In commercial vehicles, durability and performance aren’t just expectations—they’re requirements. Nowhere is this more evident than in the power steering system, where hydraulic force and high pressure come into play daily. A reliable single coil mechanical seal, a responsive single coil spring seal, and a precision-fitted submersible pump oil seal are all essential components in ensuring that power steering units function without leakage or breakdown. These sealing solutions form the backbone of power-assisted steering in everything from long-haul trucks to delivery vans.

In this article, we’ll explore the role of power steering oil seals in commercial vehicles, how they differ from seals in other systems, and why innovations like the single coil spring seal and submersible pump oil seal are shaping the future of heavy-duty steering systems. Know more..

Why Oil Seals Matter in Power Steering Systems

Power steering systems rely on pressurized hydraulic fluid to reduce the steering effort required by the driver. Oil seals prevent this fluid from leaking at key junctions, such as the steering gear input shaft, rack ends, or power steering pump output shaft. Without proper sealing:

- Hydraulic pressure is lost

- Steering becomes sluggish or unresponsive

- Systems become prone to contamination and wear

The right oil seal ensures consistent performance, lower maintenance costs, and extended service life for the steering system.

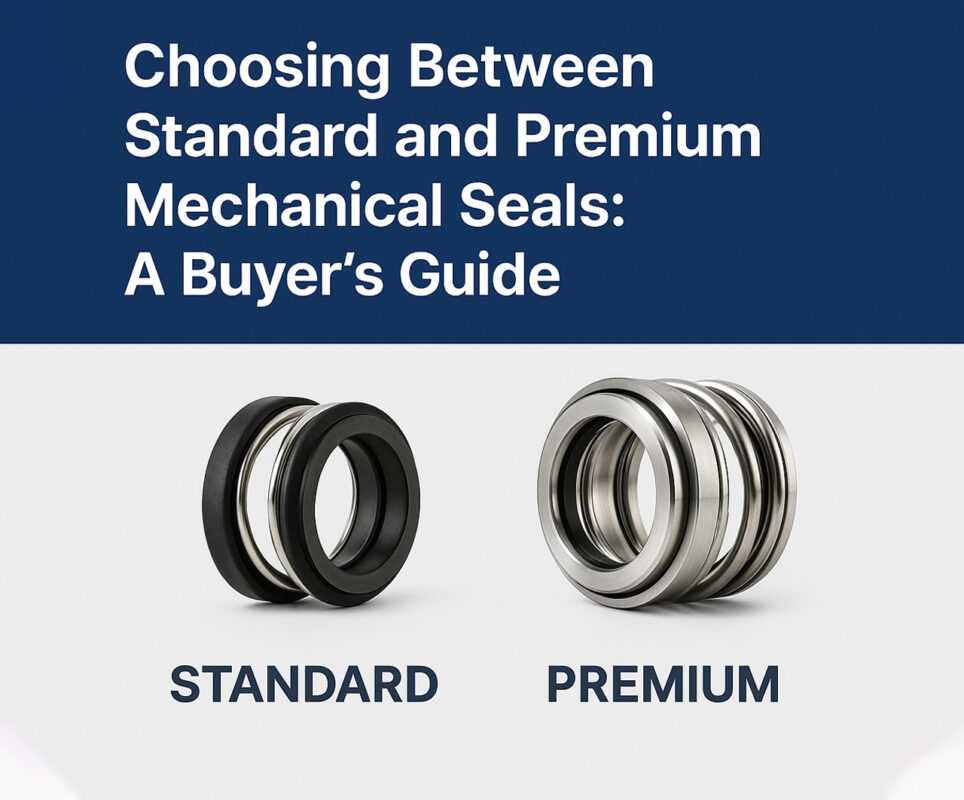

Understanding the Single Coil Mechanical Seal in Steering Pumps

The single coil mechanical seal is often used in steering pumps for its ability to maintain face contact even under variable pressure. Unlike multiple spring seals, it uses one continuous coil spring to provide uniform pressure across the seal faces.

Advantages of Single Coil Mechanical Seals:

- Fewer parts = reduced risk of failure

- Simple design allows for easy replacement

- Maintains reliable sealing in dynamic environments

In power steering systems, they are frequently installed in gear-driven hydraulic pumps or belt-driven steering pumps that operate at moderate to high RPMs.

How Single Coil Spring Seals Enhance Durability

The single coil spring seal is a specific type of mechanical seal that uses a tightly wound spring to apply consistent pressure on the sealing faces. In commercial vehicle steering systems, this means:

- Better vibration resistance

- Stable sealing despite rapid directional changes

- Enhanced protection against pressure spikes

The benefit of a single coil spring seal over a wave spring or multi-spring design is its tolerance to misalignment and shock—both common in heavy-duty applications.

The Role of Submersible Pump Oil Seals in Fluid Management

Though more often associated with vertical fluid handling systems, the submersible pump oil seal has found its way into steering reservoirs and pump housings in commercial vehicles. Its advantages include:

- Superior sealing under immersion

- Resistance to water and oil blend environments

- Long service intervals under harsh operating conditions

Power steering systems with integrated cooling or fluid reservoirs benefit from submersible pump oil seals that can maintain sealing even when submerged or partially flooded.

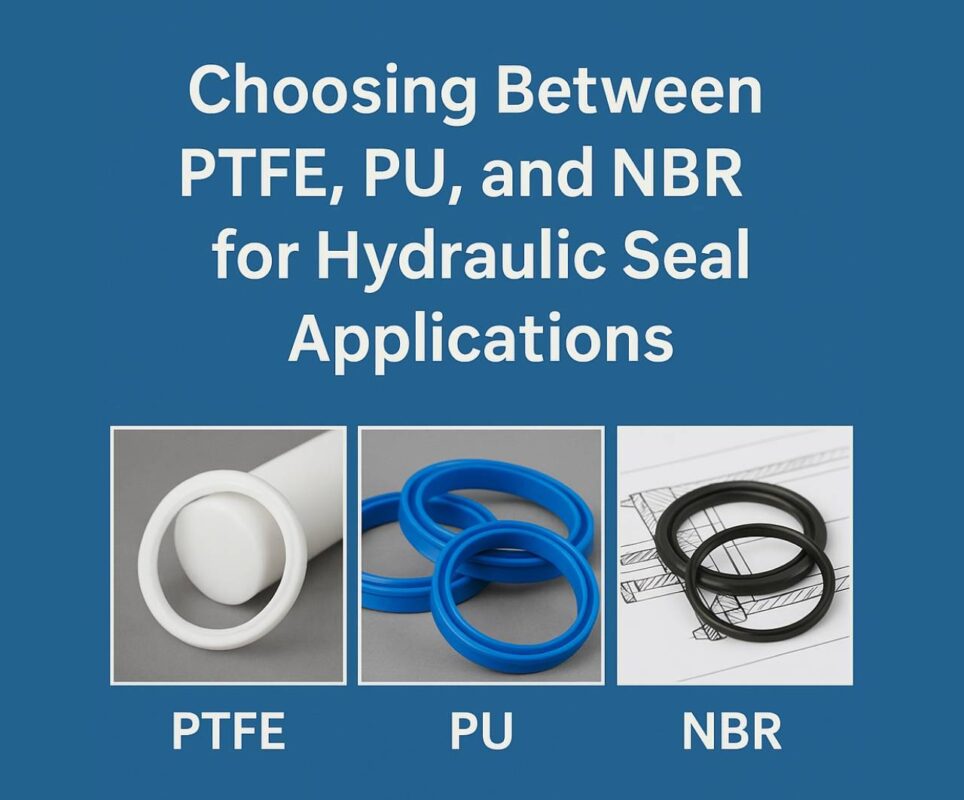

Material Selection for Power Steering Oil Seals

Seal performance isn’t just about design—it’s also about material. Common choices include:

- Nitrile (NBR): Affordable and oil-resistant; standard for many commercial vehicles

- Viton (FKM): Withstands high temperatures and aggressive fluids

- EPDM: Excellent resistance to water-based coolants, but less suitable for oils

For a single coil mechanical seal or single coil spring seal, pairing carbon or ceramic faces with Viton elastomers provides long-lasting reliability.

How Seals Handle Steering Fluid Pressure and Heat

Power steering fluid is under continuous pressure, sometimes spiking during hard turns or prolonged idling. Seals need to resist:

- Pressure up to 1500 psi (in some systems)

- Temperatures from -40°C to 120°C

- Chemical breakdown from ATF or hydraulic oil additives

Seals with a submersible pump oil seal profile can handle these extremes while resisting fluid absorption or swelling.

Installation Considerations for Power Steering Seals

- Surface Finish: The shaft must be smooth and clean to prevent tearing the seal lip.

- Correct Orientation: Installing a single coil spring seal backwards defeats its pressure-holding capabilities.

- Use of Lubricants: Apply appropriate grease to the sealing lip during installation.

- Avoid Over-Compression: Over-tightening the housing can distort the seal.

Always inspect old seals for wear patterns—these can indicate alignment issues or excessive shaft movement.

Troubleshooting Power Steering Leaks

Leaks in power steering systems may stem from:

- Worn single coil mechanical seal faces

- Hardened or cracked elastomers

- Incorrect seal size or installation

- Shaft grooving due to corrosion or vibration

If the issue persists, upgrading to a higher-grade material or switching to a submersible pump oil seal configuration may offer better longevity.

Real-World Example: Fleet Vehicle Maintenance

A delivery fleet servicing 200+ box trucks experienced repeated power steering failures. Investigation revealed worn single coil spring seals in their steering pumps, exacerbated by poor cooling and inconsistent fluid quality.

Solution:

- Switched to Viton-based single coil mechanical seals

- Upgraded reservoir units to include submersible pump oil seals for longer fluid retention

Results:

- Downtime dropped by 40%

- Annual steering-related maintenance costs reduced by $35,000

- Seal replacement cycle extended from 18 months to 3+ years

Future Trends in Power Steering Seal Technology

- Integrated sensors: Detect early seal wear via temperature and pressure change

- Low-friction coatings: Reduce drag on the shaft and increase fuel efficiency

- Hydrogen and EV compatibility: Seals for electric and alternative fuel systems must resist different fluid chemistries

The evolution of the single coil spring seal and submersible pump oil seal technologies is already pushing into electric power-assisted steering (EPAS) systems.

Inventory Recommendations for Wholesalers

For wholesalers or fleet maintenance buyers, essential SKUs include:

- Single coil mechanical seal in shaft sizes from 12mm to 25mm

- Single coil spring seal repair kits

- Submersible pump oil seal options with NBR and Viton variants

Bundling these seals with O-ring kits and hydraulic fluid seals ensures fast turnarounds and customer satisfaction.

Final Thoughts

Power steering oil seals play a vital role in commercial vehicle performance. From the humble single coil mechanical seal to the robust submersible pump oil seal, these components keep fluid systems tight, safe, and efficient. In an industry where uptime is profit, investing in the right seal design and material pays off with every turn of the wheel.

Stay proactive. Stock smart. And steer your fleet toward better performance with reliable sealing solutions.