For machinery operating in tough, dirty, and high-load conditions, durability is everything. Whether you’re servicing agricultural equipment, off-road vehicles, or industrial gearboxes, the right sealing technology can make the difference between consistent uptime and frequent failures. This is where the cassette oil seal, high-performance cassette seals, and the support of a trusted cassette seals manufacturer come into play. These seals are engineered to outlast traditional designs, protecting critical components from contamination and wear—even in the most brutal working environments.

In this article, we’ll explore how cassette oil seals function, what makes them different, and why engineers across industries rely on them for improved performance and reduced maintenance. Know more..

What is a Cassette Oil Seal?

A cassette oil seal is a fully integrated, multi-lip radial shaft seal system. Unlike standard oil seals, cassette seals come pre-assembled in a protective housing, often including an inner sleeve, outer shell, and a series of sealing lips. These components work together to form a layered barrier against contaminants like water, mud, dust, and grit.

Key Features of Cassette Oil Seals:

- Multi-lip sealing technology

- Integrated dust exclusion design

- Grease or oil lubrication compatibility

- Long-term sealing in high-wear environments

A reputable cassette seals manufacturer will often tailor seal construction to specific industry requirements, including materials, lip geometry, and lubricant retention properties.

How Cassette Seals Differ from Standard Seals

Traditional oil seals consist of a single elastomer lip that contacts the shaft. While effective in clean environments, they struggle in aggressive conditions where abrasive contaminants attack the sealing surface.

By contrast, cassette seals integrate multiple sealing lips and dirt-exclusion grooves within a rigid, unitized housing. This system:

- Keeps contaminants out with progressive sealing barriers

- Stabilizes the seal and shaft interface

- Reduces shaft grooving and wear

For anyone working in industries like mining, forestry, or agriculture, switching to a cassette oil seal is a long-term upgrade in durability and reliability.

Anatomy of a Cassette Oil Seal

Understanding the internal structure of a cassette oil seal highlights its strengths.

Components:

- Primary Seal Lip – Prevents lubricant from escaping.

- Dust and Dirt Exclusion Lips – Capture external contaminants.

- Wear Sleeve – Protects the shaft and acts as a sealing surface.

- Grease Packing – Optional for enhanced lubrication between lips.

- Outer Shell – Rigid frame ensures press-fit installation.

This advanced construction, available from leading cassette seals manufacturers, provides robust sealing even under heavy vibration, axial misalignment, and extreme temperatures.

Ideal Applications for Cassette Seals

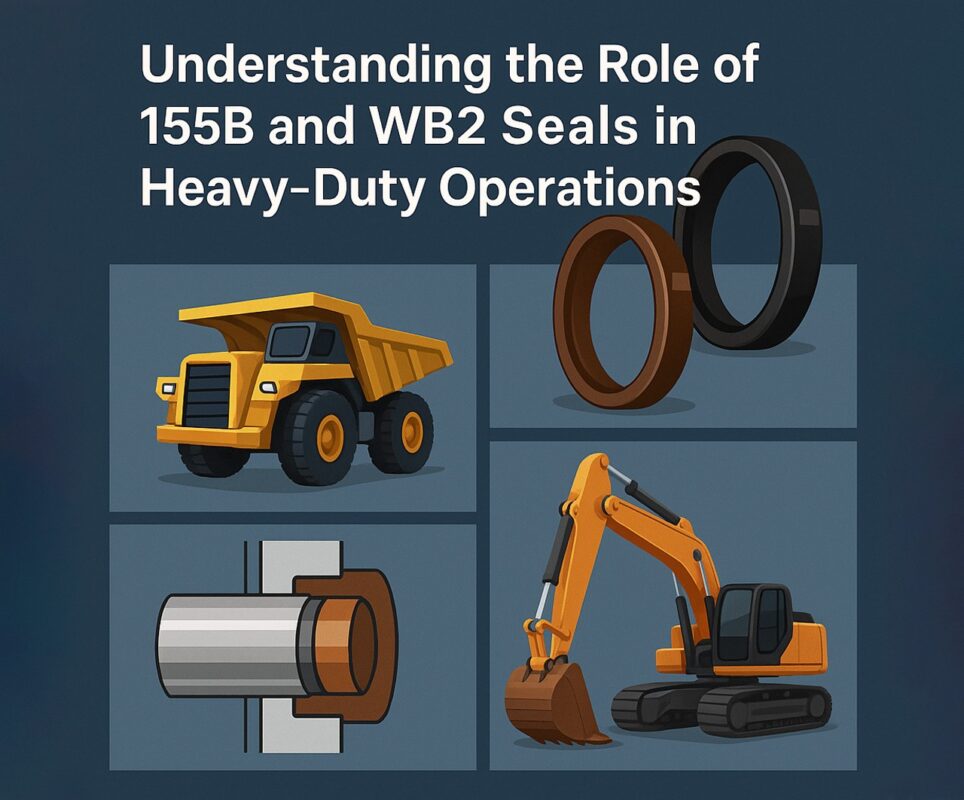

Because of their rugged design, cassette seals are ideal for equipment used in:

- Agriculture: Tractors, harvesters, balers

- Construction: Excavators, loaders, bulldozers

- Mining: Haul trucks, conveyor gearboxes

- Heavy Transport: Trailer axles, drive shafts

- Industrial Gearboxes: Oil-lubricated, high-speed rotating assemblies

In each of these applications, a cassette oil seal ensures uptime by protecting bearings and gearboxes from both lubricant loss and contamination ingress.

Benefits of Cassette Oil Seals in Harsh Environments

1. Superior Contaminant Resistance

Multi-lip designs and labyrinth-style grooves prevent mud, water, and dust from reaching internal components. This makes cassette seals the first choice for off-road and underground applications.

2. Extended Service Life

By shielding the shaft from wear and stabilizing the seal position, a cassette oil seal can outlast standard seals by 2–5x under the same conditions.

3. Reduced Maintenance

Less frequent seal replacements mean reduced labor and machine downtime. Many operators find that cassette seals reduce total cost of ownership over time.

4. Protection Against Shaft Damage

The integrated wear sleeve prevents shaft grooving—a common failure mode with standard seals.

5. Simplified Installation

With unitized construction, cassette seals are quicker and more foolproof to install, especially when provided by an experienced cassette seals manufacturer.

Material Options for Cassette Seals

Different environments demand different material combinations. A top cassette seals manufacturer will offer:

- Nitrile (NBR): Great for oil resistance and moderate temperatures.

- Fluoroelastomer (FKM): Excellent for chemical resistance and high temps.

- Polyacrylate (ACM): For high-speed, high-heat automotive uses.

- PTFE-coated lips: For extreme dry-running resistance and minimal friction.

These materials are typically molded into the seal lips or used for the wear sleeve, depending on the performance demands.

Partnering with the Right Cassette Seals Manufacturer

The performance of your cassette oil seal depends not only on the design but also on manufacturing quality. Here’s what to look for in a reliable cassette seals manufacturer:

1. Material Expertise

Look for a supplier that understands how elastomer properties interact with real-world operating conditions.

2. Custom Engineering

Sometimes off-the-shelf doesn’t cut it. Custom seal lip profiles, reinforcement materials, or dimensions might be needed for best fit and performance.

3. In-Stock Availability

Downtime is costly. A cassette seals manufacturer with quick turnaround and global shipping is a must.

4. Proven Track Record

Check industries served and customer success stories. Good manufacturers usually serve OEMs and major industrial operations.

How to Install a Cassette Oil Seal (the Right Way)

Even the best cassette oil seal won’t perform if it’s installed incorrectly.

Installation Tips:

- Clean the shaft thoroughly before mounting.

- Use a press-fit tool to seat the seal without distorting the lip geometry.

- Grease the lips lightly before installation to prevent dry start-up.

- Check alignment carefully. Misalignment accelerates wear and causes leaks.

A good cassette seals manufacturer will provide installation guides or training on best practices—especially for heavy equipment or complex systems.

Cassette Seals vs. Other Seal Technologies

| Feature | Cassette Oil Seal | Standard Oil Seal | Mechanical Seal |

| Contaminant Protection | Excellent | Poor to Moderate | High (but expensive) |

| Service Life | Long | Moderate | Very Long (if maintained) |

| Installation Ease | Easy | Easy | Complex |

| Cost | Moderate | Low | High |

| Shaft Protection | Excellent | Poor | Good |

While more expensive than a basic seal, cassette seals offer long-term savings and far greater reliability in tough environments.

Innovations in Cassette Seal Technology

Smart Monitoring Integration

Some modern cassette oil seals come with embedded sensors to monitor temperature, vibration, or wear—feeding data back into a predictive maintenance system.

Modular Designs

New cassette-style assemblies can be rebuilt or serviced without full disassembly, reducing long-term costs even further.

Eco-Friendly Materials

Leading cassette seals manufacturers are developing bio-based rubber blends and recyclable metal components to reduce environmental impact.

Final Thoughts

In any application where dust, moisture, or heavy load is a threat, the cassette oil seal proves its value. With superior multi-lip protection, long-lasting shaft preservation, and simplified installation, cassette seals outperform standard options across nearly every metric.

Choosing a high-quality cassette seals manufacturer ensures that you’re not just buying a product—you’re investing in reliability, uptime, and lower total cost of ownership. Whether it’s agriculture, construction, or industrial power transmission, cassette-style sealing is here to stay—and evolve.