Sealing technology plays a vital role in modern industrial and mechanical systems, and when it comes to precision and reliability, DIN 3869 ED rings stand out. Whether you’re sourcing a resilient oring in silicone, high-performance Kalrez o rings, or developing custom o rings for unique environments, understanding ED rings—especially in accordance with DIN 3869 standards—can give your sealing systems a significant edge.

DIN 3869 ED rings are more than just another sealing element. Designed for static applications, particularly in hydraulic and pneumatic systems, these rings provide a precise fit and superior resistance against extrusion. With the rise of bespoke engineering needs and aggressive chemical environments, integrating ED rings alongside custom o rings, Kalrez o rings, or even a well-formulated oring in silicone provides multi-layered security. Know more..

What Are DIN 3869 ED Rings?

DIN 3869 ED rings are precision-molded sealing elements used primarily in threaded hydraulic fittings. They are defined by a German industrial standard (DIN) and offer consistent performance under high pressure. The “ED” in their name stands for “Elastomeric Seal,” and these rings are designed to be installed in grooves to seal off against cylindrical surfaces, like male-threaded pipe fittings.

Unlike traditional O-rings, DIN 3869 ED rings have a rectangular cross-section. This provides enhanced resistance to extrusion and better stability under pressure.

Key Characteristics:

- Rectangular cross-section

- Designed for static applications

- Prevent twisting or rolling under load

- Compatible with high-pressure hydraulic fittings

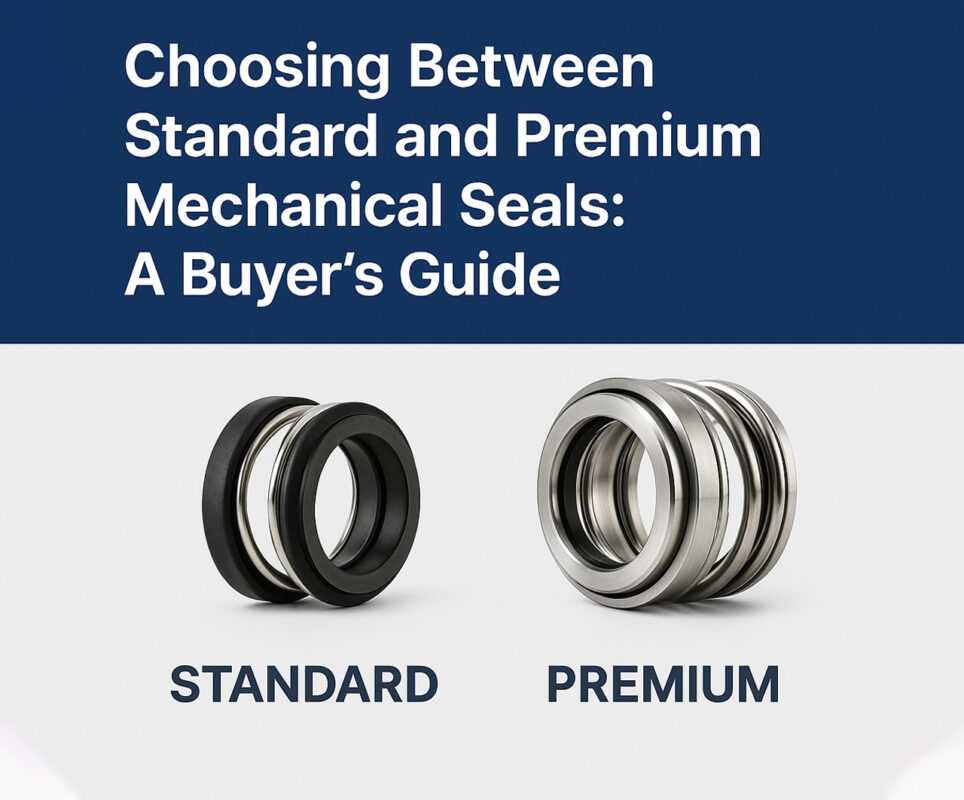

Comparing ED Rings and Traditional O-Rings

When comparing a DIN 3869 ED ring to a standard oring in silicone, several differences emerge:

- Stability: ED rings maintain shape under axial compression better than round O-rings

- Extrusion resistance: The square cross-section handles high-pressure environments more effectively

- Design specificity: ED rings are tailored to groove dimensions in DIN hydraulic fittings

However, for dynamic or general sealing needs, traditional round O-rings—including Kalrez o rings for chemical resistance or custom o rings for tailored specs—may be more suitable.

Material Options for ED Rings

Material selection is crucial to performance and longevity. While you may be using a oring in silicone for temperature resistance or Kalrez o rings for chemical compatibility, ED rings are typically made from:

- NBR (Nitrile Rubber): Good general-purpose choice, resistant to oils and greases

- FKM (Fluorocarbon/Viton®): Superior heat and chemical resistance

- EPDM: Best for water and steam but not for oil

- Kalrez® (FFKM): Top-tier option when combined chemical and thermal resistance is required

Kalrez o rings are often used in applications with DIN 3869 ED rings for their unparalleled chemical resilience.

Common Applications of DIN 3869 ED Rings

These rings are especially effective in:

- Hydraulic systems

- Pneumatic fittings

- Industrial pipe connections

- Automotive fuel injection systems

- Aerospace hydraulics

By using ED rings in conjunction with custom o rings, engineers can tailor systems for dual performance—static sealing from the ED ring, and dynamic resilience from the O-ring.

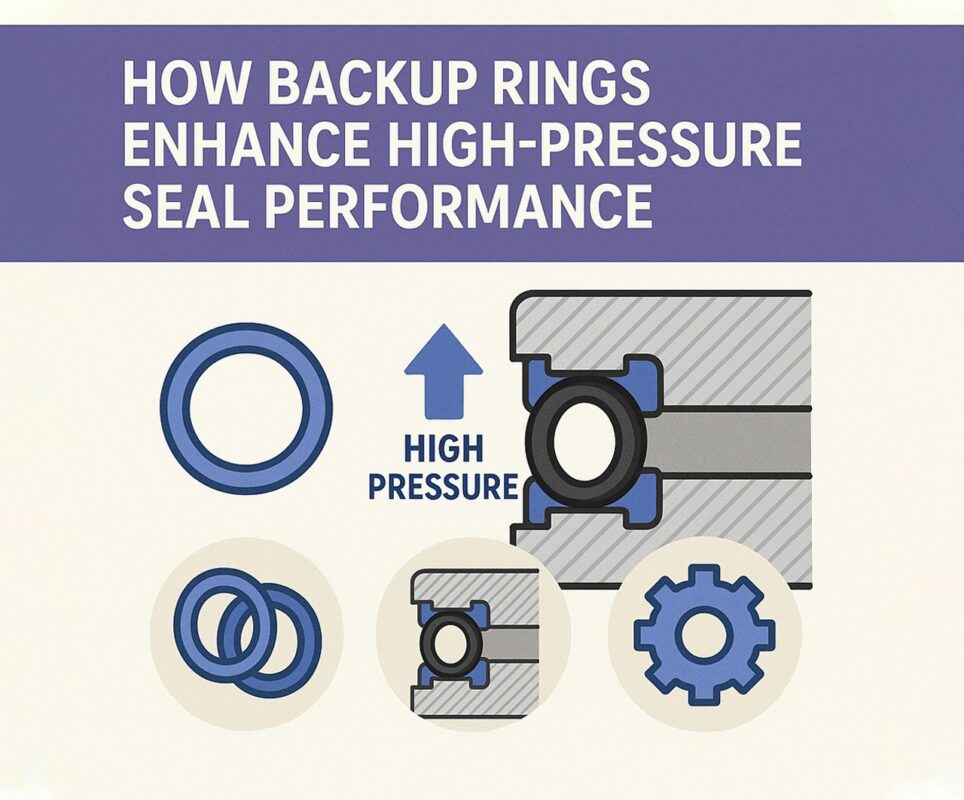

Why ED Rings Are Critical in Hydraulic Fittings

In DIN-compliant threaded fittings, traditional sealing methods like thread tape or basic oring in silicone are not enough. DIN 3869 ED rings offer:

- Leak-Free Threaded Connections: Designed to fit into machined grooves in fittings

- Resistance to High Pressure: Up to 400 bar in static systems

- Improved Torque Consistency: Sealing does not depend on overtightening

These benefits significantly reduce wear and risk of seal displacement, unlike improperly seated custom o rings or low-grade round seals.

ED Rings vs. Bonded Seals

Bonded seals, or Dowty washers, also provide threaded joint sealing, but they differ from ED rings in that they incorporate a metal washer bonded to a rubber sealing element. Here’s how they compare:

- ED Rings: More suitable for hydraulic systems with DIN port configurations

- Bonded Seals: Better for flat-face flange connections

In high-vibration settings, combining ED rings with Kalrez o rings or enhanced custom o rings provides an ideal sealing ecosystem.

Installation Tips for DIN 3869 ED Rings

Correct installation ensures optimal performance. Follow these steps:

- Clean the groove and threads thoroughly

- Inspect for burrs or sharp edges

- Use a lubricant compatible with the elastomer material

- Seat the ED ring in the groove without stretching

- Torque the fitting to specification

Avoid over-compression, which can happen when mixing ED rings with generic oring in silicone options that aren’t designed for the groove.

Combining ED Rings with Kalrez and Silicone O-Rings

In specialized applications, hybrid sealing solutions are becoming more common:

- Kalrez o rings: Used alongside ED rings in chemical plants and laboratories where aggressive acids and bases are present

- Oring in silicone: Applied where thermal extremes exist, such as ovens, autoclaves, or cryogenics

- Custom o rings: Tailored to match unique pressure, material, or dimensional constraints, and often paired with ED rings in aerospace or defense systems

Each material brings a unique strength, and using them strategically enhances reliability.

Customization Possibilities

Manufacturers can now offer:

- ED rings in non-standard dimensions

- Dual-hardness profiles

- Custom cross-sections for complex groove shapes

- FDA-grade elastomers

If you’re already specifying custom o rings, it makes sense to explore similar tailoring for your ED ring needs. The combined system can then match pressure, chemical, and regulatory requirements perfectly.

Environmental and Regulatory Considerations

Depending on the application, your seals—including Kalrez o rings, oring in silicone, and ED rings—may need to comply with:

- FDA and USP Class VI: For food and pharmaceutical use

- REACH/RoHS: For environmental compliance

- ASTM and ISO standards: For performance verification

Top-tier seal providers offer traceable batch records and certifications to ensure your systems are compliant.

When to Replace an ED Ring

While durable, ED rings aren’t permanent. Replace when:

- Signs of wear or flattening are visible

- Frequent pressure cycling causes deformation

- Fluid leakage is observed

- Maintenance intervals dictate proactive replacement

Always source replacements from a reliable supplier that also offers Kalrez o rings, oring in silicone, and custom o rings—consistency across your seal inventory reduces downtime.

Choosing the Right Supplier

Look for:

- Access to a range of elastomers

- Capability for custom mold design

- Fast lead times for prototype or small-batch custom o rings

- Technical support for groove and torque recommendations

Premium sealing companies help optimize both performance and regulatory compliance.

Final Thoughts

DIN 3869 ED rings may not be flashy, but in the world of fluid sealing, they’re indispensable. From improving hydraulic fitting performance to complementing systems that rely on oring in silicone, Kalrez o rings, or custom o rings, ED rings are the quiet achievers in your sealing lineup.

By understanding their advantages, materials, and installation strategies, you can build longer-lasting, safer, and more efficient mechanical systems. Whether you’re spec’ing out a new design or upgrading a legacy system, don’t underestimate the power of a well-chosen ED ring.