evolve, manufacturers are innovating with:

- Low-friction coatings to reduce wear and improve energy efficiency

- Smart seals with embedded sensors for predictive maintenance

- Hybrid seals that combine piston and rod sealing in compact units

- Green materials that offer biodegradability or recyclability

These advances mean better performance, less downtime, and eco-friendlier sealing solutions.

Choosing the Right Seal

When selecting between piston ring sealer, hydraulic rod seals, and a rod gland seal, consider:

- Operating pressure and direction

- Cylinder type (single or double-acting)

- Fluid compatibility

- Speed and frequency of operation

- External environmental exposure

Working with a trusted seal manufacturer or distributor ensures you get the right material, profile, and dimensions for your application.

Conclusion

While they might operate in the same hydraulic system, piston ring sealer and hydraulic rod seals serve very different purposes. One controls internal pressure between chambers, while the other keeps that pressure contained within the system and blocks outside contamination.

Both are critical to system performance, efficiency, and longevity. Understanding the function and design of each—along with their role in the broader rod gland seal setup—can prevent failure, reduce maintenance, and increase productivity.