When it comes to managing high-pressure, high-temperature environments in pumps, mixers, and rotating equipment, 155B and WB2 seals have proven themselves as reliable solutions in the field. Trusted by leading mechanical seal manufacturers, these seal types play a critical role in extending equipment life, maintaining fluid integrity, and minimizing costly leaks. Their precise interaction between the mechanical seal face and the mechanical seal shaft ensures maximum sealing efficiency in even the harshest working conditions.

This article will explore the function, benefits, applications, and design features of 155B and WB2 seals, and explain how they support heavy-duty industrial performance across sectors like oil & gas, mining, chemical processing, and marine. Know more..

What Are 155B and WB2 Seals?

155B Seals:

The 155B is a single-spring, balanced mechanical seal designed for general-purpose and heavy-duty industrial applications. It’s often selected for its adaptability, ease of installation, and robust design, which supports efficient sealing even under high-pressure differentials.

WB2 Seals:

The WB2 is a heavy-duty, dual-balanced cartridge seal with a double-spring or wave spring configuration. It’s widely used in industries requiring API 682 compliance, such as refineries and chemical plants. Known for its back-to-back or tandem configuration capabilities, the WB2 offers outstanding reliability in high-load environments.

Both seals are favorites among mechanical seal manufacturers because they strike a balance between durability, flexibility, and ease of service—making them practical choices for OEMs and maintenance teams alike.

Why Seal Design Matters

Mechanical seals are complex components designed to prevent leakage along the mechanical seal shaft as it rotates, typically in pumps or compressors. The key to their effectiveness lies in the interaction between the rotating and stationary mechanical seal face elements.

If either face becomes damaged, misaligned, or degraded—due to temperature, pressure, or contamination—sealing performance drops rapidly, often leading to catastrophic failure. This is why modern mechanical seal manufacturers invest heavily in face geometry, materials, and design innovation.

Features of the 155B Seal

The 155B mechanical seal is a popular product due to its simplicity and rugged performance characteristics.

Core Advantages:

- Balanced Design: Reduces face load, minimizing wear and extending life.

- Compact Envelope: Fits in tight spaces, making it ideal for retrofit projects.

- Single Coil Spring: Resists clogging and offers consistent loading across the seal face.

- Easy Installation: No special tools or training required—perfect for field servicing.

Because of its efficient mechanical seal face design, the 155B minimizes energy loss and operates smoothly even in challenging environments such as slurry or oil-laden fluids.

Features of the WB2 Seal

The WB2 is engineered for harsh and hazardous environments where failure is not an option.

Core Advantages:

- API 682 Compliance: Meets the highest standards for refinery and process sealing.

- Cartridge Design: Reduces installation error and simplifies servicing.

- Double Springs: Ensures even pressure distribution across the mechanical seal face.

- Dual Seal Options: Can be configured for back-to-back or tandem sealing, increasing reliability.

This type is ideal for highly viscous, corrosive, or volatile fluids, and is frequently supplied by top mechanical seal manufacturers worldwide.

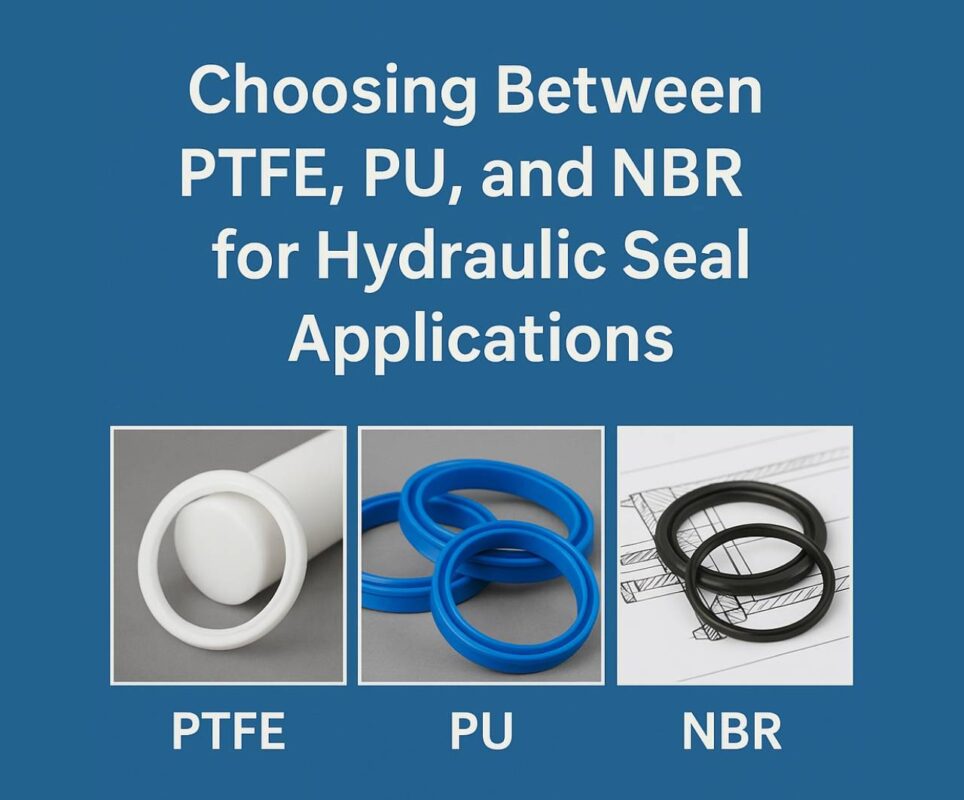

Mechanical Seal Face Materials

Choosing the right mechanical seal face material is essential for both the 155B and WB2.

Common Combinations:

- Carbon vs. Silicon Carbide: General-purpose, chemical resistant

- Silicon Carbide vs. Silicon Carbide: Extreme wear and chemical resistance

- Tungsten Carbide vs. Carbon: High durability, used in abrasive environments

Each combination is designed to work in tandem with the mechanical seal shaft material to reduce friction, control temperature, and minimize wear.

Application Areas

1. Oil & Gas

In drilling rigs and refineries, the WB2 shines due to its API compliance and ability to handle hydrocarbon exposure. Meanwhile, the 155B is often used in auxiliary systems where single-seal applications are sufficient.

2. Chemical Processing

Corrosive fluids, thermal expansion, and strict emission standards require seals that perform under stress. The WB2’s double-seal arrangement ensures zero-leak performance.

3. Mining and Slurry Pumps

Heavy-duty 155B seals are preferred in slurry and tailings applications where clogging and wear are common. Their open coil spring design resists fouling.

4. Marine and Offshore

For shipboard pumps and thruster systems, both 155B and WB2 seals are favored for their dependability and resilience against saltwater corrosion.

Maintenance Considerations

Replacing mechanical seal shaft components is expensive and time-consuming. That’s why maintenance teams choose seals that offer long life and easy servicing.

Maintenance Tips:

- Inspect seal faces regularly for scoring, cracking, or warping.

- Check spring tension in 155B seals to ensure even face pressure.

- Monitor for leakage around the gland plate—a sign of face wear or shaft misalignment.

- Use quality lubricants that match the chemical and thermal profile of your process fluid.

Thanks to pre-engineered cartridge units, WB2 seals are often easier to maintain with fewer alignment issues than traditional pusher-type seals.

The Role of Mechanical Seal Shaft Integrity

Even with the best seal face and spring configuration, a worn or misaligned mechanical seal shaft can cause problems like:

- Seal misfit

- Uneven face loading

- Increased heat generation

- Premature leakage

Ensure your shaft material (typically 316 stainless, duplex steel, or hardened alloy) is corrosion and wear-resistant. Regular shaft inspections during planned downtime can prevent seal failure and unplanned outages.

How Mechanical Seal Manufacturers Drive Innovation

Top mechanical seal manufacturers are innovating in several key areas:

- Additive manufacturing for complex seal face geometries

- Smart sensors embedded into seal housings for predictive maintenance

- Advanced coatings that resist fouling and extend seal life

- Environmentally friendly barrier fluids for double seal systems

OEMs are also working closely with process engineers to develop seal kits custom-fitted for specific operating conditions—whether high vacuum, cryogenic, or high-speed.

Choosing the Right Seal for Your Application

When selecting between the 155B and WB2—or any other seal—you should consider:

- Operating pressure and temperature

- Shaft speed and material

- Fluid type (clean, abrasive, corrosive)

- Space constraints

- Maintenance accessibility

The 155B is ideal for general-purpose sealing with straightforward requirements. The WB2 is better suited for mission-critical applications where dual sealing, API compliance, and extended life are priorities.

Final Thoughts

In industries where uptime, efficiency, and safety are non-negotiable, the role of sealing technology is pivotal. The 155B and WB2 seals represent two ends of the same spectrum—one offering simple, robust performance, and the other pushing the envelope of mechanical seal design. Backed by world-class mechanical seal manufacturers, these components provide reliable sealing between the mechanical seal face and the mechanical seal shaft, safeguarding operations across energy, industrial, and marine sectors.

Understanding your operational demands, material compatibility, and maintenance expectations will help you choose the right sealing solution—and ultimately keep your system running cleaner, longer, and more cost-effectively.