In the rugged world of construction machinery, hydraulic seals play a crucial role in hydraulic performance, which can make or break productivity. At the core of every efficient system are components like hydraulic cylinder seals, seal cylinder hydraulic setups, and hydraulic pump seals that keep the entire mechanism leak-free and power-efficient. Whether it’s an excavator arm lifting tons of debris or a loader pivoting under pressure, it’s these hydraulic seals that ensure every hydraulic motion runs smoothly.

Choosing the right seal is not just a matter of size or price. It’s a matter of endurance, adaptability, and application-specific engineering. In this guide, we explore what seals work best in construction environments and how to get the most out of them. Know more..

Why Seals Matter in Construction Equipment

Construction equipment operates under extreme conditions—high loads, fluctuating temperatures, dirt, water, vibration, and repetitive motion. This environment is brutal on hydraulic systems.

Without proper hydraulic cylinder seals, machines lose pressure, leak fluid, and suffer from wear, tear, and breakdowns. Incorrect or sub-par seal cylinder hydraulic components reduce operational efficiency, slow down job site progress, and raise maintenance costs.

Even hydraulic pump seals, often hidden deep inside a system, are critical to maintaining internal pressure and preventing contamination.

Key Seal Types in Construction Equipment

Understanding the function of each seal type helps ensure optimal system design and maintenance.

1. Hydraulic Cylinder Seals

These include multiple components:

- Piston seals: Maintain pressure within the cylinder.

- Rod seals: Prevent leakage along the rod.

- Wiper seals: Keep dirt and debris from entering the system.

- Wear rings: Prevent metal-to-metal contact.

Well-designed hydraulic cylinder seals offer long life even under shock loads and side deflection.

2. Hydraulic Pump Seals

These are rotary seals that prevent internal leakage and protect against fluid escape from the pump casing.

- Handle high-speed rotation and high fluid pressure.

- Typically made from advanced elastomers or PTFE composites.

Strong hydraulic pump seals help maintain volumetric efficiency and pressure stability in construction machinery.

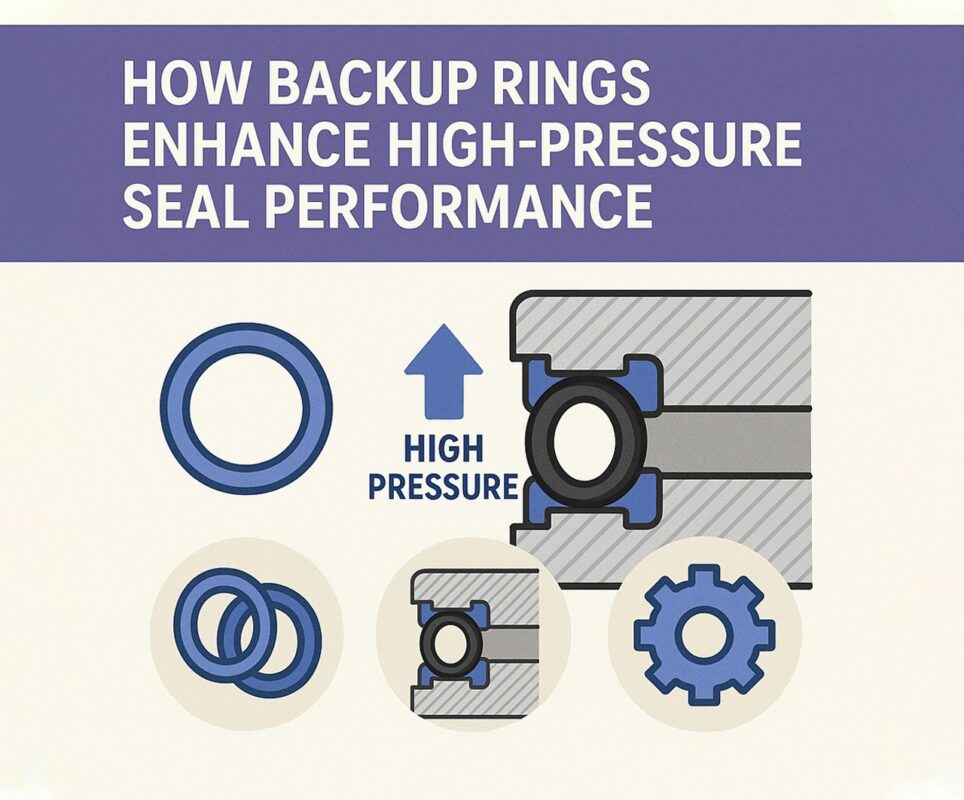

3. Static Seals

Used in flanges, ports, and housing interfaces. They include O-rings and back-up rings.

While these aren’t part of the dynamic motion, poor sealing here can impact the performance of the entire seal cylinder hydraulic system.

What Makes a Seal Effective in Construction Applications?

To survive the tough conditions of a job site, hydraulic seals must offer:

- High wear resistance: To withstand abrasive particles.

- Temperature tolerance: Construction zones can range from freezing mornings to scorching afternoons.

- Shock absorption: Heavy equipment like bulldozers and backhoes face unexpected pressure spikes.

- Chemical resistance: Hydraulic fluid, grease, and environmental chemicals shouldn’t degrade the seal.

- Low friction: Reduces energy loss and wear.

Well-chosen hydraulic cylinder seals or hydraulic pump seals keep construction equipment running longer and better.

Materials That Work Best in the Field

Choosing the right seal material is half the battle won. Here are the top materials suited for harsh construction environments:

1. Polyurethane (PU)

- High tear and abrasion resistance

- Excellent for seal cylinder hydraulic components in cylinders and rams

- Long lifespan under high pressure

2. Nitrile (NBR)

- Good oil resistance and flexibility

- Common for hydraulic pump seals and static seals

3. Viton (FKM)

- High heat and chemical resistance

- Often used in hydraulic pump seals exposed to harsh fluids

4. PTFE (Teflon)

- Extreme temperature range and chemical stability

- Low friction ideal for high-speed rotary seals

5. HNBR and EPDM

- Used for specialized applications where standard materials fail

Advanced formulations and composites now blend multiple materials to extend seal life and performance, especially in compact seal cylinder hydraulic designs.

Top Challenges in Construction Seal Performance

Seals in construction equipment fail for several reasons. Knowing these helps in both selection and maintenance.

1. Abrasion from External Debris

Poor wiper seal performance lets in grit that damages hydraulic cylinder seals.

2. Misalignment

Side loading of pistons or misaligned rods can cause uneven seal wear.

3. Overheating

Overloaded pumps and systems generate heat that damages hydraulic pump seals.

4. Chemical Breakdown

Exposure to incompatible fluids or aggressive cleaners can degrade seal materials.

5. Installation Errors

Improper fitting, twisting, or nicking a seal during install reduces lifespan instantly.

Proactively managing these risks improves seal reliability and helps OEMs and contractors get more from their seal cylinder hydraulic systems.

Tips for Choosing the Right Seal

When selecting seals for construction machinery, consider these practical factors:

- Working Pressure

- Match material and design to expected pressure (up to 5000 psi+ for heavy gear).

- Operating Temperature Range

- Will the equipment be used in sub-zero or desert conditions?

- Speed and Stroke

- Longer stroke = more rod exposure = tougher on rod seals and wipers.

- Environmental Exposure

- Mud, gravel, rain, and dust all impact seal life.

- Fluid Compatibility

- Choose materials that resist breakdown from your specific hydraulic fluids.

- Ease of Installation and Replacement

- Compact seal cylinder hydraulic assemblies may require split seals or specialized designs.

Custom seal kits tailored for specific makes and models can simplify this process.

Innovations and New Developments

Modern seal technology is evolving fast. Here are a few innovations suited for construction equipment:

- Double-lip rod seals: Provide backup sealing in case of primary lip wear.

- Non-metallic wear rings: Reduce scoring and heat.

- Advanced PTFE blends: For higher sealing efficiency under dynamic load.

- Low-friction polyurethane: Increases stroke efficiency, reduces wear.

- Integrated wiper/rod seal units: Simplifies assembly and improves sealing.

These upgrades extend the functional life of hydraulic cylinder seals and reduce the number of interventions on-site.

Maintenance Best Practices for Seal Longevity

- Inspect seals regularly: Look for leaks, scoring, or signs of compression set.

- Keep rods clean: Daily cleaning reduces seal damage.

- Use compatible fluids: Cross-contamination reduces seal integrity.

- Replace worn seals early: Avoid cascading failures.

- Use installation tools: Avoid stretching or nicking the seal.

Well-maintained hydraulic pump seals and rod seals are less likely to cause downtime.

OEMs vs. Aftermarket: Which Seals Are Best?

OEM seals often provide exact-fit assurance, especially in seal cylinder hydraulic systems with complex geometries. However, aftermarket seals with upgraded materials can outperform stock seals in certain applications.

If you operate in extreme conditions, it may be worth sourcing aftermarket hydraulic cylinder seals that prioritize longevity over standard fit.

Look for ISO-certified vendors and industry-standard testing data when comparing.

Real-World Use Case: Excavator in a Quarry

Challenge: Constant exposure to dust and sharp debris caused frequent rod seal failure on an excavator.

Solution:

- Upgraded to polyurethane rod seals with integrated scrapers

- Switched from NBR to HNBR due to better heat resistance

- Added grease flushing ports to reduce particle buildup

Result: Extended service interval from 300 to 700 hours, saving $5,000 annually in maintenance.

It’s proof that the right hydraulic cylinder seals do more than just hold pressure—they protect profits.

Final Thoughts: Seal Smarter, Build Better

In construction, downtime isn’t just inconvenient—it’s expensive. Choosing the right hydraulic cylinder seals, seal cylinder hydraulic configurations, and hydraulic pump seals is a proactive investment in uptime, safety, and efficiency.

From bulldozers to boom lifts, the right seals increase power output, reduce fluid loss, and protect against failure. Whether you’re an OEM, fleet manager, or field technician, understanding what works best for your machines will give you the edge.

Seal smarter—and let your equipment move more dirt, lift more weight, and last longer.