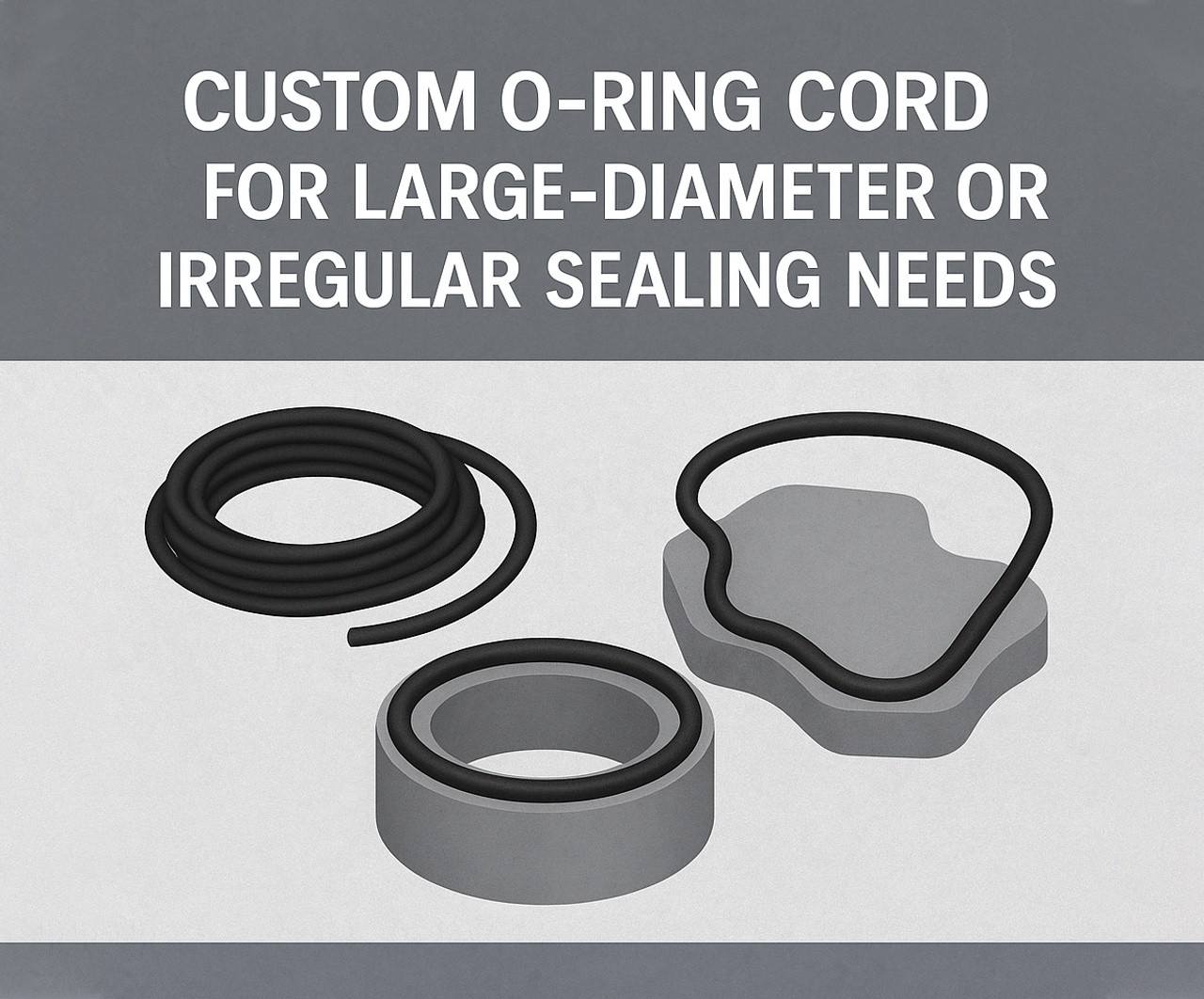

In sealing applications where off-the-shelf solutions won’t cut it, components like o ring cord, cord o ring, and silicone o ring cord become essential. These custom-cut lengths of elastomeric material are a go-to choice for engineers, technicians, and manufacturers dealing with oversized flanges, non-standard grooves, or complex geometries. Whether you’re sealing a massive tank hatch or creating a gasket for a prototype, custom O-ring cord offers flexibility, cost-effectiveness, and reliability in places where traditional O-rings fall short. Know more..

What Is O-Ring Cord?

An o ring cord is a continuous length of elastomer—usually sold by the meter or foot—that can be cut and joined to form a seal of any diameter. The benefit? You get all the sealing performance of a traditional O-ring without being constrained by standard sizing.

Unlike a molded ring, a cord o ring is spliced or vulcanized on-site or in-shop, allowing it to adapt to:

- Large flanges

- Irregular cavities

- Custom groove profiles

A silicone o ring cord in particular is prized for its temperature resistance and flexibility, especially in food-grade, cleanroom, or high-heat applications.

When to Use Custom O-Ring Cord

Not every application fits a catalog part number. Here are the top use cases for cord o ring products:

- Large-Diameter Sealing: When you’re dealing with vessels, tanks, or industrial equipment where diameters exceed typical O-ring stock.

- Prototype Designs: Engineers building new equipment often don’t have final groove dimensions yet.

- Irregular Shapes: Square, oval, or custom-profiled grooves that don’t match standard circular rings.

- Quick Repairs: On-site teams can cut and join a new o ring cord in minutes—no waiting on special orders.

- Extreme Environments: A silicone o ring cord handles high heat, cold, and chemicals better than most other elastomers.

Benefits of Using O-Ring Cord

1. Custom Fit on Demand

Instead of carrying hundreds of O-ring sizes, one spool of cord o ring can be cut to any length. This is a game-changer for field repairs or small production runs.

2. Versatile Material Choices

Choose your o ring cord in:

- Nitrile (NBR)

- Viton (FKM)

- EPDM

- Neoprene

- Silicone

A silicone o ring cord is ideal for FDA applications, medical devices, and high-temperature systems.

3. Easy Storage and Handling

Cords take up less space than boxed O-rings and can be cut to size as needed. That means less inventory, fewer SKUs, and faster response times.

4. Cost Efficiency

Buying and storing every size of traditional O-ring is costly. With cord o ring solutions, you only stock what you need in bulk cord form.

Splicing and Joining Techniques

To turn your o ring cord into a fully functional O-ring, you’ll need to splice the ends. There are two common methods:

1. Cold Splicing

- Uses a cyanoacrylate adhesive.

- Fast and simple.

- Best for low-pressure or static applications.

2. Vulcanized Splicing

- Heat-curing process.

- Stronger bond, ideal for dynamic or high-pressure use.

- Recommended for silicone o ring cord where heat and motion are involved.

Pro tip: Always cut the ends at a perfect 90° and clean thoroughly before bonding.

How to Select the Right O-Ring Cord

- Material Compatibility:

- Nitrile for oils.

- EPDM for water and steam.

- Viton for fuels and chemicals.

- Silicone o ring cord for temperature extremes.

- Hardness (Durometer):

- Softer cords (50-60 Shore A) conform better to irregular grooves.

- Harder cords (70-90 Shore A) resist extrusion under pressure.

- Size and Cross-Section: Measure groove width and depth precisely. Don’t forget stretch and squeeze allowances!

- Color Coding: Many cord o ring materials come color-coded for easy identification—helpful for inventory management.

Common Industries Using Custom O-Ring Cord

- Oil & Gas: Sealing pipe joints, valves, and flanges.

- Pharmaceutical: Sterile sealing with silicone o ring cord.

- Food & Beverage: CIP/SIP processes using FDA-approved silicone.

- Aerospace: Custom cavity sealing for complex geometries.

- HVAC: Gasket sealing in ducting, dampers, and heat exchangers.

Troubleshooting Common Issues

Issue: Joint failure or leaking after installation

- Fix: Recut ends cleaner, apply even adhesive layer, or use vulcanized bonding.

Issue: Seal extrusion or blowout under pressure

- Fix: Choose a harder durometer o ring cord, or consider a backup ring.

Issue: Rapid chemical degradation

- Fix: Verify material compatibility or upgrade to silicone o ring cord or Viton.

Storage Tips for Longevity

- Store cord o ring spools in a cool, dark place.

- Avoid UV exposure (especially for silicone).

- Keep away from ozone sources (electric motors, mercury vapor lamps).

- Label material type and durometer clearly.

Proper storage extends the working life of your silicone o ring cord and other elastomeric cords.

DIY Kit or Custom Fabrication?

DIY Splicing Kit:

- Great for field repairs.

- Cost-effective for small runs.

Factory Vulcanized Cord O Rings:

- Ideal for high-spec applications.

- Superior finish, bond strength, and dimensional accuracy.

Some suppliers offer made-to-order rings with exact specs, including custom groove dimensions and tolerances.

Innovations in Cord O Ring Technology

- Low-outgassing silicone o ring cord for aerospace and cleanrooms.

- Metal-detectable cords for food processing.

- Conductive rubber for EMI/RFI shielding.

- Self-lubricating materials for dynamic seals.

With advances in material science, cord o ring performance continues to expand into new frontiers.

Environmental Considerations

Eco-conscious buyers can now find o ring cord options that are:

- Made from recyclable elastomers

- Produced using solvent-free processes

- Certified for low VOC emissions

For clean manufacturing or green product lines, ask suppliers about sustainable silicone o ring cord options.

Final Thoughts

If you’re dealing with large diameters, custom sealing grooves, or complex shapes, switching to o ring cord, cord o ring, or silicone o ring cord solutions can save time, reduce cost, and improve performance. These versatile, customizable options allow on-demand fabrication and reliable sealing across virtually every industry.

By choosing the right material, mastering your splicing method, and storing cord properly, you can build a better, more adaptable sealing strategy.

Next time you can’t find the perfect O-ring off the shelf, remember: your best solution might already be on the spool.