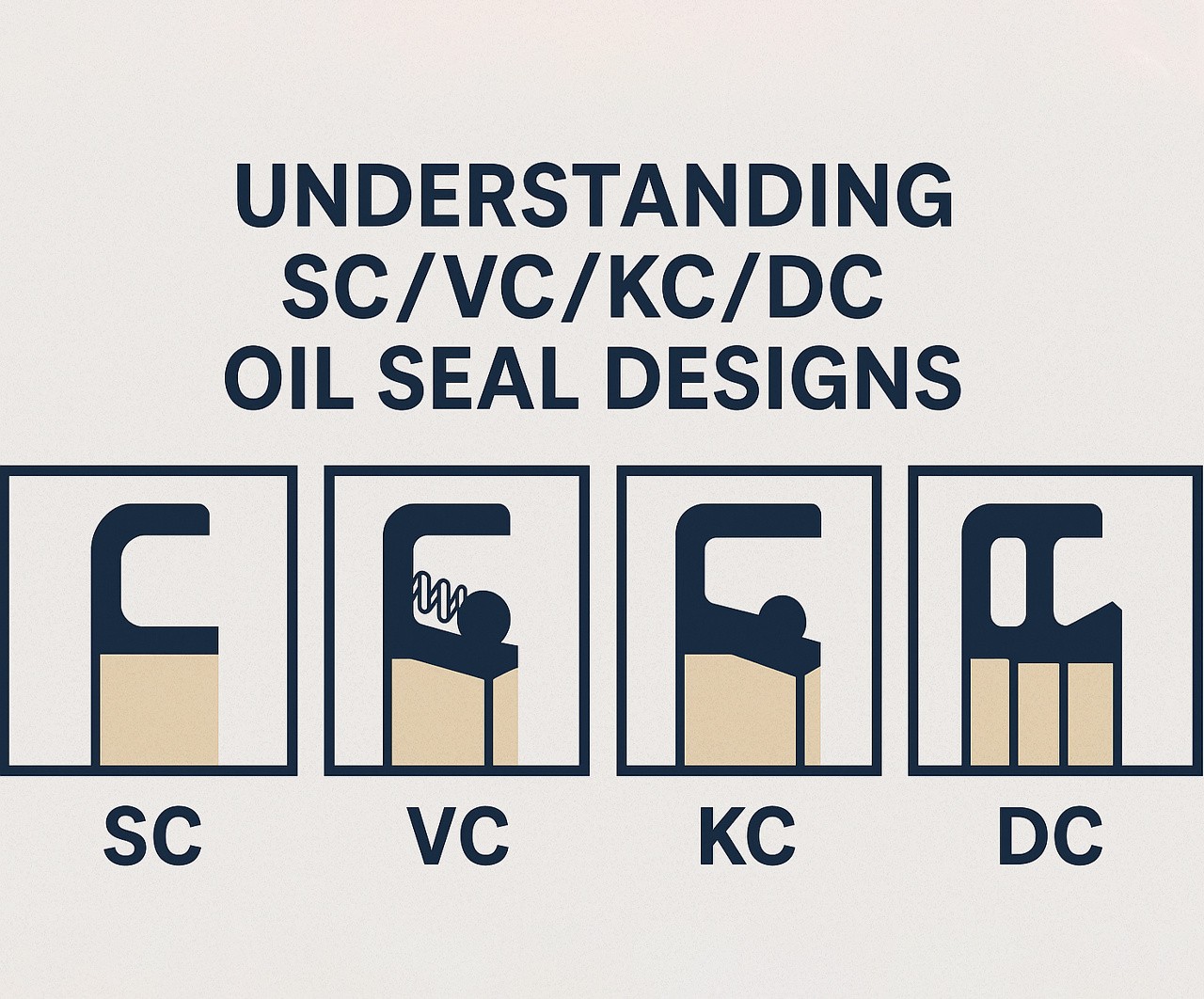

In high-speed rotating machinery and demanding automotive or industrial applications, proper sealing is crucial to prevent leaks, protect bearings, and extend component life. This is where SC, VC, KC, and DC oil seal designs come into play—each tailored for specific environments and performance levels. Whether you’re replacing an oil hub seal, upgrading an oil seal hub, or sourcing advanced oil seal rubber materials for your project, understanding these designations can make a huge difference in your equipment’s reliability and efficiency.

This article breaks down each oil seal type, how they differ, where to use them, and why selecting the right one is critical to achieving a leak-free, long-lasting seal. Know more..

What Are Oil Seals and Why Do They Matter?

Oil seals—also known as shaft seals, lip seals, or radial shaft seals—are essential in systems that contain lubricants while excluding contaminants. In rotating or reciprocating shafts, oil seals prevent the escape of oil and the intrusion of dust or moisture.

High-performance oil seal rubber, combined with robust metal casing and design geometry, ensures a tight seal even under challenging temperature, pressure, and speed conditions. The oil hub seal and oil seal hub are especially common in automotive wheels, gearboxes, and differentials, where they must endure high RPM, road contaminants, and heat.

SC Oil Seal Design – The Standard Workhorse

The SC (Single Lip with Metal Case) design is the most widely used configuration. It features:

- A single sealing lip

- A steel outer shell

- A garter spring for lip pressure

Best suited for:

- Moderate-speed shafts

- Light contamination environments

- General-purpose applications such as automotive axles, electric motors, and gearboxes

Oil hub seal systems with SC design offer a cost-effective sealing solution for standard duty use.

Advantages:

- Simple design

- Easy to install

- Economical

Limitations:

- Not ideal for dusty or high-contaminant environments

VC Oil Seal Design – The Dust Defender

VC seals add a dust lip to the SC design, making them double-lip oil seals. These are intended for dirty, abrasive conditions.

Structure:

- Primary oil sealing lip with spring

- Secondary dust exclusion lip

- Metal case or optional rubber-coated shell

Ideal for:

- Agricultural equipment

- Off-road vehicles

- Industrial motors with exposure to dust or splashes

When selecting an oil seal hub for trucks or ATVs, the VC configuration is often recommended to protect the primary lip from grit.

Advantages:

- Double protection

- Better contaminant resistance

- Longer service life in harsh environments

Limitations:

- Slightly more friction (due to second lip)

- More expensive than SC seals

KC Oil Seal Design – The Rubber-Coated Hybrid

KC seals combine the standard lip and spring setup with a full oil seal rubber coating over the outer diameter. This creates a more forgiving seal against imperfect housings or surfaces with corrosion or wear.

Use cases:

- Aluminum or soft metal housings

- Older equipment with worn bores

- Applications requiring a more forgiving fit

Features:

- Superior leak prevention

- Enhanced static sealing

- Lower risk of housing damage

Advantages:

- Excellent for retrofits

- Vibration absorption

- Compatible with press-fit or adhesive installation

Limitations:

- Lower pressure tolerance compared to metal-cased designs

KC seals often serve as replacements in difficult-to-fit oil hub seal applications in marine, power generation, and custom machinery.

DC Oil Seal Design – The Dual-Lip Pro

The DC configuration is a dual-lip seal with both lips under spring tension. It delivers top-tier sealing where internal pressure and external contamination are both high.

Applications:

- Hydraulic pumps

- Heavy-duty trucks

- High-RPM rotating assemblies

Construction:

- Twin sealing lips

- Dual springs (optional)

- Reinforced steel insert

When a standard oil seal hub can’t hold up to the pressure, DC designs offer the robust sealing needed in performance-critical systems.

Advantages:

- Handles high loads

- Superior sealing under pressure swings

- Improved oil retention and contaminant exclusion

Limitations:

- Requires precise installation

- Higher cost

Choosing the Right Oil Seal Rubber Material

The lip material determines chemical resistance, temperature range, and friction characteristics. Common options include:

| Material | Temp Range | Best For |

| Nitrile (NBR) | -40°C to 120°C | Water, oils, general use |

| Viton (FKM) | -25°C to 200°C | High-temp, fuel, synthetic oils |

| Silicone | -60°C to 180°C | Extreme cold, food-grade applications |

| Polyacrylate | -30°C to 150°C | Automotive transmissions |

Oil seal rubber selection is just as important as choosing the right design. A VC seal with low-grade rubber will underperform in a hot engine compartment.

Compatibility Chart – Quick Reference

| Application | Recommended Seal | Reason |

| Automotive wheel hub | VC | Dust resistance for road conditions |

| High-temp pump | KC with Viton | Heat and pressure tolerance |

| Electric motor | SC | Clean, controlled environment |

| Tractor PTO shaft | DC | Handles heavy load and grease/dirt |

| Retrofit housing | KC | Compensates for worn bores |

Installation Tips

To get the most from your oil hub seal, follow these steps:

- Inspect the shaft and housing: Look for nicks, scratches, and concentricity.

- Use proper tools: Don’t hammer seals—use a seal driver or press.

- Lubricate: Lightly coat the sealing lips with compatible grease.

- Align carefully: Avoid cocking the seal during installation.

- Don’t reuse: A reused seal often fails prematurely.

Even the best oil seal hub won’t perform if installed incorrectly.

Failure Modes to Watch For

- Lip hardening: Excessive heat or incompatible fluids

- Spring pop-out: High-speed or misaligned shaft

- Cracking rubber: Low-quality oil seal rubber or UV exposure

- Seal spin-out: Poor fit or incorrect housing surface finish

Regular inspection and timely replacement can save major repair costs.

Innovations in Oil Seal Design

The sealing industry is evolving. Look for these advanced features in SC/VC/KC/DC oil seals:

- Low-friction PTFE lips for reduced energy loss

- Directional hydrodynamic grooves to pump oil inward

- Composite metal-rubber casings for better adaptability

- Sensor-integrated seals for RPM or pressure feedback

As electric vehicles and smart machines become more common, seal designs will continue to evolve.

Final Thoughts

Choosing the right oil seal is about more than matching dimensions. It’s about understanding the duty cycle, environmental challenges, and fluid compatibility. Whether you’re maintaining a fleet, repairing gearboxes, or sourcing OEM replacements, knowing when to use SC, VC, KC, or DC seal designs gives you an edge in performance and reliability.

The oil hub seal, oil seal hub, and oil seal rubber you choose could determine whether your system runs for years—or breaks down in weeks.

For high-performance applications, always consult a seal engineer or trusted manufacturer. They’ll help you match not just the type—but the right material, size, and installation method for your sealing challenge.

Seal it right. Seal it once. And move forward with confidence.