When discussing seal technology in modern fluid power systems, the conversation almost always circles back to O-rings. From compact pneumatic valves to high-pressure hydraulic cylinders, these small yet vital components are crucial to system integrity and performance. But did you know that even phrases like ring on thumb meaning can mislead engineers searching for critical seal information? That’s why it’s essential to focus on technical accuracy. Whether you’re comparing gaskets and o rings or specifying replacements labeled under gaskets & o rings, understanding the real role of O-rings in dynamic systems is key to reliability, efficiency, and safety.

This article unpacks the function, materials, selection criteria, and application-specific considerations for O-rings used in both hydraulic and pneumatic environments. Whether you’re a design engineer, a procurement manager, or a maintenance tech, this guide is your roadmap to smarter O-ring usage. Know more..

Why O-Rings Matter in Fluid Power Systems

O-rings serve as a primary line of defense against fluid leakage. Unlike gaskets and o rings used in static flange applications, dynamic O-rings are placed in moving parts — such as pistons, rods, and rotary shafts — where sealing performance under pressure is non-negotiable.

These versatile rings:

- Prevent fluid leaks

- Maintain system pressure

- Protect components from contamination

- Minimize wear on moving surfaces

While some confuse the ring on thumb meaning with symbolism or jewelry, in the world of engineering, the “ring” is all about sealing precision.

Key Applications for O-Rings

1. Hydraulic Systems

- Environment: High pressure, variable temperatures, fluid compatibility challenges

- Application Points: Cylinder heads, pumps, valves, control manifolds

2. Pneumatic Systems

- Environment: Lower pressure, faster cycling, dry media

- Application Points: Actuators, solenoid valves, air compressors

The performance difference between gaskets & o rings becomes especially important in dynamic hydraulic systems where motion, pressure, and fluid aggression test seal limits.

Material Matters: Choosing the Right Compound

O-ring performance is directly tied to the material. Below are some common elastomers and their characteristics:

| Material | Temp Range (°C) | Best For |

| Nitrile (NBR) | -40 to +120 | General hydraulic fluids |

| Viton (FKM) | -20 to +200 | High temp, chemical resistance |

| EPDM | -50 to +130 | Brake systems, water-based fluids |

| Silicone | -60 to +200 | Low pressure, dry air applications |

| HNBR | -40 to +150 | Automotive, oil & gas |

If you’re sourcing from suppliers categorized under gaskets and o rings, make sure their material specs are certified and traceable.

The Difference Between Gaskets & O Rings

Though often lumped together in product listings, gaskets & o rings are not the same:

- Gaskets: Flat seals used in static, flange-based joints. Handle compression but not movement.

- O-Rings: Circular cross-section seals used in both static and dynamic applications. Designed to fit grooves and withstand pressure.

Selecting the wrong type due to mislabeling in gaskets and o rings catalogs can lead to catastrophic system failures.

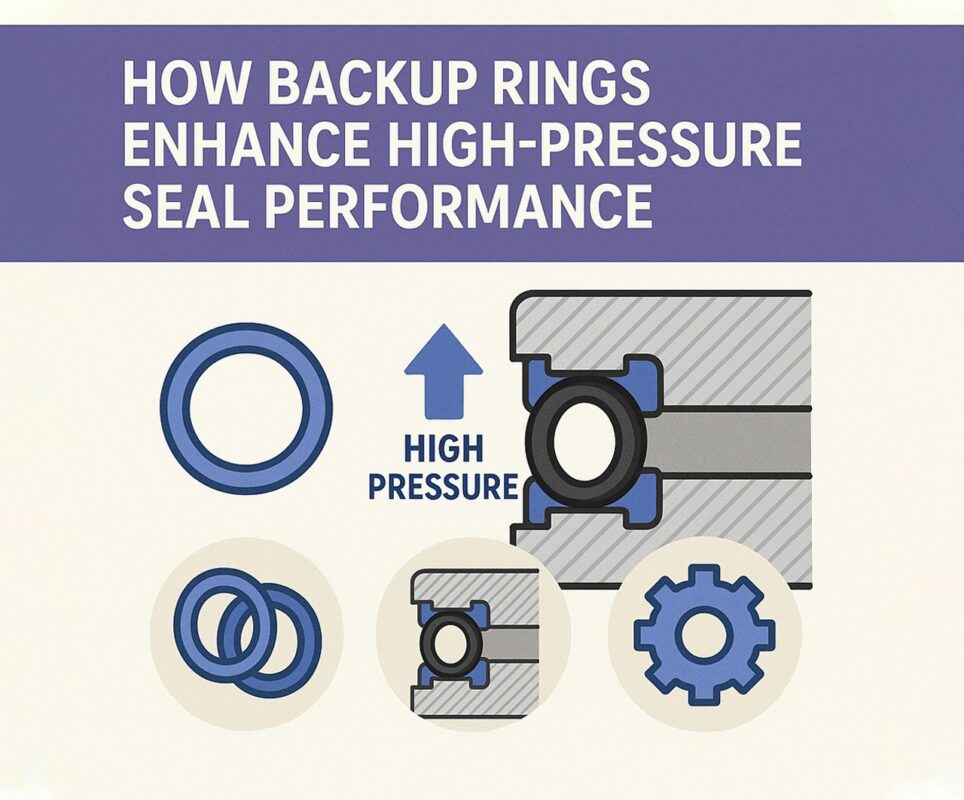

Pressure and Groove Design

Proper groove design ensures that O-rings are compressed enough to seal but not so tight that they degrade prematurely.

Considerations Include:

- Squeeze Ratio: Amount of compression based on groove size

- Stretch: Allowance for installation

- Clearance Gaps: To prevent extrusion under pressure

Hydraulic grooves typically need deeper cuts and anti-extrusion back-up rings for high-pressure environments. Pneumatic grooves may prioritize tighter tolerances for air retention.

Surface Finish and Tolerance

The mating surfaces where the O-ring seals must have:

- Surface finish between Ra 0.2–0.8 µm

- Proper roundness and concentricity

Too rough, and the O-ring wears prematurely. Too smooth, and the O-ring might not seat correctly.

Lubrication: More Than Just Grease

Using compatible lubricants improves:

- Installation ease

- Wear resistance

- Friction reduction

Hydraulic systems often use system fluid as lubricant. Pneumatic systems may require grease that doesn’t evaporate or react with dry air.

Avoid using petroleum-based lubricants on EPDM or silicone materials — a common oversight when sourcing from unverified gaskets and o rings vendors.

Signs of O-Ring Failure

Even the best O-rings eventually fail. Here’s what to watch for:

| Symptom | Likely Cause |

| Cracking | Heat or chemical incompatibility |

| Flattening | Over-compression or age |

| Spiral Failure | Twisting during installation |

| Extrusion | Excessive pressure, improper groove |

| Abrasion | Poor lubrication or surface finish |

Conduct regular maintenance and replace any damaged O-rings with verified parts — preferably sourced through vetted gaskets & o rings distributors.

How to Select the Right O-Ring

Step-by-Step Process:

- Define your fluid type – Water, oil, air, chemicals?

- Identify the pressure range – Static or dynamic? Low or high?

- Determine the temperature envelope – Operating and ambient.

- Choose the material – Based on chemical compatibility and temp.

- Design the groove – Use manufacturer’s compression and gap specs.

A seasoned engineer will treat O-ring selection with the same level of care as component sizing or flow rate calculations.

Case Study: O-Rings in a Mobile Excavator

A fleet of mobile excavators operated in mixed weather zones reported repeated hydraulic leaks. Upon inspection, O-rings rated for 80°C were found in an application that spiked to 120°C.

By switching to Viton-based O-rings and verifying installation groove specs, the maintenance interval tripled, saving over $50,000 in unscheduled repairs.

Moral of the story: Don’t be misled by broad product listings in gaskets & o rings catalogs. Know what you need and source accordingly.

The Role of Quality Suppliers

Good suppliers do more than ship parts — they guide selections. When searching for O-rings, avoid confusion with unrelated results like “ring on thumb meaning” and instead focus on:

- Tech support

- Application-specific materials

- Custom packaging and traceability

Stick to suppliers who specialize in gaskets and o rings, not generic industrial catalogs.

Final Thoughts

O-rings may look simple, but their performance in hydraulic and pneumatic systems is anything but. Choosing the right material, size, groove design, and installation technique determines whether your system runs like clockwork or grinds to a halt.

Avoid the confusion that comes from generalized searches like “ring on thumb meaning” and focus on technical terms. Whether you’re buying online or consulting with an expert on gaskets and o rings, always prioritize quality and compatibility.

By working with reputable suppliers, investing in the right materials, and paying close attention to design specs, you can drastically increase system uptime and extend equipment lifespan.