Custom rubber seals are vital in keeping systems leak-proof, insulated, and functional across countless industries—from construction and automotive to medical equipment and consumer goods. But just like mass-produced components, custom seals can run into problems. Whether you’re managing components like a glass shower door rubber seal, industrial rubber sealing strips, or high-pressure gasket seal rubber, even minor performance issues can disrupt entire operations.

In this article, we’ll walk through the most common problems encountered with custom rubber seals and how to fix—or better yet, prevent—them. Know more..

1. Improper Fitment or Sizing

A surprisingly common issue with custom rubber seals is incorrect sizing. If a glass shower door rubber seal doesn’t form a perfect barrier, water escapes. If rubber sealing strips are too long or too tight, they buckle or split under pressure. And for gasket seal rubber, even a 1mm deviation in cross-section can compromise pressure sealing.

Causes:

- Inaccurate dimensions provided during ordering

- Miscommunication between design and manufacturing teams

- Thermal expansion/contraction not accounted for

Fixes:

- Always provide CAD files or 3D models for custom work

- Use digital calipers for precise measuring

- For dynamic environments, choose seals with expansion-tolerant materials

2. Material Incompatibility

Choosing the wrong elastomer for your application is a recipe for failure. Not every rubber works for every environment.

Symptoms:

- Swelling, cracking, or discoloration

- Seal becomes hard or brittle

- Poor adhesion to surfaces

Example:

A gasket seal rubber installed in a high-temperature pipe failed prematurely because it was made from standard NBR instead of a heat-resistant silicone blend.

Fixes:

- Match elastomer type to environmental demands (EPDM for water, Viton for oils, Silicone for heat)

- Request material test data from your supplier

- Perform accelerated aging tests on prototypes

3. Adhesion Failure

Whether it’s rubber sealing strips on automotive doors or glass shower door rubber seal components, seals must stay where they’re applied. Adhesion failure can cause movement, leaks, or detachment.

Causes:

- Poor surface prep (dust, grease, rust)

- Incompatible adhesive type

- Incorrect pressure applied during installation

Fixes:

- Clean surfaces with isopropyl alcohol before application

- Use pressure-sensitive adhesive (PSA) matched to substrate

- Apply even pressure for 30+ seconds during install

- Consider mechanical retention (clips, screws) for high-stress applications

4. Compression Set

This refers to the permanent deformation of a seal after long-term compression. In gasket seal rubber, this can cause leaks. On glass shower door rubber seal setups, this allows water to bypass the seal path.

Causes:

- Low-quality rubber materials

- Improper durometer (hardness)

- Over-compression during installation

Fixes:

- Use high-performance materials like silicone or polyurethane

- Choose appropriate durometer ratings (typically 60–70 Shore A for most static seals)

- Allow for compression recovery in seal design

5. UV and Ozone Degradation

For seals exposed to outdoor environments, UV light and ozone can degrade materials over time—especially in rubber sealing strips around windows and doors.

Signs of Degradation:

- Surface cracking

- Fading or chalky appearance

- Loss of elasticity

Fixes:

- Use UV-resistant materials like EPDM or silicone

- Avoid materials like natural rubber for exterior use

- Store unused seals in cool, shaded, and dry environments

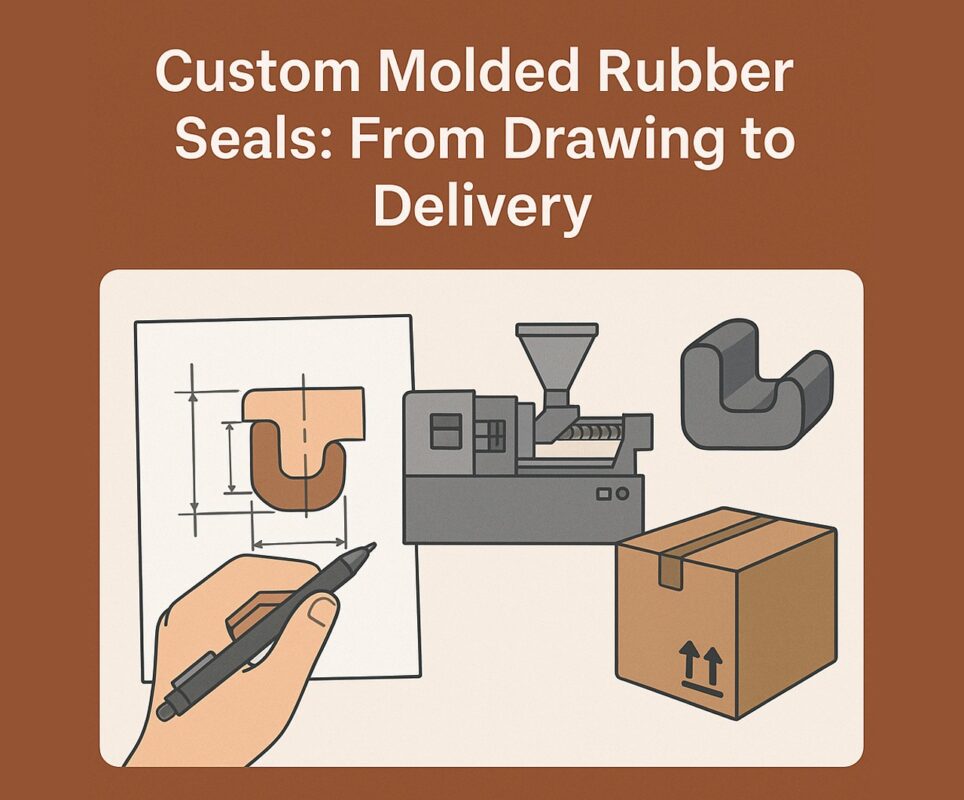

6. Poor Surface Finish or Flashing

Sometimes, custom rubber seals arrive with a rough surface, burrs, or excess material (called flashing). This can interfere with sealing, especially for gasket seal rubber in high-pressure systems.

Causes:

- Incomplete mold cleaning

- Mold wear and tear

- Poor quality control during de-flashing process

Fixes:

- Request visual inspection reports from your manufacturer

- Choose molded rather than extruded seals for complex geometries

- Specify critical surface finish parameters in your drawings

7. Tearing During Installation

Especially in tight fits or sharp-edged environments, seals like glass shower door rubber seal components or long rubber sealing strips can tear during install.

Contributing Factors:

- Excessive stretching

- Sharp housing edges

- Low tensile strength material

Fixes:

- Use install tools like seal pushers or guides

- Lubricate seals with silicone grease

- Round off sharp metal or plastic edges before installation

- Select a higher tensile strength rubber (e.g., neoprene or polyurethane)

8. Inconsistent Durometer (Hardness)

In custom manufacturing runs, inconsistent rubber hardness can lead to unreliable performance. A gasket seal rubber rated at 70 Shore A that arrives at 60 or 80 won’t perform the same under pressure.

How to Identify:

- Use a Shore durometer to measure different areas of the batch

- Check with supplier for batch testing certification

Fixes:

- Request durometer range tolerances in your PO (e.g., 70 ±5 Shore A)

- Choose manufacturers with ISO 9001 or comparable QC systems

- Spot-test each delivery upon receipt

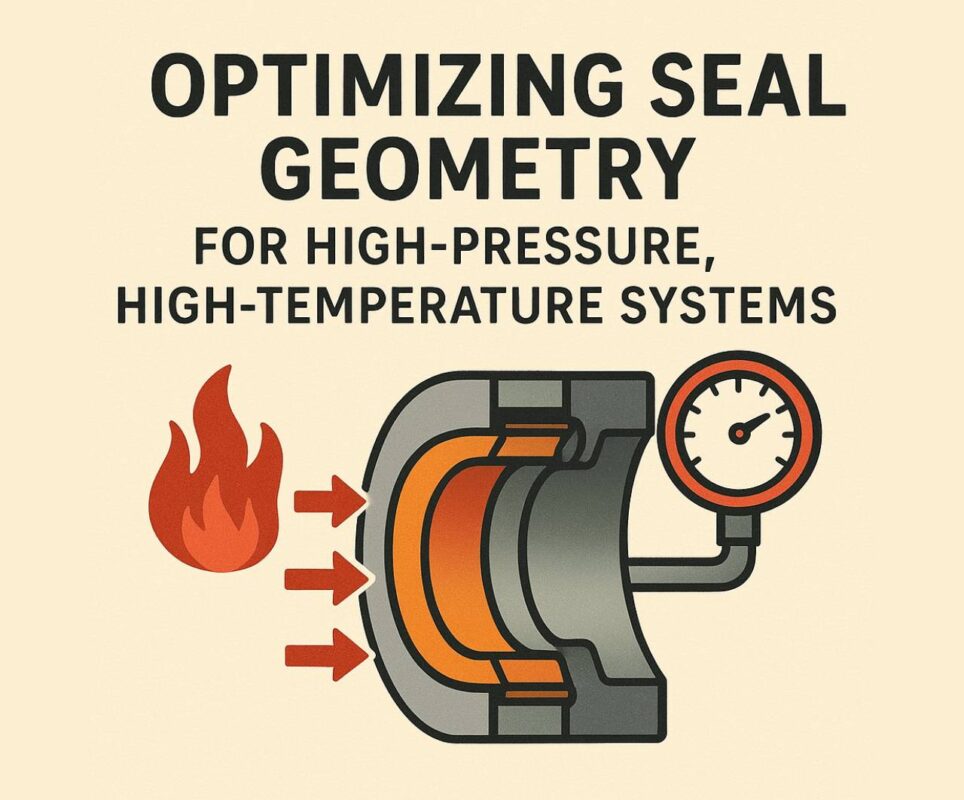

9. Thermal Expansion and Contraction

Seals that experience temperature swings—like glass shower door rubber seal components near steam, or gasket seal rubber in engine compartments—can shrink or expand excessively.

Fixes:

- Use thermally stable materials like silicone or fluorosilicone

- Incorporate expansion gaps in housing design

- Add reinforcement ribs for dimensional integrity

10. Visual Mismatch or Color Variance

In consumer applications (e.g., rubber sealing strips for home goods or appliances), inconsistent color can affect perceived quality.

Fixes:

- Use pigment-stable rubber compounds

- Specify Pantone color codes

- Request a color-matched prototype before full production

Working with the Right Manufacturer

A lot of these problems can be prevented by working with experienced suppliers who specialize in your type of rubber application. Ask questions like:

- What’s your experience with gasket seal rubber systems?

- Do you manufacture glass shower door rubber seal components?

- How do you ensure consistency in rubber sealing strips production?

A reputable manufacturer will be transparent about materials, tolerances, and testing.

Case Study: Shower Door Seal Rework

A bathroom fixture brand experienced multiple warranty claims due to glass shower door rubber seal leaks. Investigation revealed the seals were made of non-UV-resistant PVC instead of EPDM.

Solution:

- Switched to black EPDM with built-in anti-fungal agents

- Tightened durometer specs to ±3 Shore A

- Added adhesion ribs for better retention in the glass channel

Result:

- Leak complaints dropped 85%

- Return rates reduced

- Customer satisfaction scores improved

Final Thoughts

Custom rubber seals offer tailored performance—but they also bring unique challenges. Whether you’re designing rubber sealing strips, selecting a glass shower door rubber seal, or replacing a worn gasket seal rubber, understanding potential failure points helps you choose better materials, designs, and manufacturers.

By addressing these common problems proactively, your seals will not only perform better but also last longer—ensuring safety, efficiency, and user satisfaction in every application.

Choose smarter. Specify clearly. Seal confidently.