In today’s fast-paced manufacturing world, injection molding systems are constantly pushed to the limits of heat, pressure, and cycle speed. To keep up with this intensity, sealing components must be optimized for extreme conditions. Whether you’re working with FFKM O rings, flat O rings, or high temp O rings, integrating backup rings into the seal design is a game-changer for longevity, reliability, and performance. These unsung heroes prevent seal extrusion and distortion in high-load applications, particularly where precision and repeatability are mission-critical. Know more..

Why Backup Rings Are Essential in Injection Molding

Injection molding systems generate enormous pressures and heat during each cycle, especially at the screw tip, barrel interface, and hydraulic control systems. Seals must contain these forces without breaking down. A common failure point? O-ring extrusion into the small gaps between metal surfaces, which leads to seal damage, system leaks, and unplanned downtime.

That’s where backup rings come in. Positioned adjacent to FFKM O rings or high temp O rings, backup rings provide mechanical support to keep seals in place and maintain proper shape under load.

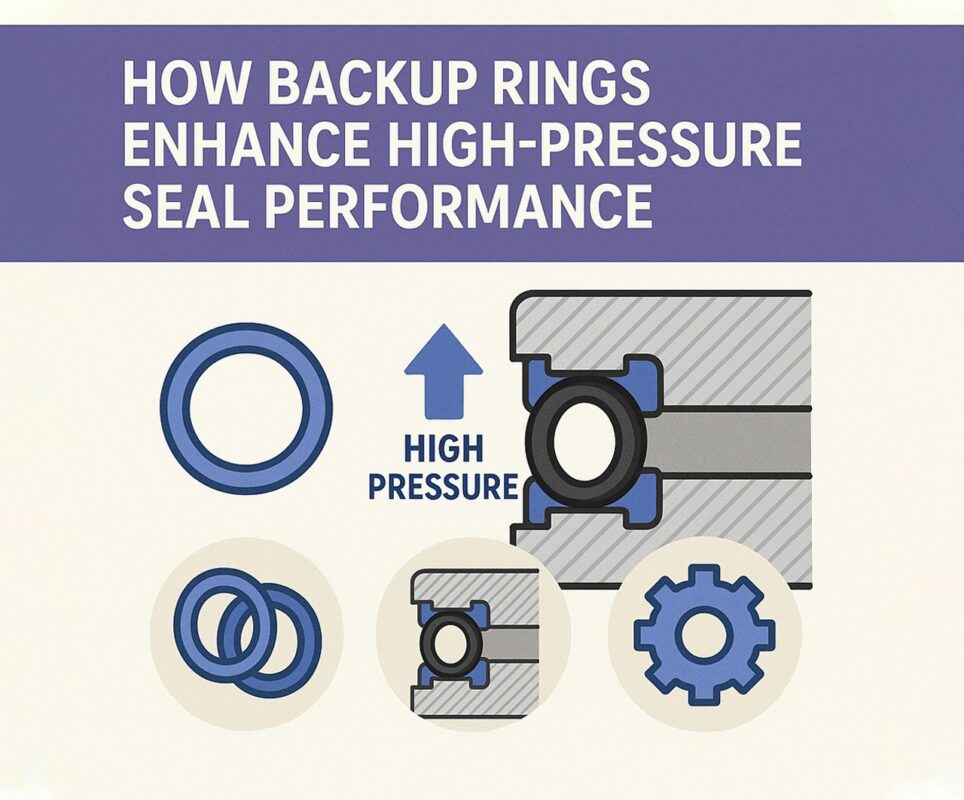

Understanding the Backup Ring Advantage

A backup ring is a rigid, usually non-elastic ring placed next to an O-ring on the low-pressure side. In bidirectional pressure environments (like hydraulic actuators in injection molding), rings are placed on both sides.

Key Functions:

- Prevent extrusion of the O-ring into clearance gaps

- Support O-ring during high-pressure injection cycles

- Allow use of softer O-ring materials for better compression sealing

- Reduce premature seal wear

Without a backup ring, even the most resilient FFKM O rings may suffer damage after just a few high-pressure cycles.

Types of Backup Rings Used in Molding Systems

1. Solid Backup Rings

- Made from materials like PTFE, PEEK, or Nylon

- Used in static sealing applications with minimal groove flex

2. Split Backup Rings

- Easier to install in closed grooves

- Ideal for retrofitting older mold designs

3. Contoured Backup Rings

- Designed with a precise profile to reduce stress concentrations

- Often custom-fit to match complex groove geometries

These are matched with various O-ring profiles, including round and flat O rings, based on specific design needs.

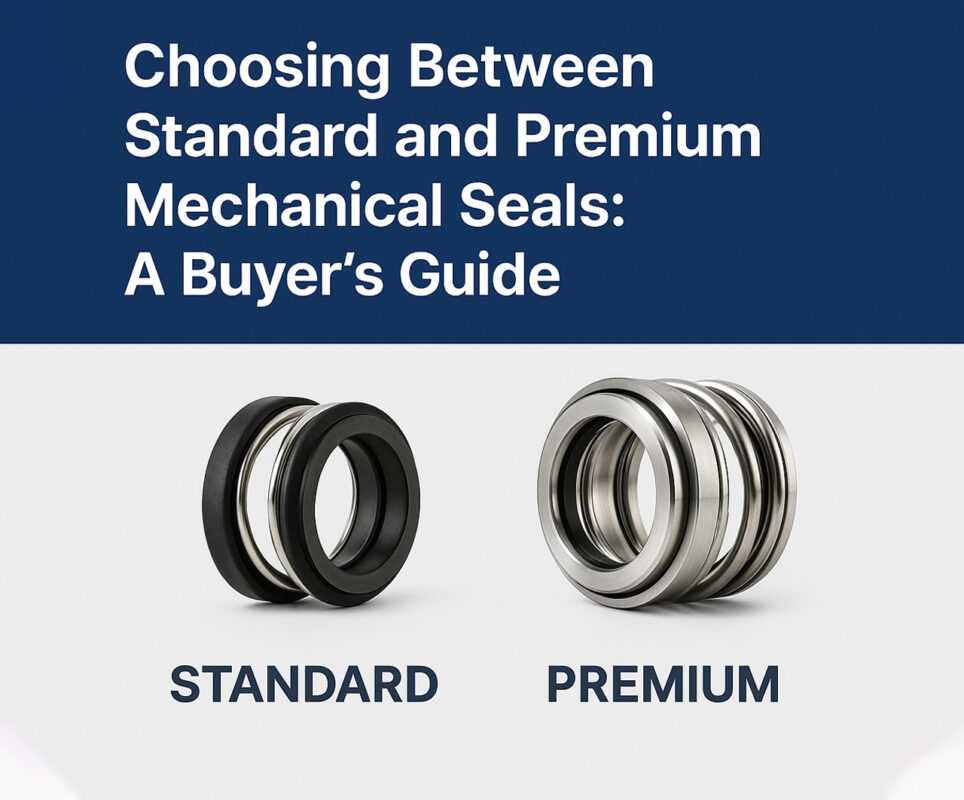

Choosing the Right Material: FFKM vs. High Temp Rubber

When specifying a seal for injection molding:

- FFKM O rings (perfluoroelastomers):

- Extreme chemical resistance

- Temp range: up to 327°C

- Ideal for aggressive plastics and solvents

- High temp O rings (like Viton or Silicone):

- Good for temperatures up to 200–250°C

- Cost-effective alternative for less aggressive media

- Flat O rings:

- Used in limited space applications

- Require backup support due to broader sealing surface

Where Backup Rings Are Critical in Injection Molding

- Hydraulic Cylinders and Actuators Backup rings in piston and rod seals prevent seal blowout during pressure spikes and help maintain machine response accuracy.

- Nozzle and Barrel Interfaces Seals exposed to molten resin temperatures benefit from rigid backup support to maintain form and function.

- Rotary Injection Screws High-speed rotational motion and back-pressure demand both high temp sealing and extrusion protection.

- Hot Runner Manifolds Complex temperature and chemical exposure profiles make backup rings essential alongside FFKM O rings.

Installation and Groove Design Tips

Proper backup ring performance starts with correct installation:

- Match the ring to groove dimensions: Avoid excess compression or misfit.

- Place on correct side of O-ring: On the low-pressure side, unless pressure is bidirectional.

- Use dual rings for dynamic motion: Especially in reciprocating seals.

- Pair with right O-ring material: E.g., PTFE backup ring with FFKM O rings in aggressive environments.

Real-World Case Study: High-Speed Mold Press

An automotive parts manufacturer faced repeated failures of high temp O rings in a high-speed mold press. After a root-cause analysis, engineers added contoured PTFE backup rings to the O-ring grooves:

Results:

- O-ring lifespan increased from 3 weeks to 3 months

- Cycle time improved by 15% (less downtime)

- No seal extrusion during 1 million+ cycles

This simple upgrade paid back the investment in under a month.

Backup Rings and Seal Innovation

Modern backup rings are evolving with injection system demands:

- Textured or grooved surfaces: Reduce thermal stress on O-ring

- Spring-loaded variants: Provide adaptive support under variable pressure

- Low-friction coatings: Improve dynamic performance and ease installation

These design trends help support the next generation of FFKM O rings and flat O rings in extreme-use applications.

Why Flat O Rings Need Extra Support

While most people associate O-rings with round profiles, flat O rings are increasingly used in:

- Narrow or non-standard grooves

- High surface area sealing

- Applications where minimal squeeze is needed

However, their large contact footprint makes them vulnerable to side-loading and extrusion, which is why backup rings are crucial in these setups.

Maintenance and Monitoring

Even the best seals degrade. Here’s how to maximize system life:

- Visual inspection: Look for nicks, flattening, and extrusion

- Cycle count tracking: Replace seals proactively based on molding cycle limits

- Temperature and pressure logs: Ensure system parameters stay within O-ring rating

- Use wear markers: Some advanced backup rings change color as wear indicator

Backup Ring Material Chart

| Material | Temp Range | Chemical Resistance | Best Use |

| PTFE | -200°C to 260°C | Excellent | High-temp, inert media |

| PEEK | -50°C to 250°C | Excellent | High-pressure, chemical environments |

| Nylon | -40°C to 120°C | Good | Economical, moderate heat |

Common Misconceptions

- Backup rings are optional: Not in high-pressure systems—they’re essential for O-ring survival.

- All O-ring profiles perform the same: Not true. Flat O rings require special attention to prevent sealing surface fatigue.

- High temp O rings don’t need support: They still deform under pressure and benefit from rigid backup.

Final Thoughts: Seal It Strong, Seal It Smart

Backup rings are the silent partners to O-rings in high-performance injection molding systems. When dealing with molten polymers, hydraulic thrust, or non-stop production, your sealing strategy can’t rely on elastomers alone. Whether you’re using FFKM O rings for their unbeatable chemical resistance, flat O rings for compact grooves, or high temp O rings in hot zones, adding a backup ring ensures your seals survive the pressure.

In a world where downtime costs thousands per hour, prevention pays. And backup rings are one of the smartest, simplest investments you can make to protect your high-load injection molding system.