When working with rotating shafts and mechanical systems, selecting the right type of oil seal can mean the difference between flawless operation and costly breakdowns. With so many options available from top oil seal manufacturers, including a wide range of metric oil seals and specialty solutions like the SKF oil seal, understanding the distinctions between SB, VB, KB, and DB oil seals is essential. Each has unique design features, materials, and application profiles tailored for different industrial needs. Know more..

Why Oil Seal Selection Matters

Oil seals (also called shaft seals, rotary shaft seals, or radial lip seals) serve one main purpose: to prevent the leakage of lubricants and the ingress of contaminants. But not all oil seals are created equal. Depending on shaft speed, pressure, chemical exposure, and mechanical tolerances, the wrong seal can cause premature failure, shaft wear, and production downtime. That’s why oil seal manufacturers offer various profiles—like SB, VB, KB, and DB—each engineered for specific conditions and performance requirements.

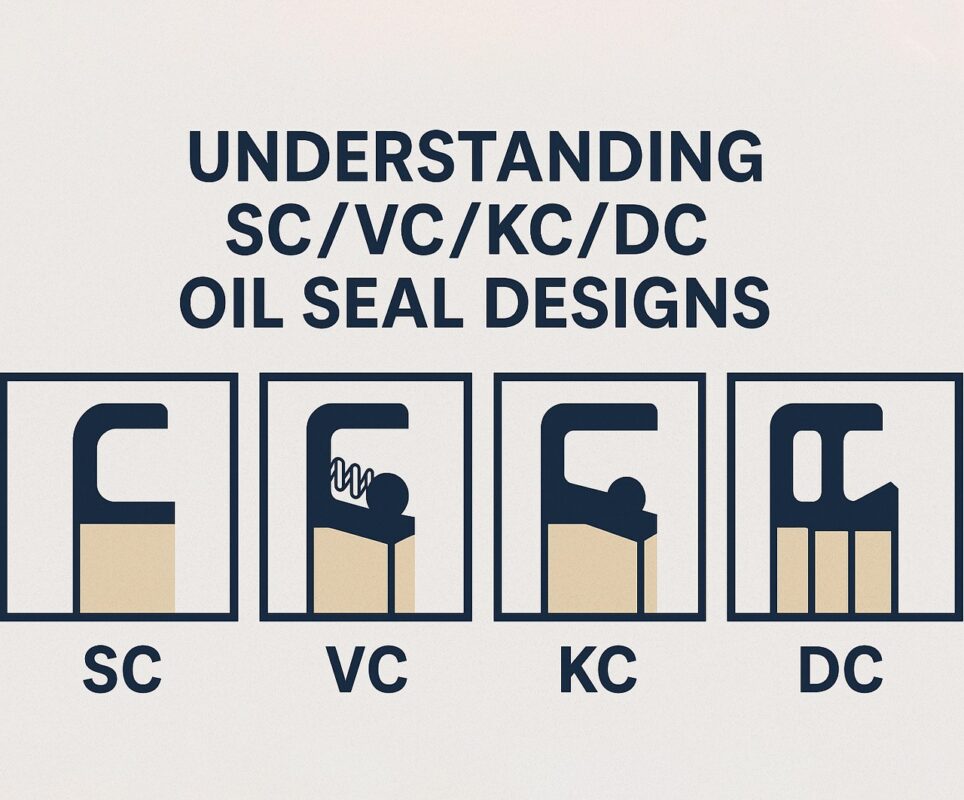

Understanding the Oil Seal Codes: SB, VB, KB, and DB

These letter codes refer to different design types of oil seals, commonly used across industries like automotive, heavy machinery, food processing, and marine applications.

1. SB Oil Seal

SB refers to a single-lip oil seal with no auxiliary dust lip and typically with a metal case. It is used in low to moderate speed environments where contamination from the outside is minimal.

Applications:

- Light-duty gearboxes

- Electric motors

- Pumps in clean environments

Advantages:

- Cost-effective

- Easy to install

- ow friction

2. VB Oil Seal

VB is a single-lip seal with a rubber (fully covered) casing. It is typically used in metric applications and offers better corrosion resistance.

Applications:

- Automotive wheel hubs

- Marine equipment

- Agriculture machinery

Advantages:

- Corrosion resistant

- Ideal for metric oil seals setups

- Better grip in split housing applications

3. KB Oil Seal

KB is similar to VB but includes a dust lip (secondary lip), providing added protection against contamination. This design is ideal for harsh environments with dirt, water, or chemicals.

Applications:

- Construction machinery

- Agricultural equipment

- Mining gearboxes

Advantages:

- Dual sealing (oil retention + dust exclusion)

- Longer lifespan in dirty conditions

4. DB Oil Seal

DB stands for a double-lip oil seal with metal casing and both sealing and dust lips. It’s one of the most robust designs, suitable for challenging operating environments.

Applications:

- Heavy-duty gearboxes

- Industrial mixers

- Cranes and lifting equipment

Advantages:

- Maximum sealing protection

- Resistant to high-speed and high-pressure conditions

- Preferred by SKF oil seal experts for critical systems

Comparing Seal Designs at a Glance

| Feature | SB | VB | KB | DB |

| Lip Configuration | Single | Single | Dual | Dual |

| Dust Lip | No | No | Yes | Yes |

| Casing Material | Metal | Rubber | Rubber | Metal |

| Corrosion Resistance | Low | High | High | Moderate |

| Application Cleanliness | Clean | Moderate | Harsh | Severe |

How to Match Oil Seal Type to Your Application

Choosing between SB, VB, KB, and DB seals depends on several criteria:

1. Operating Environment

- Clean and dry? SB or VB will likely suffice.

- Dusty or wet? KB or DB with a dust lip is better.

2. Casing Fitment

- For split or imperfect housings, a rubber-cased VB oil seal conforms better.

3. Pressure and Speed

- High-speed shafts benefit from DB seals with metal rigidity and dual lips.

- Low-speed, low-pressure equipment can use SB or VB options.

4. Shaft Size and Tolerance

- Metric oil seals (like VB, KB) are ideal for European-standard shaft diameters.

- Always check compatibility with OEM shaft finish and hardness.

5. Contamination Risk

- If the seal faces direct exposure to mud, water, or abrasive dust, go for KB or DB seals.

Creative Industry Applications

Here are real-world examples that show how to optimize oil seal selection:

1. SKF Oil Seal in Wind Turbines

DB oil seals are used in the nacelle gearbox of wind turbines. The dual-lip configuration protects against rain, dust, and high rotational speeds while ensuring lubricant retention for long service intervals.

2. Metric Oil Seals in Electric Scooters

VB oil seals provide a cost-effective and corrosion-resistant solution for compact hubs in electric scooters and light EVs.

3. Oil Seal Manufacturers in Food Processing

KB oil seals with FDA-approved rubber compounds ensure clean operation in food mixers while blocking flour dust and moisture ingress.

4. Construction Equipment

Heavy-duty cranes and excavators rely on DB seals for rugged hydraulic systems. High-pressure cycles and dirt exposure make single-lip seals unreliable here.

Material Choices from Leading Oil Seal Manufacturers

Different applications demand different materials. Top oil seal manufacturers like SKF, NOK, and Trelleborg provide a variety of options:

- NBR (Nitrile Rubber): Good for oil resistance and affordability

- FKM (Viton): Heat and chemical resistance for high-performance setups

- Silicone: Great for low-temperature flexibility

- PTFE-lipped seals: Ideal for dry-running or chemically aggressive systems

Pairing the right design (SB, VB, KB, DB) with the right material maximizes performance.

Tips for Installation and Maintenance

- Cleanliness is critical: Ensure the shaft and housing are free of dirt and burrs.

- Lubricate during install: Prevents lip scoring and dry start-up.

- Use correct tools: Avoid damaging the seal lip during fitting.

- Check orientation: Dust lip should face outward, sealing lip inward.

- Inspect regularly: Look for signs of wear, leakage, or hardening.

Even the best SKF oil seal will fail if installed incorrectly.

Future Trends in Oil Seal Design

As systems become faster, smaller, and more efficient, oil seal manufacturers are pushing innovation:

- Smart Seals: Embedded sensors to detect wear, heat, and vibration.

- Recyclable Materials: More eco-friendly elastomers are emerging.

- Self-lubricating Lips: Reduce maintenance in inaccessible locations.

- Custom Metric Oil Seals: 3D printing is enabling one-off designs for prototyping.

These trends are making SB, VB, KB, and DB oil seals smarter and more application-specific.

Final Thoughts: Choosing with Confidence

Whether you’re working with industrial gearboxes, compact e-mobility devices, or heavy construction machinery, selecting between SB, VB, KB, and DB oil seals is more than just a technical decision—it’s a performance investment. By aligning your needs with the right seal design, material, and casing, you reduce risk, boost efficiency, and extend equipment lifespan.

Oil seal manufacturers provide vast catalogs, and the right choice often comes down to understanding subtle differences. Metric oil seals like VB and KB are best when space, corrosion resistance, and regional standards are in play. For extreme conditions or high-performance needs, nothing beats a SKF oil seal in DB configuration.

So, before your next equipment build or seal replacement, take a close look at your application—and make sure your choice between SB, VB, KB, and DB oil seals is sealing the deal for long-term success.