When discussing two-wheeler performance and maintenance, one crucial yet often overlooked component is the oil seal. These compact yet critical parts are vital for keeping engines, gearboxes, and suspension systems leak-free and efficient. Interestingly, many motorcycle users who search for specific seal types may also cross-reference terms used in industrial settings, such as boiler feed water pump mechanical seal, hot oil pump mechanical seal, and mechanical Best oil seals types. While these keywords may originate from larger-scale machinery, the underlying principles of heat resistance, pressure management, and material compatibility are just as relevant to motorcycles.

In this comprehensive guide, we explore the best oil seals for motorcycles, how they relate to industrial-grade sealing technology, and how to choose the right product for high-performance two-wheeler applications. Know more..

Understanding the Role of Oil Seals in Motorcycles

Motorcycles, especially performance or long-distance touring models, operate under high heat and mechanical stress. Oil seals in this environment:

- Prevent leakage of engine or transmission oil

- Protect against dust, dirt, and water ingress

- Maintain internal pressure differentials

From crankshafts to forks, a quality oil seal ensures mechanical integrity. This makes selecting the proper mechanical oil seal types crucial.

Mechanical Oil Seal Types in Motorcycle Engineering

Although motorcycles are smaller than boilers or process pumps, many mechanical oil seal types are borrowed or adapted from industrial technology:

- Rotary Shaft Seals: Common in crankshafts and camshafts

- Fork Seals: Specialized to retain oil in telescopic front suspension

- Countershaft Seals: Used in transmission output shafts

- Valve Stem Seals: Control oil entry into combustion chambers

Like a boiler feed water pump mechanical seal, these components must endure heat, vibration, and pressure. Therefore, seal geometry and materials are mission-critical.

What Makes a Great Motorcycle Oil Seal?

The best seals for motorcycles share three key characteristics:

- Heat Resistance: Especially important for high-revving engines or bikes that idle in hot weather.

- Chemical Compatibility: Must tolerate synthetic oils, fuel mist, and cleaning agents.

- Long-Term Elasticity: High-quality elastomers like Viton or NBR ensure durability over time.

Borrowing from hot oil pump mechanical seal technology, the ideal seal must withstand continuous high-temperature oil circulation without swelling or cracking.

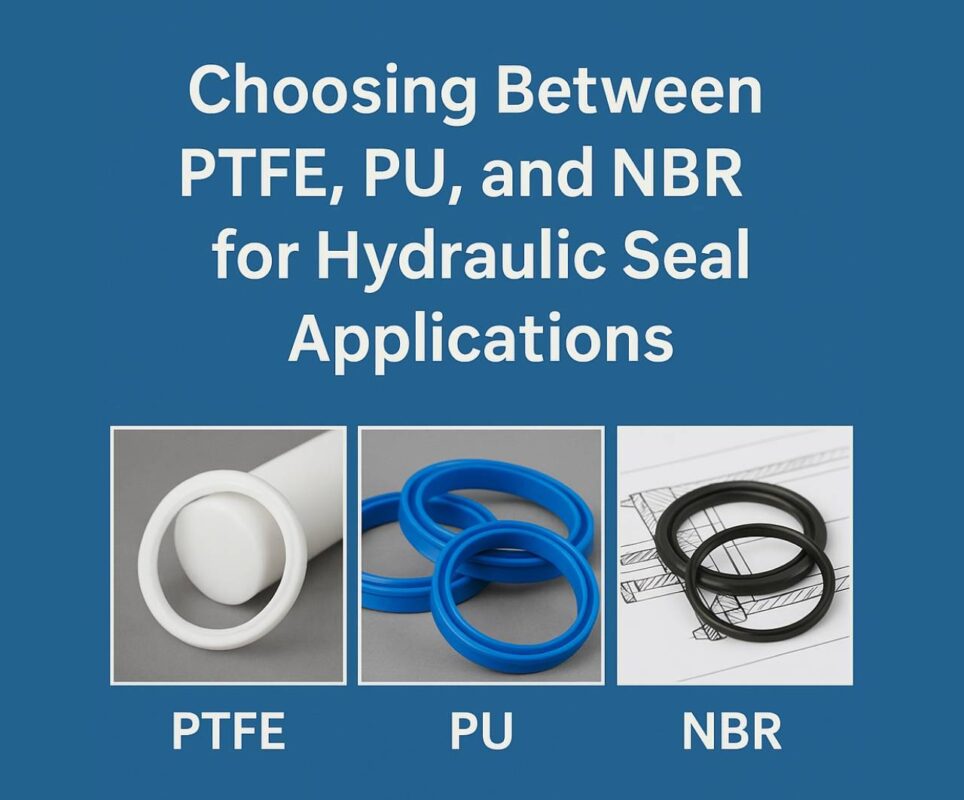

Material Matters: Choosing the Right Elastomer

| Material | Ideal For | Notes |

| Nitrile (NBR) | General-use motorcycles | Good for mild temperatures |

| Viton (FKM) | High-performance or racing | Excellent chemical and thermal resistance |

| Silicone | Cold weather riding | Remains flexible in freezing conditions |

| Polyacrylate | Transmission systems | Strong resistance to hot oil exposure |

For extreme-duty motorcycles—off-road, racing, or adventure—the hot oil pump mechanical seal materials and specs are highly relevant.

Fork Seals: Your Frontline Suspension Defender

Motorcycle fork seals are notorious for failing if made from substandard materials. They must:

- Withstand dynamic movement

- Block mud, dust, and moisture

- Maintain tight oil retention

Many riders who prioritize durability look for fork seals derived from mechanical oil seal types designed for reciprocating shafts—like those used in hydraulic presses or piston rods.

Gearbox and Countershaft Oil Seals

The gearbox in motorcycles contains complex moving parts, and its seals are often subjected to hot, pressurized oil—just like a boiler feed water pump mechanical seal in a high-pressure pump. These seals must be:

- High-precision fit

- Reinforced with steel cases

- Resistant to shaft misalignment

Failure here leads to oil leaks that can damage the chain or cause slipping, endangering both bike and rider.

Rear Wheel and Hub Seals

Though less exposed to heat, these seals protect the wheel bearings and hub from water, dust, and mud. Off-road motorcycles especially require:

- Dual-lip or triple-lip designs

- Labyrinth seal enhancements

- Dirt-shedding external profiles

These design choices reflect strategies used in hot oil pump mechanical seal configurations for rugged environments.

How to Identify Seal Wear

Watch for the following symptoms:

- Visible oil leakage near engine covers or forks

- Grease on the rear wheel or brake disc

- Increased engine heat due to oil depletion

- Sloppy or inconsistent suspension response

Early identification and replacement of faulty seals prevent bigger mechanical failures.

Installing Oil Seals: Best Practices

- Clean the Area Thoroughly: Dirt and grime destroy sealing surfaces.

- Use Seal Drivers: Prevent lip damage and ensure flush fitment.

- Lubricate Before Install: Use light oil to ease insertion and prevent startup friction.

- Double-Check Orientation: Installing backwards ruins the sealing effect.

Motorcycle seals are typically easier to install than a boiler feed water pump mechanical seal, but precision still matters.

Top Brands Making Motorcycle-Grade Seals

Some of the best seal manufacturers offer motorcycle-specific lines:

- SKF: Known for their fork seal kits

- NOK: OEM for many Japanese motorcycles

- Corteco/Freudenberg: Often used in European bikes

- Koyo: Durable and accessible for most bikes

Their industrial legacy with mechanical oil seal types adds credibility to their motorcycle offerings.

Case Study: High-Heat Commuter Bike in Urban Traffic

A delivery rider in a congested city noticed frequent oil leaks from his 150cc bike’s crankshaft. After inspection, the mechanic noted heat damage to the seals due to extended idling and heavy stop-and-go traffic.

Solution: Upgraded to Viton-based oil seals derived from hot oil pump mechanical seal materials.

Results:

- No leaks after 8 months of daily riding

- Reduced engine temperature by 5°C

- Smoother idle and reduced oil consumption

Environmental Considerations

Motorcycle seals contribute to cleaner, safer transport:

- Prevent oil from leaking into the environment

- Extend the life of synthetic lubricants

- Improve fuel economy by reducing friction

When choosing seals, opt for REACH-compliant and RoHS-approved products. Many mechanical oil seal types now meet these standards due to their industrial use in environmentally sensitive areas.

Final Thoughts

Choosing the right oil seal for your motorcycle is about more than size—it’s about performance, longevity, and safety. Borrowing technologies from boiler feed water pump mechanical seal, hot oil pump mechanical seal, and advanced mechanical oil seal types ensures your ride stays smooth, efficient, and leak-free.

Don’t settle for stock replacements. Know your seal materials, geometry, and use-case. And remember—your bike deserves the same level of sealing technology that keeps power plants, ships, and industrial equipment running. Seal smart. Ride strong. Know more..