Built for Heat, Designed for Precision | High Temperature Resistance 80 Shore O Ring Rubber Seals

The High Temperature Resistance 80 Shore O Ring Rubber Seals are specifically engineered for high-performance sealing in extreme thermal and chemical environments. Ideal for use in industrial equipment, thermal systems, and chemical processing machinery, these O-rings maintain their sealing strength even under prolonged exposure to elevated temperatures and corrosive media. Manufactured with high-grade elastomers such as FKM, silicone, and EPDM, they provide superior resistance to compression set, thermal degradation, and aggressive fluids—ensuring long-term operational efficiency and leak-free reliability.

These O-ring rubber seals are designed with a balanced 80 Shore hardness, offering both flexibility and structural integrity for high-pressure static or dynamic applications. Whether used in gaskets, flanges, or spacer components, their precise molding and high-temperature resistance make them suitable for demanding sectors such as aerospace, automotive, energy, and industrial processing. With exceptional dimensional stability and a wide service temperature range, these seals help minimize maintenance cycles and protect equipment from costly wear, leaks, and performance loss.

Product Specifications

| Attribute | Details |

|---|---|

| Product Name | High Temperature Resistance 80 Shore O Ring Rubber Seals |

| Material Type | Rubber |

| Type | High Performance O-Ring Seals |

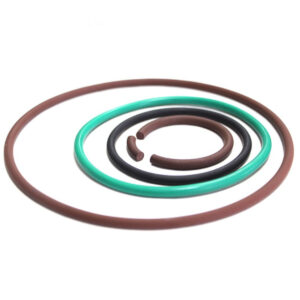

| Color | Black, Brown, Green |

| Hardness | 75/80/90 Shore A |

| Feature | Chemical & Oil & High Temperature Resistance |

| Temperature | -20℃ to +260℃ |

Why Choose High Temperature Resistance 80 Shore O Ring Rubber Seals?

🔹 Rated 80 Shore A for optimal hardness and flexibility balance

🔹 Reliable performance in environments up to 320°C

🔹 Resistant to oils, chemicals, solvents, and high heat

🔹 Made with premium elastomers like FKM and silicone

🔹 Suitable for both static and dynamic sealing applications

🔹 Easy to fit in grooves, flanges, and confined sealing spaces

🔹 Minimizes maintenance cycles and operational downtime

🔹 Offers consistent sealing even under thermal cycling

🔹 Designed for long-term durability in harsh industrial settings

🔹 Supports tight tolerances for precision sealing

Application of High Temperature Resistance 80 Shore O Ring Rubber Seals

🔹 Thermal Systems – Used in high-temperature heating, ventilation, and furnace equipment

🔹 Chemical Plants – Effective in sealing pipes, joints, and pumps handling aggressive chemicals

🔹 Food & Beverage Industry – Ideal for high-temperature sanitization and fluid systems

🔹 Oil & Gas Equipment – Ensures leak-proof seals in exploration and refinery machinery

🔹 Power Generation – Applied in turbines, heat exchangers, and high-pressure vessels

🔹 Automotive & Aerospace – Seals engine parts and systems exposed to heat and vibration

Order Now – Get Your High Temperature Resistance 80 Shore O Ring Rubber Seals Today!

Upgrade your system’s thermal sealing reliability with High Temperature Resistance 80 Shore O Ring Rubber Seals. Crafted for high-heat endurance and tested under extreme operating conditions, these O-rings provide the strength and adaptability needed for sealing performance in critical applications. From energy production to chemical handling, trust these precision-engineered rubber seals to keep your systems secure, efficient, and maintenance-friendly. Choose long-lasting sealing that performs when it matters most.

Designed for both commercial and industrial environments, these high-performance O-rings are an essential solution for engineers and maintenance professionals dealing with extreme temperatures and fluid exposure. Their robust material composition resists hardening, cracking, and breakdown over time, making them ideal for long-duration installations where replacement is costly or impractical. With versatile compatibility across equipment and easy integration into sealing grooves, these rubber seals offer unmatched reliability where other materials fall short.