When selecting the right sealing solution for rotating shafts in engines, pumps, or gearboxes, understanding the nuances between EC/VCW and KCW oil seals can save time, money, and headaches down the line. Whether you’re searching for oil seals by dimension, browsing top brands like national oil seals, or simply Googling oil seals near me for a fast replacement, knowing the difference between these two common seal types is essential to making an informed decision.

In this guide, we’ll break down the construction, application, benefits, and limitations of EC/VCW and KCW oil seals—helping you decide which one suits your system best. Know more..

What Are EC/VCW and KCW Oil Seals?

Oil seals, also known as rotary shaft seals or radial shaft seals, are critical components that prevent lubricant leakage while blocking contaminants from entering rotating equipment. EC/VCW and KCW are popular types defined by their lip configuration and construction style.

- EC/VCW Seals: Typically single-lip seals with or without a dust lip, often used in applications with moderate contamination risk.

- KCW Seals: Feature dual-lip construction with enhanced dust protection and often include metal case reinforcements for durability under extreme conditions.

Both are widely available and frequently listed among national oil seals, but they differ in how they manage oil retention and environmental exclusion.

Understanding EC/VCW Oil Seals

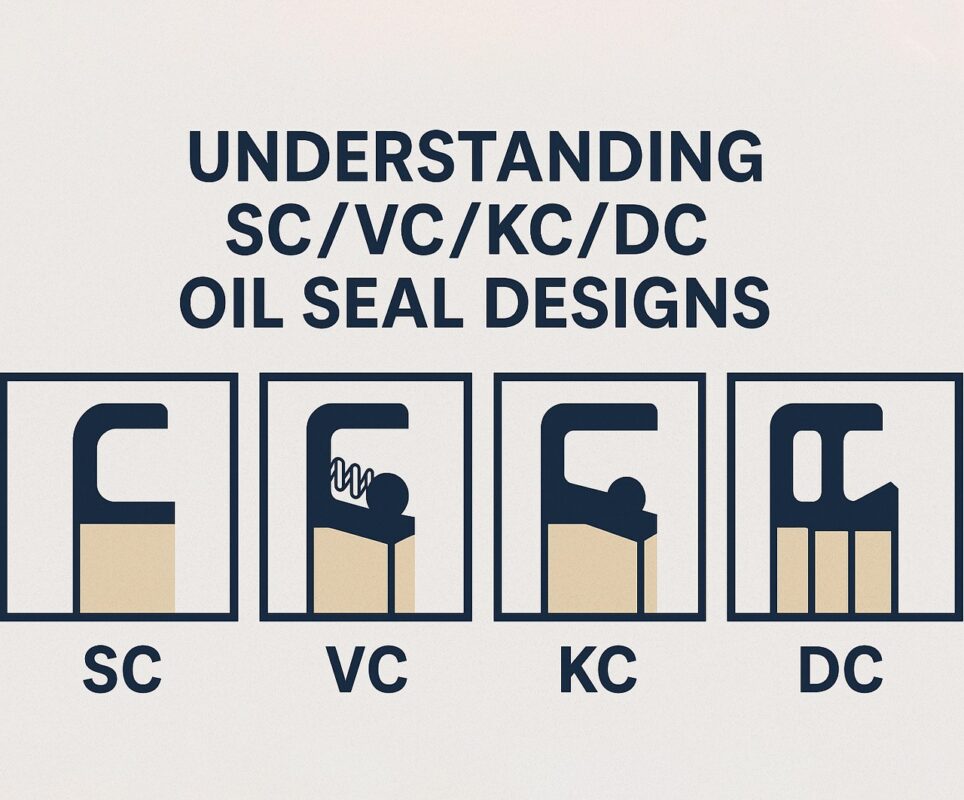

Design and Construction:

EC/VCW seals typically feature a metal outer case, a rubber sealing lip, and sometimes an integrated dust lip. These seals are made for general-purpose use and are a favorite for industries relying on oil seals by dimension when retrofitting or replacing existing units.

Best Applications:

- Automotive crankshafts

- Pumps

- Gearboxes

- Light-duty industrial equipment

Advantages:

- Lower cost compared to heavy-duty seals

- Simplified installation

- Reliable performance in clean or semi-contaminated environments

- Readily available—especially when searching for oil seals near me

Limitations:

- Not ideal for high dust, mud, or abrasive environments

- Lip wear is faster under high speeds or unfiltered systems

Breaking Down KCW Oil Seals

Design and Construction:

KCW oil seals are engineered for more demanding environments. They usually include:

- Dual lips (primary sealing + dust exclusion)

- Reinforced case (metal or high-strength polymer)

- Spring-loaded inner lip for consistent shaft contact

These are often used where seal failure could lead to equipment damage, safety hazards, or system downtime.

Best Applications:

- Off-road machinery (tractors, loaders)

- Industrial mixers

- High-dust conveyor systems

- Construction and mining equipment

Advantages:

- Superior sealing in dirty or wet environments

- Longer service life

- More shaft protection

- Often standard in premium national oil seals lines

Limitations:

- Slightly more expensive

- Require more care during installation to avoid lip damage

Key Differences at a Glance

| Feature | EC/VCW | KCW |

| Lip Configuration | Single or double (optional) | Dual with dust lip |

| Environmental Resistance | Moderate | High |

| Material Options | Nitrile, FKM | Nitrile, FKM, Metal-reinforced |

| Installation | Easy | Moderate (requires alignment) |

| Common Use | General purpose | Harsh, contaminated environments |

| Price | Lower | Slightly higher |

| Availability | Widely available (oil seals by dimension) | Found in top national oil seals lines |

Selecting Oil Seals by Dimension

No matter which type you choose, getting the right size is critical. That’s where oil seals by dimension come into play. The key measurements include:

- Inside diameter (ID) – Matches shaft size

- Outside diameter (OD) – Matches housing bore

- Width/thickness – Overall seal depth

Whether you need a replacement or building a new system, top suppliers often list products in detailed oil seals by dimension charts for easy comparison.

Why National Oil Seals Matter

National oil seals is more than a popular search term—it’s a go-to brand known for quality, consistency, and wide availability. Many EC/VCW and KCW seals on the market today are based on National’s designs or are directly supplied under their brand.

Benefits of Choosing National Oil Seals:

- Backed by years of R&D

- Available globally (including local distributors if you’re searching oil seals near me)

- Meet or exceed OEM standards

- Excellent technical support and documentation

Their extensive catalog makes finding EC/VCW or KCW seals easier, especially when matching parts via oil seals by dimension.

Local Search: Oil Seals Near Me

Sometimes, you don’t have the luxury to wait for a delivery—especially during unplanned downtime. That’s when searching oil seals near me becomes essential.

Tips for Local Buying:

- Look for industrial supply shops or bearing distributors

- Have your dimensions and specifications ready

- Ask for cross-references to national oil seals or equivalents

- Verify compatibility with EC/VCW or KCW standards

Some distributors even offer emergency delivery or same-day pickup, making oil seals near me more than just a convenience—it’s an operational lifesaver.

Material Considerations

Both EC/VCW and KCW seals are available in multiple materials. Your selection should align with the application’s temperature, chemical exposure, and speed.

Common Materials:

- Nitrile (NBR): Great for oil and grease, up to ~100°C

- Viton (FKM): Resistant to high temperatures and aggressive chemicals

- Silicone: Flexible and stable in extreme cold

- PTFE (Teflon): Low friction, good for high-speed shafts

Whether you’re checking specs online or talking to suppliers about oil seals near me, always match material type to the conditions the seal will face.

Installation Tips for Long-Lasting Performance

Proper installation is just as important as choosing the right type.

Best Practices:

- Clean shaft and bore thoroughly before installation

- Lubricate the seal lips with oil or grease (compatible with the system fluid)

- Use a seal driver—not a hammer—to prevent lip deformation

- Avoid over-compressing the seal during installation

Misalignment or contamination during install is one of the top causes of premature seal failure—even for high-end national oil seals.

Maintenance and Replacement

Routine checks can prevent costly failures:

- Inspect shaft surface for wear or scoring

- Replace seals if they show signs of hardening, cracking, or leakage

- Consider upgrading from EC/VCW to KCW if contamination increases over time

If in doubt, search oil seals near me or consult your local distributor to confirm if KCW seals will provide added protection in changing environments.

Future of Oil Seals: Smarter Materials, Longer Life

As machinery gets more compact and demands increase, oil seals must also evolve. Expect to see:

- Composite lip materials for lower friction

- Embedded RFID tags for lifecycle tracking

- Adaptive seal profiles that change shape under pressure

- Sustainable sealing solutions using recyclable or low-emission materials

Even standard options like EC/VCW and KCW are being refined by major players like national oil seals, who continue to innovate while preserving backward compatibility.

Final Thoughts: Which One Should You Choose?

- Choose EC/VCW seals if you’re working with clean environments, moderate speeds, and standard shaft conditions. They’re cost-effective, easy to install, and widely available via oil seals by dimension listings and oil seals near me suppliers.

- Choose KCW seals if you’re dealing with dirty, abrasive, or high-load systems. They offer better protection and longer life, and are backed by trusted brands like national oil seals.

Ultimately, the decision should balance cost, performance, and environment. In some cases, upgrading to KCW might save money long-term by reducing maintenance and avoiding failures.