When comparing industrial vacuum sealer components, industrial seals, and automotive oil seals, it quickly becomes clear that not all sealing systems are built the same. While the fundamental purpose—keeping contaminants out and lubricants in—is consistent, the operational demands and design philosophies vary significantly between industrial and automotive environments. Understanding these differences is essential for engineers, procurement teams, and maintenance professionals who want performance without compromise. Know more..

Why the Right Seal Matters

Oil seals (also known as radial shaft seals) are critical to system efficiency and reliability. They prevent leakage of fluids (such as oil or grease) and keep out harmful elements like dust, water, or corrosive substances. In both industrial seals and automotive oil seals, even minor failure can lead to expensive repairs or system breakdown.

But the similarities end there. The working conditions of an industrial vacuum sealer and a high-revving car engine are entirely different. And so are the materials, tolerances, and lifespan expectations of the seals they rely on.

Industrial Oil Seals: Built for Endurance

1. Design Priorities

- Durability over speed: Most industrial seals operate under constant load but at moderate speeds.

- Larger dimensions: Often used in pumps, compressors, gearboxes, and rotating equipment with large shafts.

- High chemical resistance: They frequently encounter solvents, caustics, or extreme temperatures.

- Longer service life: Industrial machines can run continuously for months or years, so seal longevity is essential.

2. Application Examples

- Industrial vacuum sealers in food packaging or pharmaceuticals

- Pulp and paper processing machines

- Mining and quarrying equipment

- Energy production turbines

In an industrial vacuum sealer, for example, seals must withstand repetitive mechanical pressure, vacuum cycles, and exposure to food-grade oils or sterilizing agents. The challenge is not speed, but precision, chemical compatibility, and regulatory compliance.

3. Materials Used

- PTFE: Chemically inert and resistant to high temperatures

- Nitrile rubber (NBR): Cost-effective and fuel-resistant

- Fluoroelastomer (FKM): Excellent for harsh chemicals and heat

Automotive Oil Seals: Built for Performance

1. Design Priorities

- Speed and vibration resistance: Car engines and transmissions run at thousands of RPM.

- Compact design: Automotive oil seals must work within tight spatial constraints.

- Fuel compatibility: Must handle exposure to gasoline, diesel, and motor oil.

- Rapid thermal changes: Engines heat up and cool quickly, demanding seals with high thermal elasticity.

2. Application Examples

- Crankshaft and camshaft seals

- Transmission seals

- Axle and differential seals

- Power steering and air conditioning systems

In a racing engine, automotive oil seals must perform under extreme RPMs and vibration, often with minimal lubrication and frequent temperature spikes.

3. Materials Used

- ACM (Acrylic rubber): Good for oil resistance and heat aging

- Silicone rubber: Great for cold environments

- Fluoroelastomer (FKM): Also widely used in automotive for its resistance

Comparing Key Performance Factors

| Feature | Industrial Seals | Automotive Oil Seals |

| Operating Speed | Low to moderate | High RPM |

| Temperature Tolerance | -40°C to 200°C+ | -30°C to 150°C |

| Contaminant Exposure | Industrial solvents, abrasive dust | Engine fluids, road grime, fuel vapors |

| Load Variability | Typically constant | Varies with acceleration and RPM |

| Size Range | Often large (100mm+ shaft diameters) | Compact, designed for tight assemblies |

| Maintenance Intervals | Designed for longer durations | Regular service intervals (5,000–10,000 km) |

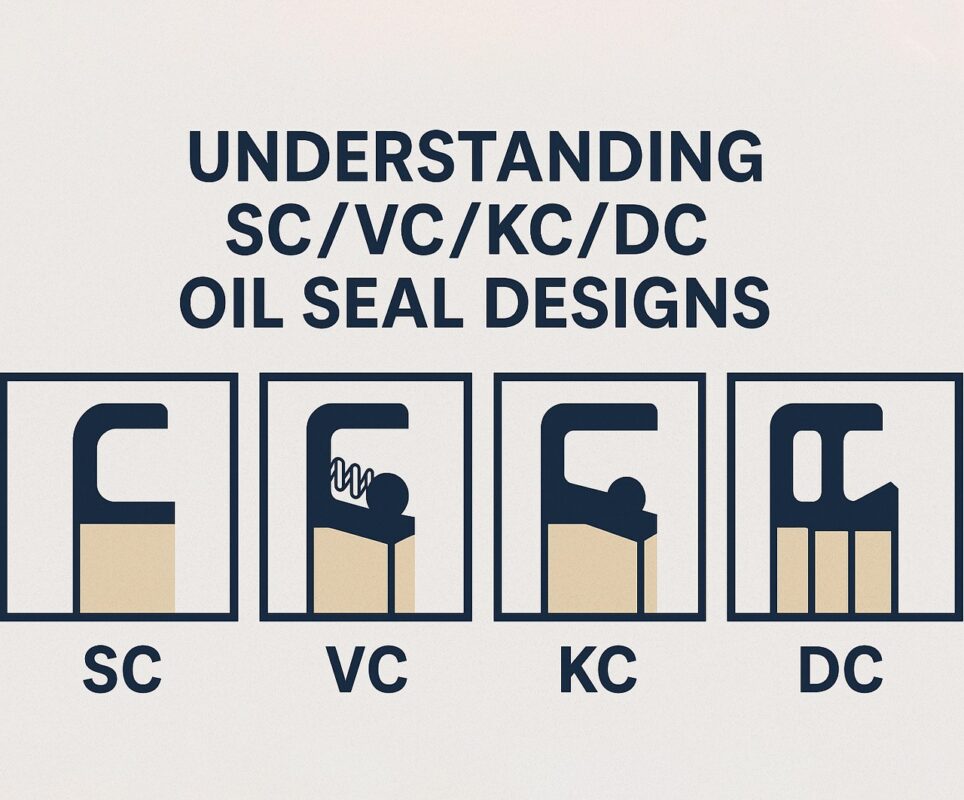

Customization and Precision

Industrial seals are often customized for specific machinery. Tolerances may be tighter, or materials adjusted to handle unique chemicals or pressures. Engineers may also include multiple sealing lips, integrated metal casings, or pressure-relief designs.

In contrast, automotive oil seals are typically mass-produced and highly standardized. Their design is fine-tuned for manufacturing efficiency and integration with high-speed production lines. However, performance isn’t sacrificed—in fact, some high-end auto seals feature multi-lip profiles and advanced materials normally reserved for aerospace or defense.

Unique Challenges of Industrial Vacuum Sealer Applications

Industrial vacuum sealer systems present their own complex sealing needs:

- Vacuum leakage: Any micro-leak can compromise product packaging or sterile environments.

- Regulatory standards: Seals often must meet FDA, USDA, or EU food-grade specifications.

- Cyclic loading: Repeated pressurization/depressurization can wear seals prematurely.

In these systems, seals must be:

- Non-toxic and chemically inert

- Resistant to mechanical fatigue

- Capable of handling both pressure and vacuum

This is a far cry from the high-speed, heat-intensive world of automotive oil seals, but no less demanding.

Real-World Examples

1. Industrial Food Packaging Line

A packaging company upgraded their industrial vacuum sealer seals to PTFE-coated fluoroelastomers. The result?

- 40% reduction in seal failures

- 20% faster vacuum cycle times

- 18 months between maintenance intervals

2. Performance Automotive Shop

A tuning garage replaced OEM automotive oil seals with FKM dual-lip alternatives. Benefits included:

- Zero oil leakage in high-RPM dyno testing

- Improved thermal performance

- Reduced blow-by and better crankcase pressure control

When to Choose Which Seal

Choose industrial seals when:

- Equipment operates continuously in a fixed location

- Systems involve vacuum, pressure, or chemical exposure

- Maintenance access is limited

- Sealing precision is tied to production quality

Choose automotive oil seals when:

- Sealing rotating shafts in mobile systems

- Speed, vibration, and fuel exposure are major concerns

- Space is limited and efficiency is paramount

Hybrid Systems: Where the Lines Blur

Some industries blur the line between automotive and industrial needs. Examples:

- Agricultural machinery: These use automotive oil seals for engines but industrial seals in hydraulics and PTO shafts.

- Electric vehicles (EVs): EV motors and battery cooling systems may use specially designed hybrid seals combining attributes from both categories.

- Autonomous delivery robots: Need compact, durable seals similar to automotive oil seals, but also operate in conditions resembling light-duty industrial seals.

Trends Shaping Seal Development

- Sustainability: Seals with longer life cycles and made from recyclable materials

- Smart Seals: Embedded sensors to monitor seal wear and predict failure

- Advanced Coatings: Friction-reducing or heat-resistant coatings for better performance

- Seamless Integration: Compact seals that integrate with electronics or sensors

Both industrial seals and automotive oil seals are evolving quickly, adapting to the increasingly digital and demanding nature of modern machines.

Final Thoughts: Know Your Application, Seal the Right Way

In the debate between industrial seals and automotive oil seals, there’s no one-size-fits-all answer. Each application has unique demands—whether it’s the constant vacuum cycles of an industrial vacuum sealer or the thermal spikes in a turbocharged engine.

Your best defense against failure is knowledge. Understand your system’s pressure, temperature, motion, and exposure conditions. Then match the seal material, profile, and design accordingly.

Whether you’re sealing a high-speed shaft or a vacuum chamber door, always remember: great performance starts with the right seal in the right place.