When sourcing components for hydraulic systems, choosing the right supplier is just as crucial as selecting quality parts. Whether you’re maintaining heavy equipment or managing a production line, the performance of hydraulic cylinder piston seals, hydraulic gear pump seals, and hydraulic jack pump seal products can make or break your operation. If you’re serious about securing a reliable, long-term supplier relationship, it’s time to look beyond just pricing sheets and lead times.

This guide will explore what qualities define a trustworthy hydraulic seal supplier, what questions to ask, and how to assess their long-term value to your business. Know more..

Why Supplier Choice Matters More Than Ever

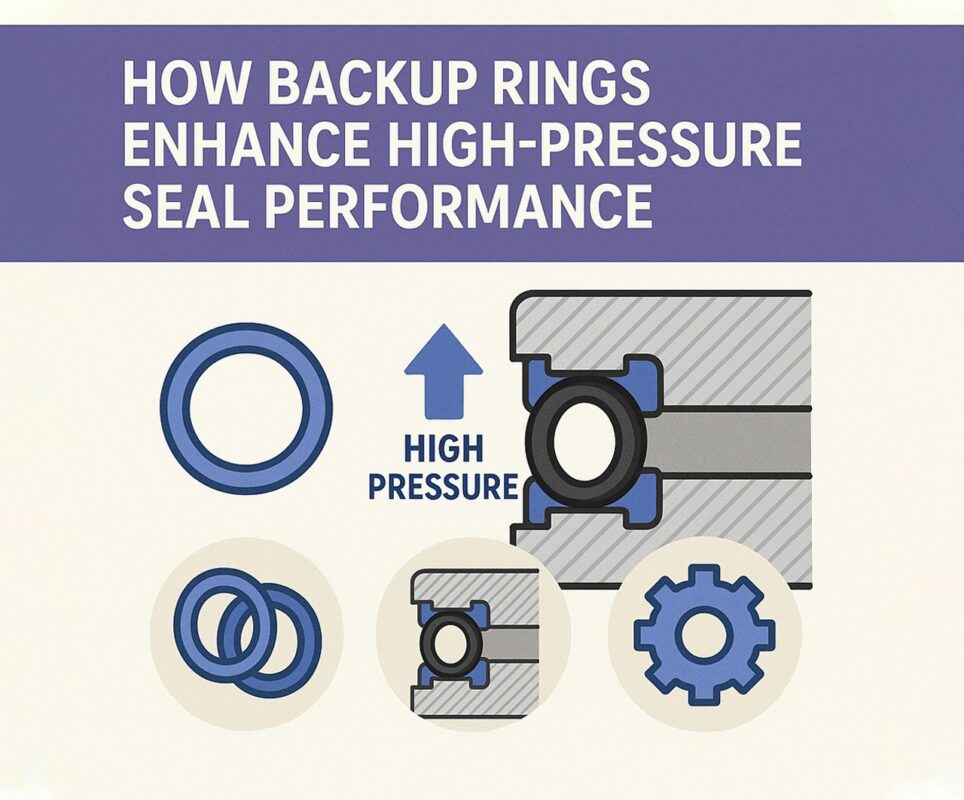

Today’s industries demand faster turnarounds, zero-downtime maintenance schedules, and components that perform under intense conditions. Hydraulic cylinder piston seals, hydraulic gear pump seals, and hydraulic jack pump seal units are not off-the-shelf accessories—they’re high-precision components that affect everything from leak prevention to system efficiency.

A weak link in your supply chain can lead to production delays, costly downtime, and equipment failures. Partnering with a reliable supplier ensures product consistency, technical support, and competitive pricing over the long haul.

What to Look for in a Hydraulic Seal Supplier

1. Product Range and Specialization

Your ideal supplier should stock a comprehensive range of seals, including standard and custom options for hydraulic cylinder piston seals, hydraulic gear pump seals, and hydraulic jack pump seal assemblies.

Specialized suppliers who understand the unique demands of different applications can recommend the right material grades (like Viton, NBR, or PTFE), pressure ratings, and temperature tolerances for your operating conditions.

2. Quality Control and Certifications

Look for suppliers with ISO certifications or documented quality control processes. A company supplying hydraulic cylinder piston seals should provide traceability and documentation for material batches, testing protocols, and compliance with international standards.

Ask about in-house inspection tools, from hardness testers to dimensional gauges. This ensures every hydraulic gear pump seals order you receive meets consistent quality benchmarks.

Signs of a Long-Term Partner vs. a One-Time Vendor

Long-term suppliers:

- Proactively suggest better solutions for recurring issues.

- Keep you informed about new materials or technologies.

- Offer flexible inventory programs.

- Provide engineering support for custom projects.

One-time vendors:

- Focus only on transactional sales.

- Lack technical expertise for your applications.

- Offer limited product ranges.

- Provide slow, impersonal customer service.

When sourcing hydraulic jack pump seal replacements or upgrades, work with a company that behaves like a partner, not just a middleman.

Evaluate Lead Times and Stock Availability

Hydraulic systems can’t afford weeks-long delays for critical parts. Your supplier should:

- Keep regular stock of high-demand components like hydraulic cylinder piston seals.

- Offer expedited delivery options.

- Provide realistic, transparent lead times for custom or bulk orders.

Ideally, suppliers should carry stock levels that reflect your industry’s demands and offer reserved inventory programs for recurring customers.

Technical Knowledge and Support

In hydraulic sealing, details matter. Partner with suppliers who:

- Can explain the differences between high-pressure and low-pressure hydraulic gear pump seals.

- Offer recommendations for seal profile types.

- Understand material compatibility with different hydraulic fluids.

- Provide advice on installation and storage best practices.

Bonus points for suppliers offering CAD drawings, spec sheets, and technical articles specific to hydraulic jack pump seal and other components.

Innovation and Product Development

A long-term partner should stay ahead of the market. Are they introducing advanced materials? Developing proprietary seal designs? Integrating IoT or wear-sensing technology for critical hydraulic cylinder piston seals?

Suppliers who lead in innovation help future-proof your systems. They should proactively introduce new solutions for common problems like heat resistance, extrusion damage, or chemical attack in hydraulic gear pump seals.

Customization Capabilities

Custom seal solutions are often necessary for aging equipment or non-standard cylinders. A good supplier should offer:

- Rapid prototyping

- Custom machining

- On-demand hydraulic jack pump seal configurations

- Small-batch production runs

If your supplier lacks this flexibility, you may be forced into costly equipment upgrades or downtime.

Pricing Transparency and Value

While price is always a factor, don’t base your decision on unit cost alone. Evaluate:

- Value-added services (engineering support, inventory programs)

- Delivery guarantees

- Warranty coverage

- Return policies

When pricing hydraulic cylinder piston seals, consider the total lifecycle cost—including potential downtime, installation time, and performance longevity.

Supplier Reputation and Reviews

Word-of-mouth matters. Research reviews from industries similar to yours. Look for recurring themes around:

- Product quality

- On-time delivery

- Customer service responsiveness

- Long-term reliability

A supplier praised for their hydraulic gear pump seals by one heavy-equipment fleet is likely worth considering for your operation too.

Inventory Management and Logistics Support

Supply chain delays can cripple hydraulic operations. Evaluate how well your supplier manages their logistics:

- Do they offer consignment inventory programs?

- Can they provide predictive ordering based on your historical usage of hydraulic jack pump seal products?

- Are they transparent about lead times?

The right supplier will have systems in place to avoid stockouts and proactively communicate delays.

Sustainability and Environmental Practices

Sustainability is gaining traction even in industrial sectors. Ask about your supplier’s environmental policies:

- Are seal materials recyclable?

- Do they offer eco-friendly packaging?

- What’s their waste-reduction strategy?

A forward-thinking supplier of hydraulic cylinder piston seals should care about environmental impact while maintaining performance standards.

After-Sales Service and Warranty Coverage

Even premium seals can fail under extreme conditions. Partner with suppliers who offer:

- Clear warranty terms for hydraulic gear pump seals and other products.

- Quick-turn replacements.

- Technical troubleshooting support.

- Failure analysis reporting.

After-sales service reflects a supplier’s confidence in their products and commitment to customer satisfaction.

How to Vet Potential Suppliers: 5 Smart Steps

- Request a Product Sample Test their hydraulic jack pump seal or hydraulic gear pump seals before placing a large order.

- Visit Their Facility If possible, tour their warehouse or production floor.

- Review Their Certifications Check ISO, REACH, RoHS, and industry-specific credentials.

- Conduct a Trial Order Start small and evaluate fulfillment speed, product accuracy, and communication.

- Check Industry References Ask for referrals from companies using similar hydraulic systems.

Final Thoughts: Build a Partnership, Not Just a Vendor List

The best suppliers for hydraulic cylinder piston seals, hydraulic gear pump seals, and hydraulic jack pump seal components do more than move boxes—they deliver solutions, insights, and peace of mind. They act as an extension of your maintenance and engineering teams, invested in your long-term operational success.

As you evaluate potential suppliers, prioritize those who combine product expertise with reliable logistics, technical support, and future-ready innovation. In today’s competitive industrial landscape, your seals should work as hard and smart as your business does.