When it comes to sealing solutions, engineers and manufacturers are spoiled for choice. But understanding the difference between each type of seal can directly affect system performance, downtime, and total cost of ownership. Whether you’re specifying an o ring gasket, choosing an axial o ring, or evaluating innovative QR Seals for your application, knowing the distinct advantages and limitations of each type can help you select the right tool for the job.

In this article, we’ll break down the differences between standard O-rings, X-rings (also known as quad rings), and QR Seals, highlighting their designs, use cases, and how they perform under pressure—literally and figuratively. Know more..

What Is an O Ring Gasket?

The o ring gasket is the most widely used sealing solution in the world—and for good reason. Its simple, circular cross-section creates an effective seal by compressing within a groove between two surfaces. The elastic material (usually rubber, silicone, or fluorocarbon) fills in the microscopic gaps between components to prevent fluid or gas leaks.

Key Benefits of Standard O Rings:

- Low cost and widely available

- Easy to install and replace

- Works well in static and dynamic applications

- Compatible with many materials and sizes

Common Use Cases:

- Hydraulic fittings

- Pneumatic cylinders

- Plumbing

- Aerospace connectors

But while the o ring gasket is effective in many environments, it has its limitations—especially under extreme pressure or in dynamic motion where twisting and extrusion are concerns.

What Is an Axial O Ring?

Unlike the more common radial-sealing o ring gasket, the axial o ring is designed to seal along its axis—meaning the force compresses the ring from the top and bottom rather than the sides. This makes it perfect for face-sealing applications, such as between flat flanges or on screw-top enclosures.

Advantages of Axial O Rings:

- Provides a wide sealing surface

- Ideal for low-pressure face seals

- Simple groove design compared to radial seals

- Reduces risk of over-compression or uneven sealing

Where Axial O Rings Work Best:

- Valve caps

- Pump housings

- Electrical enclosure covers

- Oil fill caps

Designers often overlook the axial o ring, but in flat-face applications, it’s a more reliable and space-efficient option than radial-sealing rings.

What Are X-Rings (Quad Rings)?

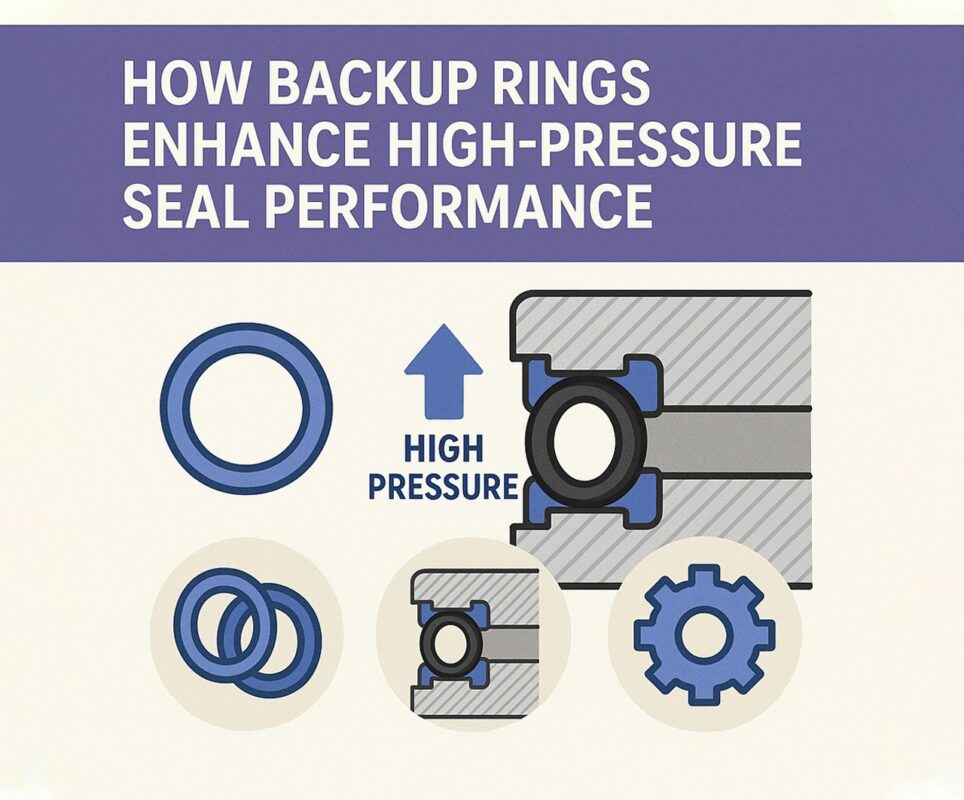

An X-ring, also known as a quad ring, is a four-lobed version of the traditional o ring gasket. Its unique cross-section looks like an “X” or a clover, providing multiple sealing contact points and improved stability under dynamic conditions.

Benefits of X-Rings:

- Reduces rolling and twisting in dynamic motion

- Provides two sealing surfaces instead of one

- Holds lubricant in the valleys between lobes

- Improves sealing under low-pressure conditions

Best Applications:

- Reciprocating hydraulic pistons

- Rotary shafts

- High-cycle pneumatic tools

- Environments with motion or vibration

If your system suffers from o ring gasket failures due to twisting or friction, an X-ring might be the upgrade you need.

What Are QR Seals?

QR Seals are a next-generation sealing technology designed to outperform both traditional o ring gasket and X-ring solutions. They combine advanced geometry and high-performance materials to create seals that are self-energizing, pressure-resistant, and easy to install.

Defining Features of QR Seals:

- Not circular like o ring gasket or X-ring—often asymmetric or engineered with locking features

- Provide reliable sealing under extreme conditions (temperature, pressure, chemicals)

- Designed to resist extrusion, twisting, and wear

- Often include integrated anti-rotation or backup elements

QR Seals are engineered solutions, typically used in industries where failure is not an option—like aerospace, chemical processing, or high-end fluid power systems.

Use Cases:

- Military-grade valve systems

- Deep-sea exploration equipment

- Clean-in-place food processing machinery

- Semiconductor and microfluidic controls

While QR Seals are more expensive than standard options, their long life and zero-failure reputation often justify the cost.

Comparing O Rings, X-Rings, and QR Seals

| Feature | O Ring Gasket | Axial O Ring | X-Ring | QR Seals |

| Contact Points | 1 | 1 | 2 | Custom |

| Motion Resistance | Low | Moderate | High | Very High |

| Pressure Tolerance | Moderate | Low–Moderate | High | Extreme |

| Extrusion Resistance | Low | Low | Moderate | Very High |

| Cost | $ | $ | $$ | $$$ |

| Customization | Low | Medium | Medium | High |

| Maintenance | Easy | Easy | Moderate | Minimal (long intervals) |

How to Choose Between Them

Choose an O Ring Gasket if:

- You need a reliable, general-purpose seal

- The application is static or low-pressure

- Budget and availability are key concerns

Choose an Axial O Ring if:

- You’re sealing flat, face-mounted parts

- Installation space is limited

- You want even compression across a surface

Choose an X-Ring if:

- Your seal moves or vibrates

- You need longer life and reduced friction

- You’re trying to reduce warranty claims

Choose QR Seals if:

- You’re working in extreme pressure or temperature

- You can’t afford seal failure

- You’re seeking next-gen sealing for advanced systems

Creative Engineering Uses for QR Seals

QR Seals are being adopted in cutting-edge applications that push the limits of motion, cleanliness, and efficiency.

1. Clean Energy Systems

Fuel cells and hydrogen tanks require gas-tight, non-contaminating seals. QR Seals handle pressure cycling and extreme cold without compression set.

2. Autonomous Vehicles

In EVs and robotics, small actuator seals must survive millions of cycles. QR’s anti-rotation features prevent failure in tight spaces.

3. Biotech

Lab automation and microfluidics demand pinpoint precision. QR Seals are customized to micron-scale tolerances, outperforming standard seals.

In short, QR Seals offer engineers a way to solve challenges standard elastomer rings simply can’t handle.

Common Mistakes to Avoid

❌ Using the Wrong Groove Size

Many engineers install a standard o ring gasket in a groove designed for an X-ring or axial seal. Always follow manufacturer specs for depth and width.

❌ Ignoring Motion Type

Static seals may not survive dynamic applications. If your system involves reciprocation or rotation, switch from o ring gasket to an X-ring or QR Seals.

❌ Over-Compression

Too much squeeze on any seal—especially an axial o ring—can cause premature wear, cracking, or even seal blowout.

Tips for Better Seal Performance

- Always lubricate seals before installation (unless material-specific advice says otherwise).

- Choose the right durometer (hardness) for your application.

- Verify chemical compatibility between your o ring gasket and process fluid.

- For high-vacuum or aggressive chemical systems, consider QR Seals with FFKM or perfluoroelastomer construction.

Final Thoughts

The humble o ring gasket has served industry for over a century—and continues to do so. But as systems grow more demanding, engineers are increasingly turning to advanced solutions like the axial o ring, X-ring, and cutting-edge QR Seals.

Each has its place. The standard o ring gasket remains unbeatable for cost and simplicity. The axial o ring excels in face-sealing and compact designs. X-rings bring stability and longevity to dynamic systems. And QR Seals push the boundaries of what’s possible in motion control and sealing technology.

In the end, the best sealing solution is one that fits your system, your budget, and your expectations. And when failure isn’t an option—QR has your back.