In a world where performance, safety, and longevity matter more than ever, contractors and OEM professionals are realizing that a single solution isn’t enough. For total system reliability—whether you’re maintaining a property or securing cargo—you need both surface repair and structural reinforcement. That’s why 2025 is all about combining the flexibility of driveway crack filler, the precision of loctite 542, and the high-level protection of a bolt seal. These three tools serve different purposes, but when integrated, they create a powerful, all-in-one sealing system for repair, bonding, and security. Know more..

Start at the Surface: The Role of Driveway Crack Filler

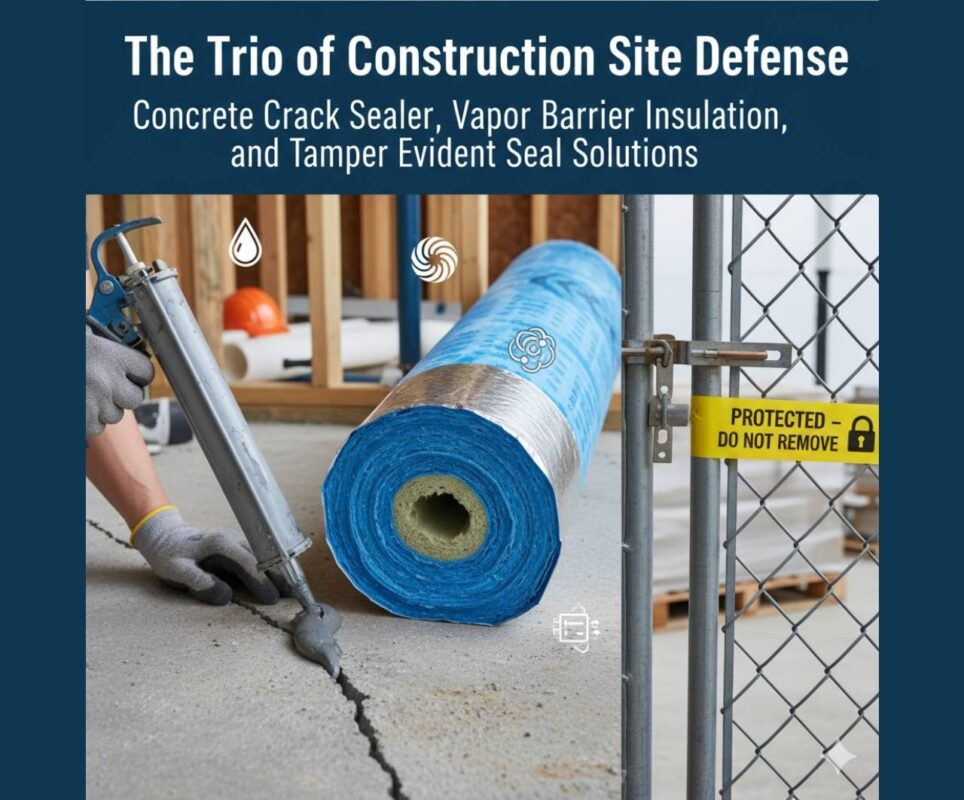

When it comes to exterior maintenance, the first visual sign of degradation is almost always cracking in asphalt or concrete. A top-tier driveway crack filler can make the difference between a quick fix and a lasting solution. Designed to expand and contract with temperature shifts, today’s best driveway crack filler options are flexible, weatherproof, and designed for industrial as well as residential use.

For contractors, using a high-performance driveway crack filler prevents water intrusion, freeze/thaw damage, and structural breakdown. In our OEM kits, we often pair driveway crack filler with other sealing components, allowing property managers or field crews to tackle multiple job types without swapping out tools or waiting for different materials.

Under the Surface: Why Loctite 542 Is a Game-Changer

Beyond surface repairs, many systems fail because of pressure loss or mechanical instability. That’s where loctite 542 steps in. This thread sealant is engineered for metal fittings and hydraulic systems that require fluid-tight seals—perfect for gas lines, valves, pipe systems, and compression fittings. While a driveway crack filler solves surface integrity, loctite 542 ensures that internal systems don’t leak, loosen, or corrode over time.

Here’s what makes loctite 542 essential in 2025:

- Seals instantly under low pressure

- Prevents vibration-induced loosening

- Resists most industrial fluids

- Withstands thermal cycling

We’ve integrated loctite 542 into repair kits for HVAC units, fuel delivery systems, and even fleet maintenance. It adds a layer of safety that goes far beyond the visible.

Lock It Down: The Strength of the Bolt Seal

Whether it’s securing cargo, locking up a container, or ensuring tamper-evidence on a high-value shipment, a bolt seal is your go-to for transport and logistics security. Unlike other seals, a bolt seal is uniquely tamper-resistant and ISO 17712-certified, making it the global standard for customs clearance and supply chain assurance.

When contractors combine bolt seal locking systems with internal thread sealing like loctite 542 and surface patching using driveway crack filler, they create layered protection. That’s total jobsite reliability—from the curb to the core and through to cargo departure.

Top bolt seal benefits:

- One-time use with irreversible break

- Laser-engraved tracking numbers

- Resistant to cutting and tampering

- Ideal for intermodal, trucking, and warehouse security

Unified Sealing: How These Products Work Together

While driveway crack filler, loctite 542, and the bolt seal serve different needs, they all center around sealing—just on different planes. Together, they give professionals an integrated toolkit for full-spectrum protection.

Here’s how it comes together:

- Use driveway crack filler to protect external surfaces—stopping moisture intrusion before it reaches critical structural layers.

- Apply loctite 542 inside junctions and metal fittings to ensure internal pressure retention and mechanical stability.

- Install a bolt seal on containers, toolboxes, or fuel supply lines to prevent theft or tampering.

It’s a layered approach to a single goal: total system reliability.

The 2025 Contractor’s Toolkit: Smart, Secure, and Sustainable

This year, we’ve seen a clear trend: professionals want fewer tools—but they want smarter, multi-functional ones. Our OEM partners and wholesale clients are asking for bundled solutions that combine surface repair, structural sealing, and shipment security all in one shipment. And that’s exactly what this trio—driveway crack filler, loctite 542, and bolt seal—delivers.

Bonus: These are all compact, shelf-stable, and easy to transport. So whether you’re on a road repair job or prepping materials in a facility, your sealing solutions stay protected and ready for action.

Industry Use Cases: Who Benefits Most?

- Road crews benefit from driveway crack filler that resists seasonal damage.

- Plumbers and HVAC techs rely on loctite 542 to stop microscopic leaks.

- Shipping and logistics operators trust the bolt seal to protect cargo in transit.

- Municipal contractors use all three when restoring sidewalks, sealing hydrants, and locking service boxes.

We’ve even seen bolt seal applications in disaster zones to lock up water supplies, while loctite 542 keeps critical plumbing from leaking and driveway crack filler prevents erosion in rescue paths.

Tips for Best Results on the Job

Driveway Crack Filler

- Clean the crack thoroughly before applying

- Use a flexible, rubberized compound

- Avoid overfilling—allow for expansion

Loctite 542

- Apply only to clean, dry threads

- Do not overtighten—let the chemical seal do the work

- Cures in 24 hours, but seals low-pressure lines immediately

Bolt Seal

- Always match the serial number on bolt and barrel

- Use bolt cutters to remove—never twist or pry

- Store in a cool, dry place to maintain barcode visibility

Saving Time and Money: ROI in Smart Sealing

Using the right combination of driveway crack filler, loctite 542, and bolt seal doesn’t just enhance performance—it saves money. When surface cracks go untreated, they lead to bigger structural issues. When fittings leak, systems fail. When containers are unsecured, cargo is at risk.

Here’s the ROI breakdown:

- Contractors save up to 30% in recurring surface repair costs by using commercial-grade driveway crack filler

- Industrial users reduce maintenance downtime with loctite 542 thread sealing

- Logistics companies avoid cargo loss or tampering fines by implementing bolt seal protocols

Why OEM Buyers Are Bundling These Tools

As a wholesale/OEM supplier, we’ve seen a spike in demand for “triple kits”—bundled systems including driveway crack filler, loctite 542, and bolt seal. Distributors love them for their versatility. Contractors appreciate the convenience. And everyone wins when jobs get done faster, safer, and with fewer product gaps.

We now offer custom-labeled kits for enterprise clients, giving them control over how the sealing systems are deployed—from warehouses to highway repair units.

Final Word: One Strategy, Three Solutions

When you think of sealing, don’t stop at the surface. The modern jobsite demands smarter integration—from ground-level maintenance to internal system reliability and secure closure. That’s where driveway crack filler, loctite 542, and bolt seal come together in perfect harmony.

And as we look toward a more sustainable, efficient, and security-conscious future, this trio sets the gold standard for how sealing products should work—together.

Looking for a bundled solution for your next project? Our team is ready to help you source the best driveway crack filler, high-performance loctite 542, and ISO-compliant bolt seal systems—delivered fast and OEM-ready. Know more..