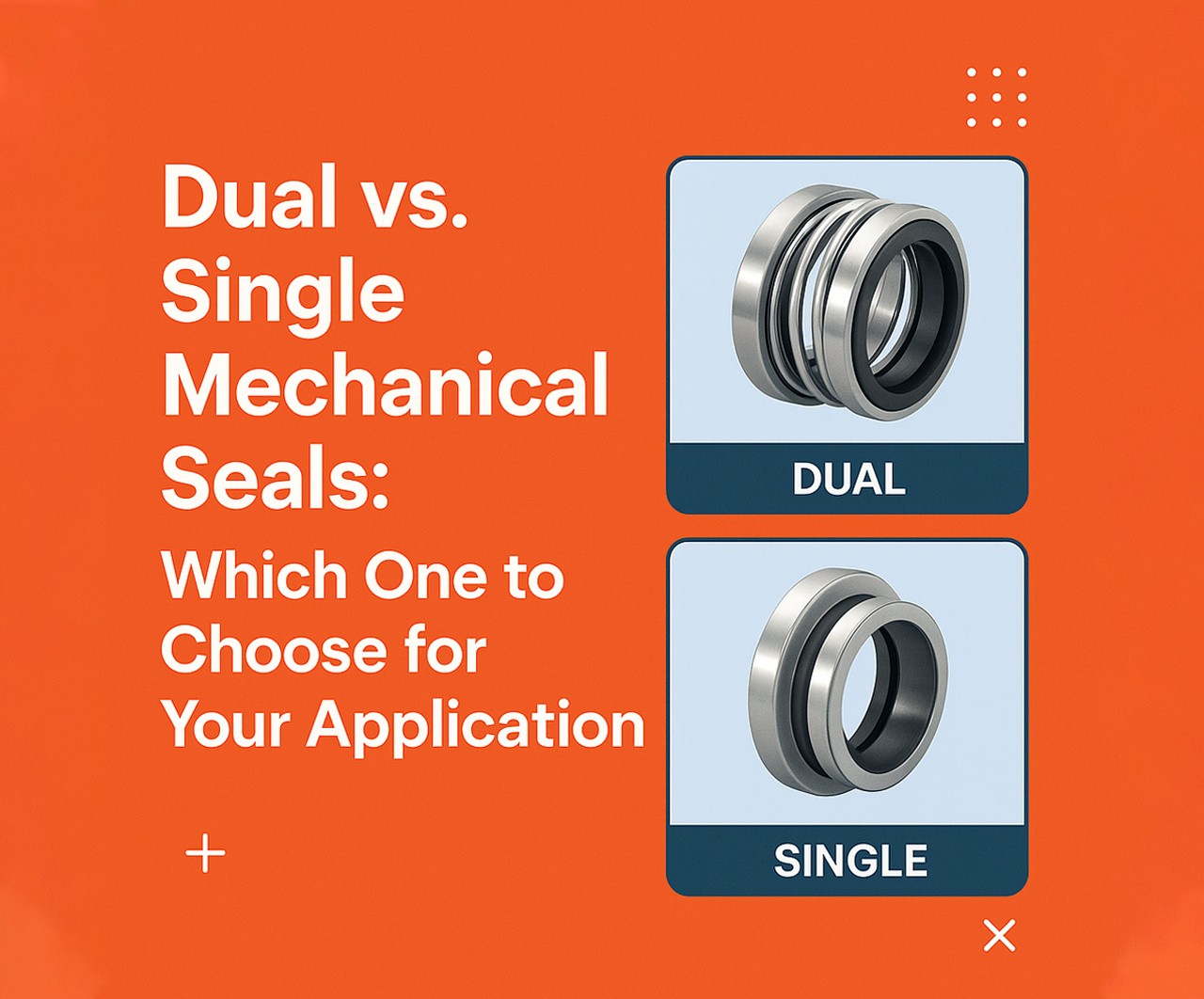

When selecting the right sealing solution for pumps, mixers, or agitators, one of the most critical decisions you’ll face is choosing between a dual mechanical seal, a dual pressurized mechanical seal, or a single mechanical seals. This choice directly impacts not only performance and reliability but also cost, maintenance frequency, and even safety compliance. With each seal type offering distinct benefits and trade-offs, understanding their roles in different operating environments is key to getting the most from your equipment—and your investment.

In this article, we’ll break down the differences, benefits, and best-use scenarios of both dual mechanical seal and single mechanical seal designs, including special insights into the role of the dual pressurized mechanical seal in high-risk or high-value fluid applications. Know more..

Understanding Mechanical Seals: The Basics

Mechanical seals are devices that prevent fluid leakage between a rotating shaft and the stationary pump housing. They do this through two precisely machined seal faces—one rotating with the shaft and one stationary—typically lubricated by the process fluid or a barrier fluid.

Choosing between a single mechanical seal or a dual mechanical seal largely depends on the operating conditions, fluid type, system pressure, and environmental or safety regulations.

What Is a Single Mechanical Seal?

A single mechanical seal is the most basic form of mechanical seal. It consists of one set of seal faces—rotating and stationary—contained within the seal housing.

Advantages of a Single Mechanical Seal:

- Cost-effective

- Easier to install

- Compact design

- Ideal for non-hazardous, clean liquids

Common Applications:

- Water pumps

- HVAC systems

- Irrigation systems

- Non-toxic, low-viscosity fluid processing

Because it relies on the process fluid for lubrication and cooling, a single mechanical seal works best when the liquid is clean, chemically neutral, and doesn’t pose environmental or safety risks if it leaks.

Limitations of Single Mechanical Seals

While cost-efficient, single mechanical seal systems have their downsides:

- Not suitable for toxic or hazardous fluids

- Prone to dry running if fluid flow is interrupted

- Lower pressure and temperature capabilities

- Leakage is possible during operation or shutdown

If your process fluid is aggressive, flammable, or contains solids, relying solely on a single mechanical seal may put your equipment and operators at risk.

What Is a Dual Mechanical Seal?

A dual mechanical seal incorporates two sets of seal faces. These can be arranged in a back-to-back, face-to-face, or tandem configuration, depending on the application. The primary goal is to provide an additional layer of protection and sealing security.

There are two main types:

- Unpressurized (buffered) dual seals

- Pressurized (barrier) dual seals, also known as dual pressurized mechanical seals

Benefits of a Dual Mechanical Seal

- Enhanced reliability and sealing performance

- Suitable for hazardous, abrasive, or high-viscosity fluids

- Complies with environmental safety regulations (API 682, etc.)

- Reduces or eliminates process fluid leakage

- Allows operation in dry or low-lubricity conditions

A dual mechanical seal ensures that even if the inner seal fails, the outer seal will prevent fluid from leaking into the environment. It’s a vital system in applications where downtime, contamination, or leakage must be minimized.

Spotlight: Dual Pressurized Mechanical Seal

The dual pressurized mechanical seal adds an extra level of protection by maintaining a higher pressure in the barrier fluid than in the process chamber. This ensures that in the event of seal face wear or failure, the barrier fluid (usually clean and non-reactive) leaks into the process—not the other way around.

Key Advantages:

- Zero emission of hazardous fluids

- No external contamination enters the process

- Extended seal life

- Ideal for high-risk or expensive fluids

Applications Include:

- Chemical and petrochemical processing

- Pharmaceutical production

- Toxic or flammable fluid containment

- Slurry and abrasive media

While more complex and costly than other designs, the dual pressurized mechanical seal is often a requirement in regulated industries or mission-critical processes.

Single vs. Dual: A Head-to-Head Comparison

| Feature | Single Mechanical Seal | Dual Mechanical Seal |

| Cost | Lower | Higher |

| Complexity | Simple | Complex |

| Maintenance | Easier | Requires barrier/buffer systems |

| Leak Protection | Minimal | Excellent |

| Dry Running Capability | Limited | Yes (if barrier fluid is maintained) |

| Recommended for Hazardous Media | No | Yes |

| Lifespan | Moderate | Extended (with proper maintenance) |

Choosing the Right Seal for Your Application

When deciding between a dual mechanical seal or a single mechanical seal, consider the following factors:

1. Fluid Characteristics

- Is the fluid abrasive, corrosive, or toxic?

- Is it volatile or reactive with air or water?

If yes, opt for a dual pressurized mechanical seal or at least a dual mechanical seal.

2. Operating Conditions

- Are you dealing with high pressure, high temperature, or rapid shaft speeds?

- Will the seal experience dry running?

These factors favor a dual mechanical seal for added durability and safety.

3. Regulatory Requirements

- Does your process fall under strict EPA, OSHA, or FDA guidelines?

If environmental safety or containment is a priority, go with a dual pressurized mechanical seal to meet compliance.

4. Budget and Maintenance Strategy

- Can you afford higher upfront costs for lower long-term maintenance?

- Do you have staff trained to monitor and manage barrier fluid systems?

If yes, a dual mechanical seal may offer the best ROI.

Common Pitfalls to Avoid

❌ Installing a Single Seal in Hazardous Environments

This is one of the most common and dangerous errors. Always evaluate the worst-case failure scenario when selecting a seal.

❌ Using the Wrong Barrier Fluid in Dual Seals

The barrier fluid in a dual pressurized mechanical seal must be compatible with both the inner seal and the process fluid. It should also have adequate lubricating and thermal properties.

❌ Skipping Seal Support Systems

A dual mechanical seal is only as good as the system supporting it. That includes:

- Circulators

- Coolers

- Reservoirs

- Pressure controls

Trends in Mechanical Seal Design

With increasing emphasis on sustainability and efficiency, seal manufacturers are developing:

- Modular dual seal systems for easy retrofitting

- Smart seal monitoring tools (IoT-enabled)

- High-efficiency barrier fluid systems

- Hybrid seal materials to reduce friction and improve wear life

As reliability engineering becomes a bigger focus across industries, the dual mechanical seal is expected to become more common—even in smaller, less regulated systems.

Final Thoughts

In today’s complex industrial environments, the debate between a single mechanical seal and a dual mechanical seal isn’t just about budget—it’s about performance, safety, and reliability. While the single mechanical seal remains a cost-effective solution for clean, non-hazardous fluids, the dual pressurized mechanical seal is essential for harsh, regulated, or high-stakes applications.

If you’re operating in an environment where failure isn’t an option, investing in a dual mechanical seal is not just smart—it’s essential.