In critical applications like pumps, compressors, and rotating equipment, the performance of sealing components often determines system efficiency and lifespan. Choosing the right materials isn’t guesswork—it’s a science backed by precise testing. When it comes to high-performance seals like a carbide seal, graphite Seals packing rings, and silicon carbide shaft seal, proper material testing ensures durability under intense pressure, temperature fluctuations, and chemical exposure. Whether you’re manufacturing for industrial, aerospace, or petrochemical environments, rigorous material validation is non-negotiable.

In this comprehensive guide, we’ll explore why material testing matters, the methods used, and what smart buyers and engineers should demand before signing off on custom seal solutions. Know more..

Why Material Testing Is Critical for Carbide and Graphite Seals

Sealing components face extreme conditions, including high rotational speeds, corrosive chemicals, and fluctuating pressures. A carbide seal or silicon carbide shaft seal that hasn’t been adequately tested for hardness, wear resistance, and chemical compatibility is a liability.

Similarly, graphite packing rings need to maintain integrity under high-temperature and high-pressure conditions while resisting chemical degradation. Subtle flaws in the material can cause premature failure, leaks, and catastrophic system breakdowns.

Material testing ensures each batch of seal materials meets industry, OEM, and safety standards—before installation.

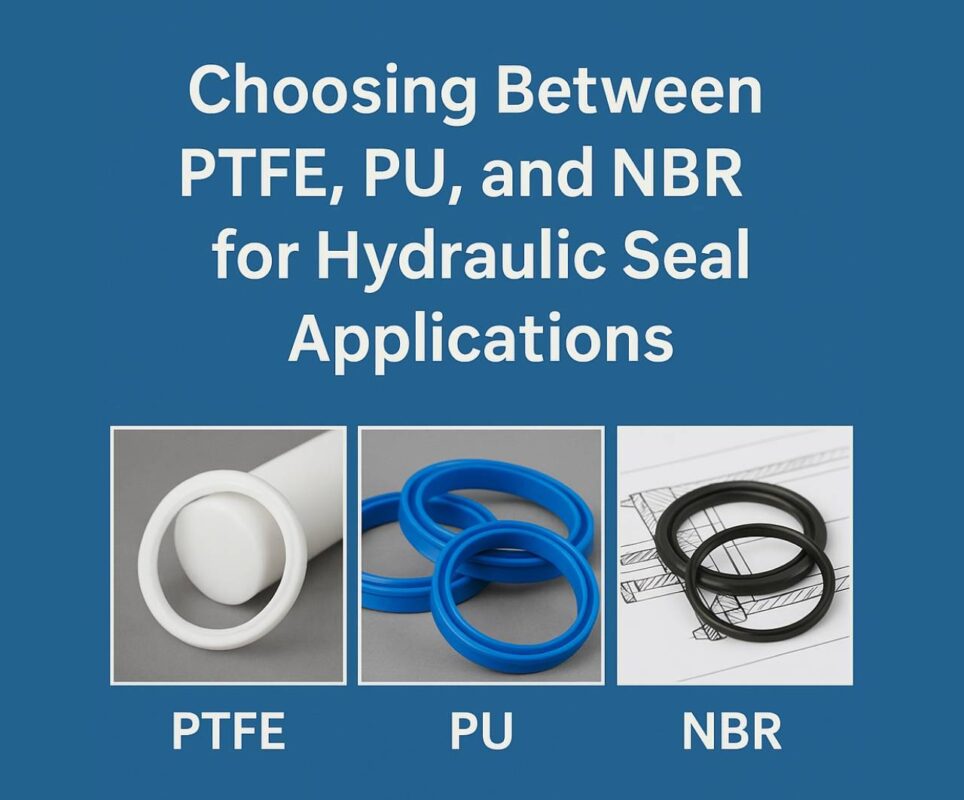

Popular Materials Used in Custom Seal Applications

Carbide seal solutions are typically made from:

- Tungsten carbide: Known for hardness and wear resistance.

- Silicon carbide: Lightweight, corrosion-resistant, and ideal for aggressive chemicals.

- Graphite packing rings are manufactured from:

- Pure graphite

- Reinforced graphite composites

- Flexible graphite with metallic inserts

- Silicon carbide shaft seal components are prized for:

- High mechanical strength

- Thermal conductivity

- Exceptional resistance to corrosive environments

Each material must be tested to confirm its suitability for the intended operational environment.

Key Tests Performed on Carbide and Graphite Seal Materials

1. Hardness Testing

Essential for both carbide seal and silicon carbide shaft seal components. Measured using Rockwell, Vickers, or Mohs scales. High hardness correlates with wear resistance in abrasive applications.

2. Density and Porosity Testing

Density impacts strength and heat transfer. Porosity tests identify hidden voids in graphite packing rings and carbide materials that can weaken seals under stress.

3. Flexural and Compressive Strength

Custom seals, especially silicon carbide shaft seal units, undergo flexural testing to confirm their ability to withstand bending forces during installation and operation.

4. Thermal Shock Resistance

This test checks how materials like graphite packing rings and carbide seal components react to rapid temperature changes—a common hazard in industrial operations.

5. Chemical Compatibility Testing

Materials are submerged in chemicals they’ll encounter in service, from acids to oils. Performance changes in a silicon carbide shaft seal or graphite packing rings are noted.

6. Friction and Wear Testing

Simulated operational conditions evaluate the wear rate and friction coefficient of carbide seal and graphite packing rings materials under rotating and reciprocating motion.

Advanced Testing Techniques for Custom Applications

Microstructural Analysis

Used for both carbide seal and silicon carbide shaft seal parts, this involves microscopic examination of material grain structure and defects.

Ultrasonic and X-ray Inspections

Detect internal flaws and porosity in carbide and composite materials without destructive testing.

High-Temperature Creep Testing

Particularly for graphite packing rings exposed to constant heat, measuring material deformation over time.

New Ideas: Integrating Predictive Modeling with Testing

Modern material testing isn’t limited to physical samples. Leading manufacturers now use digital simulation tools alongside traditional tests. These models predict how a silicon carbide shaft seal or carbide seal will behave in extreme environments, refining product designs before prototyping.

By simulating wear patterns, thermal expansion, and chemical attack virtually, engineers can optimize material blends and geometries to improve real-world performance.

Material Testing Standards You Should Demand

When ordering custom graphite packing rings, carbide seal, or silicon carbide shaft seal components, confirm that suppliers follow internationally recognized standards like:

- ASTM (American Society for Testing and Materials)

- ISO (International Organization for Standardization)

- ASME (American Society of Mechanical Engineers)

- API (American Petroleum Institute for oil and gas applications)

Ask suppliers to provide certifications and test reports specific to your application.

How to Vet a Seal Supplier’s Testing Capabilities

- Request a testing equipment list

- Verify third-party or in-house lab credentials

- Review sample test certificates for previous orders

- Ensure they offer application-specific testing (chemical, thermal, mechanical)

- **Confirm they conduct batch testing for large-volume orders of graphite packing rings and carbide seal sets

A supplier invested in proper testing demonstrates long-term reliability and reduced operational risk.

The Cost of Skipping Proper Testing

Poorly tested seals result in:

- Costly downtime

- Frequent maintenance and replacements

- Equipment damage

- Loss of product containment (hazardous leaks)

- Legal and regulatory violations

An inadequately tested silicon carbide shaft seal or graphite packing rings batch can multiply costs in critical infrastructure, chemical plants, and refineries.

Sustainability Benefits of Tested, High-Quality Seals

By investing in better-tested carbide seal and graphite packing rings, operators reduce waste generated from frequent seal replacements. Longer-lasting, efficient seals lower energy consumption in pumps and compressors and minimize fluid leaks.

In industries under increasing environmental scrutiny, reliable silicon carbide shaft seal materials also reduce the risk of environmental contamination.

Best Practices for End-User Seal Testing

While manufacturers perform rigorous tests, end-users should also:

- Perform visual inspections on arrival

- Measure dimensions against order specs

- Conduct pressure leak tests during commissioning

Documented acceptance testing adds another layer of quality assurance for carbide seal and graphite packing rings installations.

Emerging Materials to Watch

Innovation continues in this field, with materials like:

- Carbon fiber-reinforced graphite packing rings for aerospace

- Diamond-like carbon (DLC)-coated silicon carbide shaft seal components for medical devices

- Nano-composite carbide seal materials for ultra-high-pressure pumps

Keep an eye on emerging materials offering improved performance with lighter weights and lower environmental impact.

Final Thoughts

Material testing isn’t just a checkbox on a manufacturing spec sheet—it’s the foundation for safe, efficient, and sustainable operations. Whether you need carbide seal solutions for harsh chemical mixers, graphite packing rings for steam valves, or a silicon carbide shaft seal for a refinery pump, demanding comprehensive, standardized testing reduces risk and extends equipment life.

Partner with suppliers who prioritize both physical and predictive testing, stay current with evolving ASTM and ISO standards, and deliver data-backed performance assurances. In the world of industrial sealing, the most reliable systems start with the smartest material testing.