Whether you’re searching for a reliable parker oring, comparing plumbing parts like a wax ring Home Depot special, or even deep-diving into niche queries like pinky rings for men meaning, it’s surprising how often the term “ring” can mean vastly different things. But in the world of engineering and sealing, O-rings are anything but ornamental. These small but mighty components play a crucial role in fluid and gas sealing systems—and their cross-section shape can make or break system performance.

In this guide, we’ll explore the most common O-ring cross-section shapes—round, X (quad), square, and more—and help you decide which design suits your application best. Know more..

What Is an O-Ring Cross-Section?

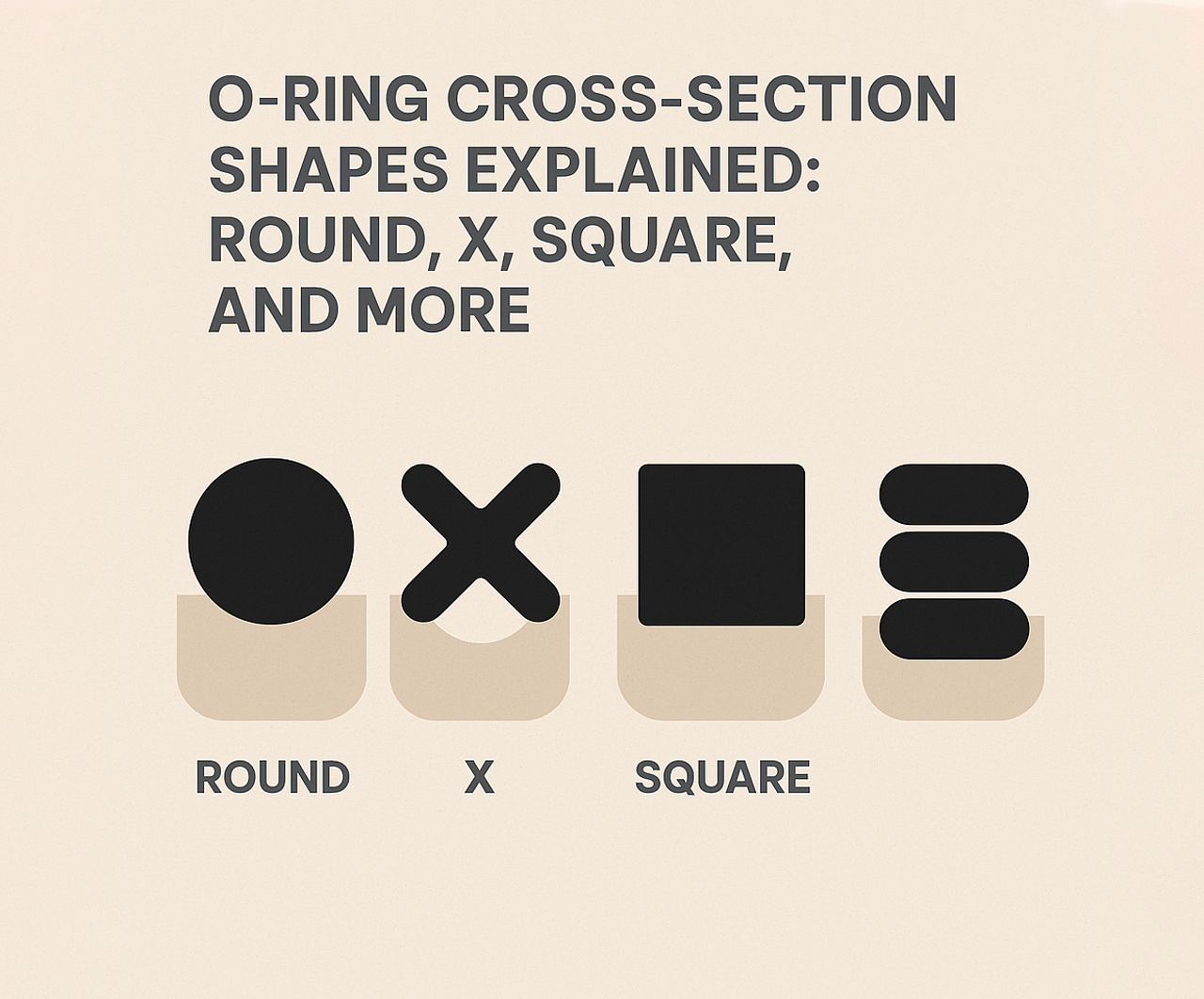

An O-ring’s cross-section refers to its profile shape when you cut it perpendicular to the circular path. While the term “O-ring” traditionally refers to a round cross-section, there are actually several geometric variations engineered for different sealing conditions, pressures, and dynamic forces.

Whether you’re choosing a parker oring for hydraulic equipment or browsing alternatives to a wax ring Home Depot uses for toilets, understanding the cross-section design will lead you to the right choice.

1. Round Cross-Section O-Rings

Overview:

This is the most common and widely used O-ring shape. It’s easy to manufacture, offers reliable sealing for both static and dynamic applications, and is available in thousands of sizes and materials.

Key Features:

- Circular cross-section

- Available in both imperial and metric sizes

- Suitable for radial and axial sealing

Best Uses:

- Hydraulic cylinders

- Pumps and valves

- Aerospace systems

- General-purpose sealing

Advantages:

- Cost-effective

- Wide availability (especially through brands like parker oring)

- Easy to install and replace

Pro Tip: Round O-rings are often used as the default sealing choice unless high pressure or wear resistance dictates another shape.

2. X-Rings (Quad Rings)

Overview:

X-rings, also known as quad rings, feature an “X” shaped cross-section. They offer four contact points instead of two (like in round O-rings), improving sealing and reducing rolling or twisting during installation.

Key Features:

- X-shaped profile

- Stable under dynamic loads

- Reduced risk of spiral failure

Best Uses:

- Pneumatic pistons

- Rotary shafts

- High-speed dynamic applications

Advantages:

- Enhanced sealing under motion

- Lower friction than traditional round O-rings

- Excellent for high-pressure environments

Fun Fact: The X shape helps trap lubricant, reducing wear—ideal for motion-intensive applications. While less common at your local wax ring Home Depot aisle, they’re a staple in high-performance machinery.

3. Square Rings

Overview:

These O-rings feature a square or rectangular cross-section. They’re often used in static applications or where standard grooves already accommodate square profiles.

Key Features:

- Flat-sided sealing surface

- Maximized contact area

- Ideal for flange seals

Best Uses:

- Static joints

- Electrical connectors

- Some valve assemblies

Advantages:

- Greater sealing area

- Resistance to extrusion

- Can be retrofitted in standard O-ring grooves

While not as glamorous as exploring the pinky rings for men meaning, square rings hold serious value in engineering circles—particularly in custom or modified sealing grooves.

4. D-Rings

Overview:

D-rings have a semi-circular profile with one flat side. The flat side stabilizes the ring against motion or rolling within the groove.

Key Features:

- One flat edge, one rounded

- Resists twisting during installation

- Ideal for axial sealing

Best Uses:

- Automotive systems

- Fuel injectors

- Marine equipment

Advantages:

- High stability

- Reduces friction in reciprocating applications

- Can be used where groove tolerances are loose

D-rings may be rare among pneumatic cylinder kits but are often specified in custom OEM systems, especially those with alignment-sensitive sealing areas.

5. T-Rings and V-Rings

T-Rings:

T-rings are enhanced versions of X-rings, often used with anti-extrusion rings. These offer the benefits of X-rings but with added support under high-pressure loading.

V-Rings:

Used mostly as rotary shaft seals, these flexible, self-energizing seals prevent contamination entry and work well in conjunction with lip seals.

Best Uses:

- Heavy-duty hydraulic systems

- Mining equipment

- Industrial turbines

You won’t see these listed under wax ring Home Depot, but you’ll certainly find them in the catalogs of parker oring and other industrial-grade manufacturers.

Choosing the Right Cross-Section: Key Factors

1. Application Type

- Static Seals: Round and square cross-sections usually suffice.

- Dynamic Seals: Use X-rings or D-rings to handle motion with reduced friction and wear.

2. Pressure

- Higher pressures often require X-rings or back-up rings with square O-rings.

3. Temperature

- Ensure material compatibility across all cross-section shapes. For example, silicone for cold applications, Viton for heat.

4. Groove Compatibility

- Not all grooves are compatible with every shape. Ensure that your groove design supports the profile of your selected O-ring.

When unsure, consult with a technical advisor or browse parker oring sizing charts and material guides to match groove width, compression, and application environment.

Where to Buy O-Rings and Sealing Kits

Depending on your needs, there are several ways to find what you’re looking for:

Local Retail:

- Hardware stores like wax ring Home Depot may carry round-profile rubber seals, often for plumbing or home repair.

- Good for emergency fixes or DIY solutions.

Online Marketplaces:

- Amazon, McMaster-Carr, and Grainger carry a wide variety of shapes and materials.

Professional Suppliers:

- Industrial and engineering suppliers, especially certified parker oring distributors, provide extensive inventory and application support.

Specialized Rings:

Still wondering about niche ring meanings? If you’re on a completely different track—like learning about pinky rings for men meaning—you’ll find symbolism, status, and fashion instead of pressure specs and groove tolerances.

Maintenance and Installation Tips

- Clean Surfaces Thoroughly Remove dust, oil, or debris before installing any O-ring.

- Use the Right Lubricant Apply an appropriate lubricant to reduce installation friction and avoid twisting—especially with pneumatic or hydraulic o-rings.

- Avoid Overstretching Stretching seals too far during installation can permanently deform their profile.

- Inspect for Damage Check for cuts or flattening after insertion.

Custom O-Rings: When Off-the-Shelf Doesn’t Cut It

Some applications demand more than standard sizing. Custom cross-sections or composite seals (combining rubber and metal or plastic) can be designed to meet strict tolerances, chemical compatibility, or mechanical loads.

Custom O-rings are often requested through:

- OEM partnerships

- Defense or aerospace contractors

- Cleanroom manufacturing systems

In these cases, going through parker oring custom design services or working with an application engineer ensures performance, compliance, and reliability.

Final Thoughts: More Than Just a Ring

The cross-section of an O-ring might seem like a small detail, but it can significantly influence the sealing system’s reliability, longevity, and efficiency. From the familiar round shape to the specialized X-ring or D-ring, each profile exists for a reason—and choosing the wrong one can lead to system failure, leaks, and downtime.

So next time you’re shopping for a parker oring, comparing sizes to a wax ring Home Depot offering, or just curious about what a pinky rings for men meaning might symbolize, remember that rings—whether in mechanics or style—are all about fit, function, and form.