In industrial sealing, few components are as universally relied upon as the o ring. From simple fluid connections to complex hydraulic and pneumatic systems, the o ring o ring is the go-to sealing solution for engineers and procurement teams alike. Whether you’re sourcing standard rubber o rings for general equipment maintenance or specialized compounds for harsh environments, understanding how o-rings function, fail, and vary in materials is key to making a smart purchase.

This complete guide is designed for industrial buyers who want more than just part numbers. We’ll dive into what an o ring is, where it’s used, how to choose the right one, and why quality matters. Know more..

What Is an O-Ring?

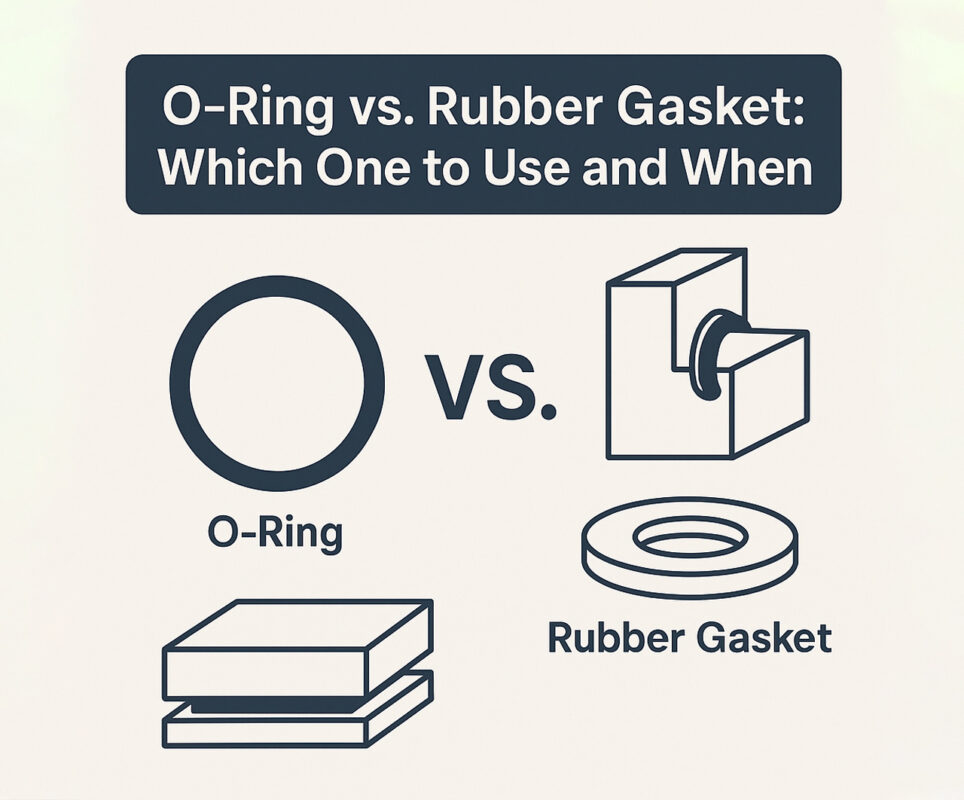

An o ring is a torus-shaped (donut-shaped) gasket used to prevent the passage of liquids or gases. It sits in a groove and compresses between two surfaces to create a seal.

The simplicity of the o ring o ring design belies its versatility. With no moving parts, o-rings provide reliable static and dynamic sealing under pressure, vacuum, and temperature extremes.

Common Uses for O-Rings

Rubber o rings are found in nearly every industrial sector:

- Hydraulics: Prevent fluid leakage in pumps, valves, and cylinders.

- Pneumatics: Maintain pressure and eliminate air leaks in actuators and fittings.

- Automotive: Seal fuel systems, air conditioners, and brake lines.

- Food processing: Ensure sanitary seals in washdown-resistant equipment.

- Aerospace: Provide pressure integrity in aircraft engines and environmental systems.

With so many applications, there’s no such thing as a one-size-fits-all o ring.

Materials: Why Rubber O Rings Are Popular

The choice of material determines how an o ring performs under load, temperature, chemical exposure, and movement.

Rubber o rings dominate because they offer flexibility, cost-effectiveness, and resistance to various conditions. Key rubber materials include:

- Nitrile (NBR): Great for oil, fuel, and water resistance. Ideal for industrial maintenance.

- EPDM: Excellent for steam, water, and UV exposure. Common in plumbing and outdoor systems.

- Viton (FKM): Resistant to heat and chemicals. Often used in automotive and aerospace.

- Silicone: Food-grade and flexible at extreme temperatures. Used in medical and food industries.

- Neoprene: Good for refrigeration and outdoor environments.

Buyers must match rubber o rings to operating conditions, or risk degradation, swelling, or cracking.

How O-Rings Work

When compressed in a groove, the o ring deforms to fill the space and create a seal. The elasticity of the material allows it to return to shape when pressure is removed, maintaining a tight barrier.

There are two main types of sealing:

- Static: No relative motion between surfaces (e.g., pipe flange)

- Dynamic: Surfaces move (e.g., piston sliding in a cylinder)

The o ring o ring system must balance groove dimensions, compression rate, and material hardness (durometer) to work effectively.

Choosing the Right O-Ring for Your Application

Selecting the best o ring starts with answering a few key questions:

- What media will it seal?

- Oils, chemicals, gases, steam, water?

- What is the temperature range?

- Cold storage? High-heat engines?

- Is the seal static or dynamic?

- What is the required pressure tolerance?

- Vacuum or high-pressure hydraulics?

- Does it need food or medical-grade compliance?

For example, rubber o rings made from EPDM will fail quickly in petroleum environments, but thrive in steam systems.

O-Ring Sizes: Global Standards

Standard sizes are governed by organizations like:

- AS568 (USA)

- ISO 3601 (International)

- BS 1806 (UK)

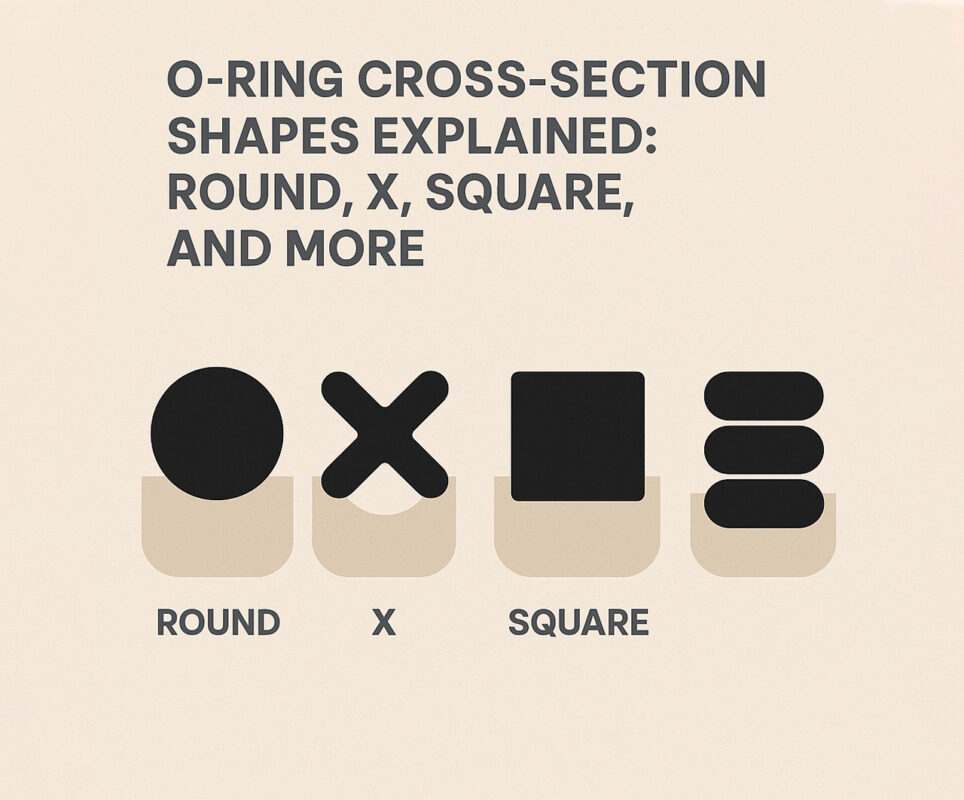

When specifying an o ring, buyers must know:

- Inside diameter (ID)

- Cross-section (CS)

Custom and non-standard rubber o rings can be fabricated, but often involve longer lead times and higher costs.

Common O-Ring Failures (and How to Avoid Them)

Knowing why o ring failures happen helps prevent costly downtime.

- Compression Set: O-ring doesn’t return to shape after compression.

- Cause: Heat, chemical attack, poor material choice.

- Extrusion: Material is forced into the gap between mating surfaces.

- Cause: Excessive pressure or incorrect groove dimensions.

- Abrasion: Surface wear due to motion or contamination.

- Cause: Poor finish on metal surfaces, insufficient lubrication.

- Chemical Degradation: Swelling, cracking, or softness.

- Cause: Exposure to incompatible media.

- Installation Damage: Nicked or twisted seals during assembly.

- Cause: Sharp edges, improper tools.

The better matched your rubber o rings are to your environment, the less frequently you’ll encounter failure.

Storage and Handling Tips

Even before installation, o ring o ring quality can degrade if not stored properly. Follow these best practices:

- Store in a cool, dry place away from direct sunlight.

- Keep away from ozone sources (motors, fluorescent lighting).

- Avoid stretching or compressing during storage.

- Label materials and expiration dates clearly.

Proper handling extends shelf life and ensures top sealing performance.

Specialized O-Rings for Industrial Applications

Sometimes, standard rubber o rings won’t cut it. In these cases, specialty o-rings are used:

- Backup rings: Prevent extrusion in high-pressure applications.

- Quad rings (X-rings): Provide better sealing in dynamic environments.

- Metal-detectable o-rings: Used in food and pharma to prevent contamination.

- PTFE encapsulated o-rings: Combine chemical resistance with rubber elasticity.

- Color-coded o-rings: For easy identification in complex systems.

These innovations solve sealing challenges in demanding applications.

Buying Considerations: What Industrial Buyers Need to Know

When sourcing o ring o ring components in bulk, industrial buyers should prioritize:

- Supplier reliability: Are delivery times consistent? Is inventory managed well?

- Material certification: Does the supplier offer FDA, NSF, or MIL-SPEC options?

- Technical support: Can they recommend alternatives or troubleshoot?

- MOQ and lead times: How fast can you get critical rubber o rings?

- Customization: Can they provide specific durometer or compound blends?

Establishing a relationship with a knowledgeable supplier pays dividends over time.

Sustainability and O-Ring Recycling

With environmental compliance on the rise, many companies are asking: Can o rings be recycled?

While used rubber is difficult to reclaim, suppliers are moving toward:

- Eco-friendly elastomers

- Reduced-waste manufacturing

- Take-back programs for industrial clients

Choosing long-life rubber o rings also reduces environmental impact through fewer replacements.

Real-World Example: Hydraulic Equipment Sealing

Challenge: A construction company faced frequent seal failures in hydraulic rams, causing fluid leaks and downtime.

Solution:

- Switched from standard nitrile to low-temperature FKM rubber o rings.

- Added backup rings to reduce extrusion.

- Partnered with a supplier offering technical training for installers.

Result: Reduced seal failures by 85% and improved machine uptime across the fleet.

Final Thoughts: Seal Smarter with the Right O-Ring

From hydraulic presses to food-grade machinery, the o ring plays a critical role in keeping systems sealed, safe, and efficient. With thousands of variations in rubber o rings alone, industrial buyers have more choice than ever—but also more responsibility.

Take time to match the o ring o ring specification to your application. Don’t cut corners on material quality. Invest in a trusted supplier. And educate your team on installation best practices.

In the world of industrial sealing, success is in the details. A well-chosen o ring doesn’t just stop leaks—it drives performance, reduces costs, and supports long-term operational goals.