In the world of industrial sealing solutions, few names command as much respect as CFW seals, CFW oil seal, and Simrit oil seal. With reliability, durability, and high-performance engineering at the heart of both brands, the decision between them often comes down to specific applications and operating environments. Whether you’re sourcing components for heavy-duty machinery or high-pressure hydraulic systems, comparing Simrit hydraulic seals and CFW options is essential to making a smart long-term investment.

This article offers an in-depth, creative comparison of these premium oil seal manufacturers, highlighting their strengths, differences, and ideal use cases. If you’re a design engineer, maintenance manager, or procurement specialist, this guide will help you make an informed decision. Know more..

The Legacy Behind the Brands

CFW seals come from a brand rooted in German engineering. A part of the Freudenberg Sealing Technologies family, CFW specializes in sealing solutions for automotive, industrial, and agricultural applications. The brand is known for its comprehensive catalog, which includes CFW oil seal products built to handle a variety of chemical, thermal, and pressure conditions.

On the other side, Simrit oil seal is a well-established brand also under the Freudenberg umbrella. Simrit offers premium sealing technology for highly demanding sectors such as aerospace, wind energy, and medical devices. Simrit hydraulic seals are particularly favored for their precision, longevity, and low-friction design in fluid power systems.

Though both are connected to Freudenberg, their product philosophies and market focus often diverge—and that’s where the decision-making begins.

Material Innovation and Compatibility

CFW seals are known for their robust use of elastomeric compounds, including NBR (nitrile rubber), FKM (fluoroelastomer), and PTFE (Teflon-based materials). These materials allow CFW oil seal designs to perform under varying chemical exposures, such as fuels, lubricants, and hydraulic oils.

Simrit hydraulic seals, in contrast, focus heavily on high-performance polymer blends like AU (polyurethane) and EPDM. These compounds offer excellent resistance to wear and extreme temperature fluctuations. In fact, Simrit oil seal units have a reputation for maintaining tight sealing performance even in sub-zero conditions or continuous high-speed operations.

So, when temperature range and chemical compatibility are critical, Simrit oil seal products may offer an edge. For general industrial applications with medium pressure and thermal conditions, CFW seals are often more cost-effective without sacrificing performance.

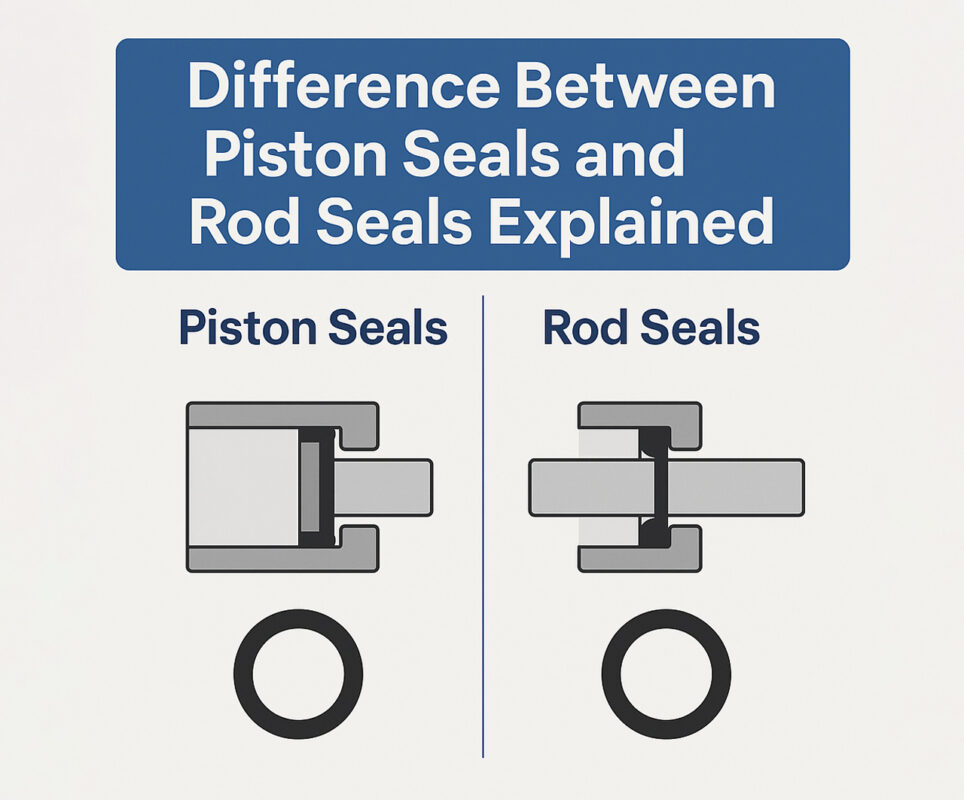

Engineering and Design Differences

CFW prioritizes standardization and global interchangeability. Their CFW oil seal catalog includes ISO and DIN-compliant profiles that are drop-in replacements for OEM parts. These seals are designed for broad compatibility across various machine types.

Simrit hydraulic seals, on the other hand, feature custom-engineered geometries. For example, their asymmetric lip designs, spiral grooves, and reduced-friction surfaces ensure longer service life in hydraulic and pneumatic systems. Simrit oil seal configurations often include dual-lip and multi-material constructions that minimize leakage even in misaligned or pulsating systems.

This means Simrit hydraulic seals shine in high-precision environments like robotics, aerospace, and energy, while CFW seals provide reliable performance in heavy machinery, agriculture, and automotive applications.

Pressure and Speed Ratings

When choosing between CFW seals and Simrit oil seal products, understanding operating pressure and shaft speed is essential.

- CFW oil seal units typically support medium-pressure systems up to 10 bar and shaft speeds up to 10,000 RPM, depending on the compound.

- Simrit hydraulic seals can exceed these specs, often handling pressures up to 40 bar and higher speeds when combined with lubrication management systems.

For high-speed rotary shafts or oscillating systems under pressure, Simrit hydraulic seals are the clear choice. But for less extreme applications with intermittent duty cycles, CFW seals hold their own.

Product Range and Application Coverage

Both brands offer an expansive portfolio:

- CFW seals provide options like rotary shaft seals, valve stem seals, and transmission gaskets. Their CFW oil seal lineup includes dust lips, spring-loaded designs, and PTFE-coated variants.

- Simrit oil seal offerings include O-rings, wipers, bonded seals, and advanced hydraulic kits. Simrit hydraulic seals cater specifically to actuators, control valves, and servo systems.

If your focus is wide-ranging industrial machinery, CFW seals may give you more standard options at better pricing. But if your application demands high-purity, ultra-reliable sealing—such as in pharmaceuticals or clean rooms—Simrit oil seal components are hard to beat.

Durability and Service Life

Thanks to premium materials and engineering, both brands offer exceptional durability. However, Simrit hydraulic seals are designed for extended cycles without maintenance. In field tests, they have shown to outperform other brands by up to 40% in terms of wear resistance and compression set.

CFW oil seal units also offer impressive life, especially when paired with compatible lubricants. For moderate-duty systems with predictable maintenance schedules, they deliver excellent value.

Still, if your goal is to minimize intervention in mission-critical applications, Simrit oil seal solutions provide greater peace of mind.

Availability and Global Support

CFW seals enjoy widespread distribution through OEM channels and aftermarket suppliers across Europe, Asia, and Latin America. Their standardized parts are usually readily available off-the-shelf.

Simrit oil seal and Simrit hydraulic seals, due to their custom nature, may require lead time. However, they come with superior technical support, especially in regulated industries.

If rapid replacement and inventory stocking are your priorities, CFW oil seal may be easier to manage. But for design-first strategies, the engineering support behind Simrit hydraulic seals adds real value.

Cost Comparison

Let’s talk money. CFW seals are often priced more competitively due to their standardized design and mass production.

Simrit oil seal products cost more upfront but can reduce total cost of ownership through:

- Reduced downtime

- Fewer replacements

- Better energy efficiency via tight sealing

When cost-per-unit matters most, CFW oil seal is a budget-friendly solution. But when system reliability is mission-critical, Simrit hydraulic seals are a strategic investment.

Sustainability and Innovation

Freudenberg has made strong sustainability commitments across both brands. However, Simrit oil seal products increasingly incorporate low-friction coatings, recyclable materials, and clean manufacturing processes.

CFW seals, meanwhile, are often developed with modular tooling and reduced waste, making them ideal for manufacturers focusing on cost-effective sustainability.

In R&D terms, Simrit hydraulic seals are leading innovations in sealing for hydrogen fuel cells, electric mobility, and smart actuators.

Industry Use Case Examples

- Automotive: CFW shaft seals in gearboxes and wheel hubs offer reliable sealing for daily drivers.

- Aerospace: Simrit radial seals in pressurized cabins and landing gear ensure safety and compliance.

- Medical: Simrit micro seals in pumps and infusion systems meet biocompatibility standards.

- Agricultural: CFW seals in tractor hydraulics provide long life in muddy, dusty fields.

Final Verdict: Which Should You Choose?

Choose CFW seals if you need:

- Budget-conscious solutions

- Quick access and global supply

- Standardized sizing and profiles

- Reliable performance in general industrial machinery

Choose Simrit oil seal or Simrit hydraulic seals if you need:

- Precision sealing under extreme conditions

- Support for customized designs

- Longer maintenance intervals

- Specialized applications in aerospace, medical, or high-speed hydraulics

Both brands bring decades of engineering excellence to the table. Your choice should align with your application’s complexity, performance requirements, and total cost strategy.

No matter which you pick, you’re choosing from the top tier of oil seal technology. Understanding the differences empowers you to get the most from every rotation, every pressure pulse, and every drop of hydraulic fluid.