When it comes to dynamic sealing in high-performance systems, engineers are often faced with a critical choice: PTFE seal ring, Flex Seal liquid rubber, or a traditional rubber window seal? These materials may appear similar in sealing function, but their chemical composition, mechanical behavior, and durability differ significantly—especially in systems where parts are moving, vibrating, or enduring fluctuating pressure. In dynamic applications where sealing failure isn’t an option, the right choice of material can enhance performance, reduce maintenance, and extend equipment life. Know more..

Understanding the Basics: PTFE and Rubber in Sealing Systems

Sealing in dynamic environments refers to managing leakage in applications with motion—rotary, reciprocating, or oscillating. These motions introduce friction, heat, and wear challenges that demand a robust, adaptable sealing material.

- PTFE (Polytetrafluoroethylene): Known for its low friction and excellent chemical resistance, PTFE is a synthetic fluoropolymer used in high-performance applications. A PTFE seal ring offers stability under pressure, extreme temperatures, and aggressive chemicals.

- Rubber: Natural or synthetic elastomers like Nitrile, EPDM, or Silicone provide flexibility and elastic recovery. Flex Seal liquid rubber is a modern adaptation of rubber used to coat, protect, and seal uneven surfaces. The rubber window seal, a common form of elastomeric sealing, ensures airtight sealing in automotive and architectural settings.

Key Differences Between PTFE and Rubber

| Property | PTFE Seal Ring | Flex Seal Liquid Rubber / Rubber Window Seal |

| Temperature Resistance | -200°C to +260°C | -40°C to +120°C |

| Chemical Resistance | Excellent | Moderate to Good (depends on compound) |

| Friction Coefficient | Very Low | Moderate to High |

| Elasticity | Low (rigid) | High (flexible, elastic recovery) |

| Wear Resistance | High (in dynamic contact) | Moderate |

| Installation Ease | Requires machining/fitment | Easily applied or installed |

Dynamic Sealing Requirements: What Matters Most

In dynamic environments, the following criteria determine the best sealing material:

- Wear Resistance

- Friction Management

- Temperature Fluctuation Tolerance

- Chemical Compatibility

- Pressure Withstanding Capability

- Flexibility and Compression Recovery

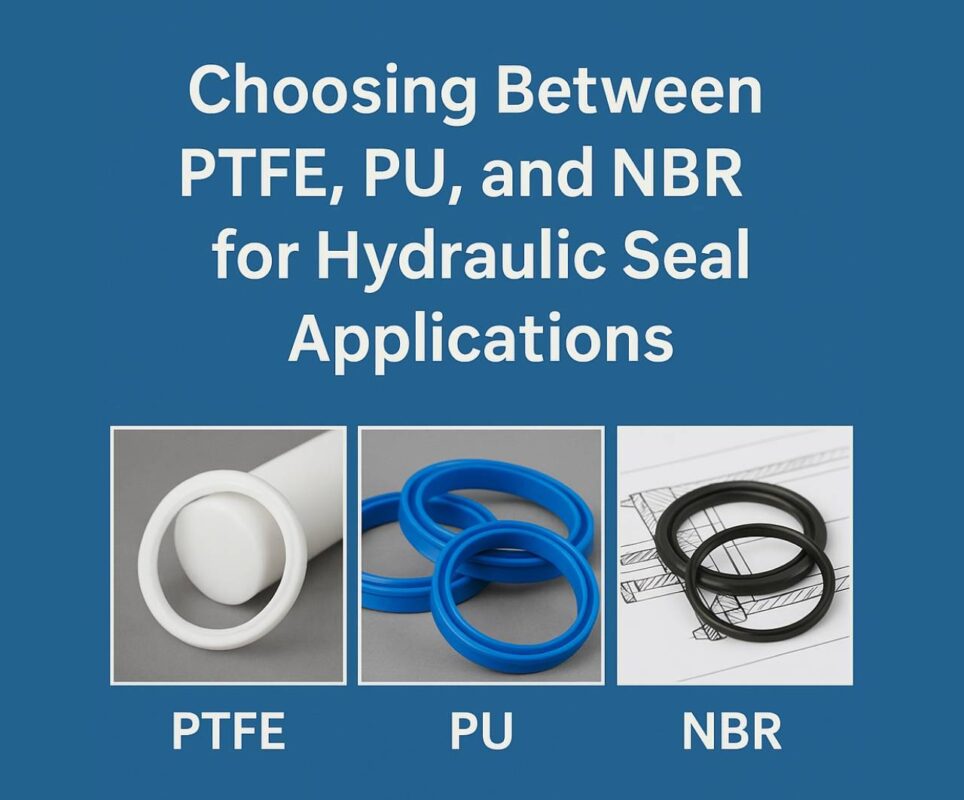

When to Use a PTFE Seal Ring

The PTFE seal ring shines in precision, high-load applications. It is best for:

- Hydraulic actuators

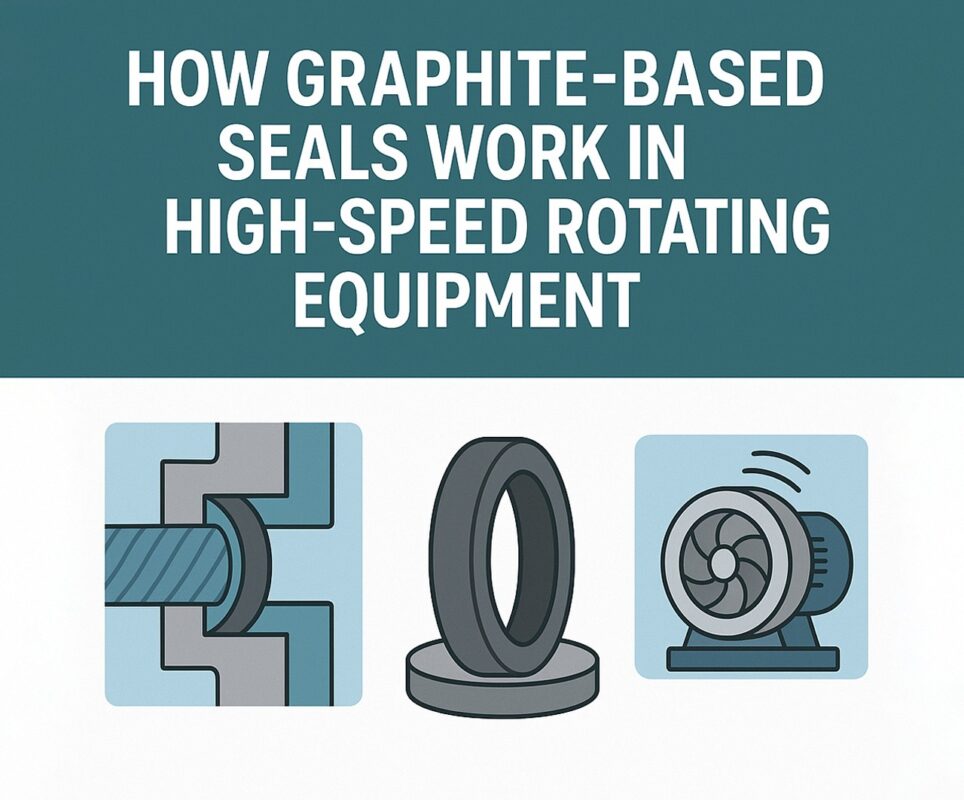

- Rotary shaft seals in motors and gearboxes

- Aerospace valve systems

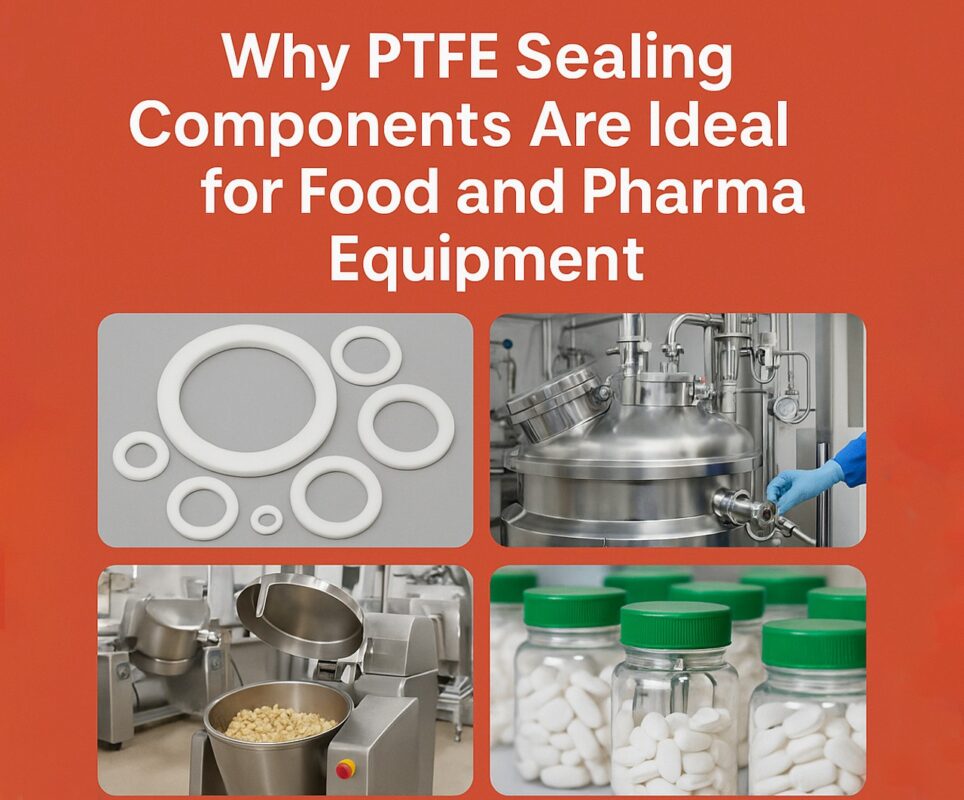

- Food-grade sealing with aggressive cleaners

- Pharmaceutical pumps and mixers

Advantages:

- No swelling or degradation in chemical exposure

- Stable at both cryogenic and extreme heat

- Minimal friction reduces energy loss and wear

- Long service intervals in rotating equipment

Limitations:

- Cannot compress like rubber

- Must be machined or designed into specific housing grooves

When to Use Flex Seal Liquid Rubber or Rubber Window Seal

Flex Seal liquid rubber offers sealing versatility on irregular or non-machined surfaces. It’s ideal for:

- Emergency repairs

- Gaps, leaks, or cracks in roofing and plumbing

- Protective coatings on electrical boxes or vents

Meanwhile, rubber window seals excel in:

- Automotive windshields and door seals

- HVAC systems

- Marine hatches and enclosures

Advantages:

- Flexible and easy to apply or mold

- Good shock absorption and vibration damping

- Readily available and cost-effective

Limitations:

- Degrades under UV or chemical exposure

- Can wear quickly in rotary applications

Real-World Comparisons: PTFE vs. Rubber in Action

1. Automotive Door Systems

A rubber window seal keeps air and water out while allowing the window to move. However, in the engine’s dynamic components like turbo seals or shaft bearings, PTFE seal rings are preferred due to their resistance to heat and oil.

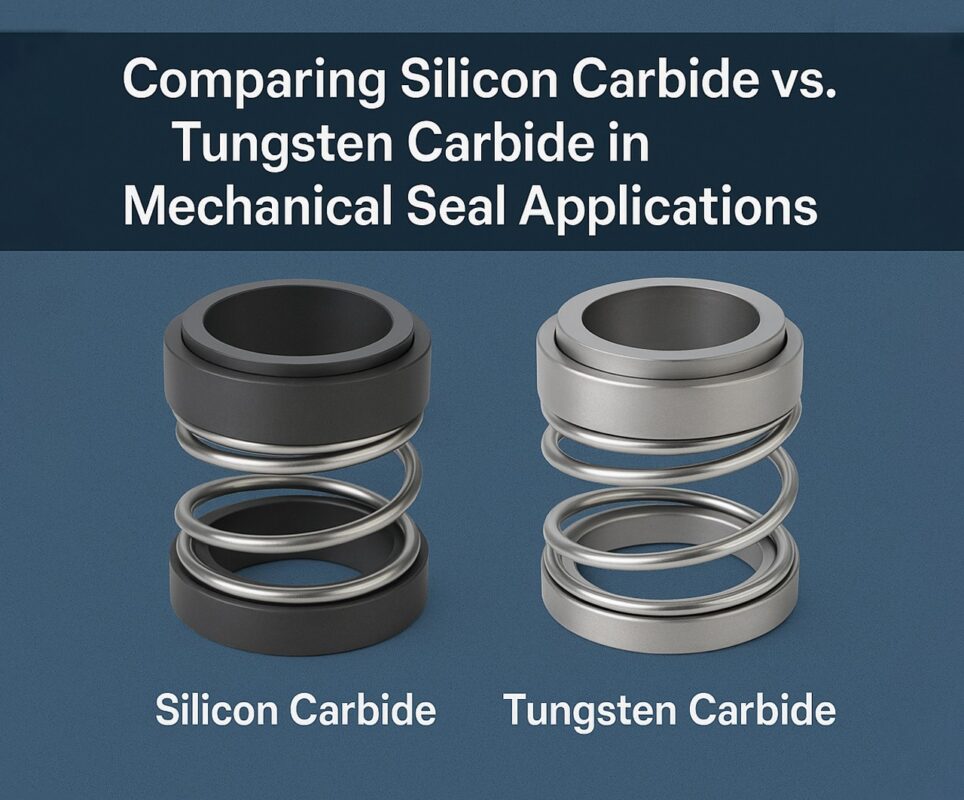

2. Rotary Pumps in Chemical Plants

PTFE rings survive where rubber fails—handling acids, alkalis, and solvents over long periods without swelling or cracking. A rubber seal would break down within weeks.

3. Construction and Home Repairs

Flex Seal liquid rubber is the go-to solution when sealing around ducts, roofing seams, or water tanks. PTFE cannot conform to these irregular surfaces.

Creative Applications of PTFE and Rubber

- PTFE Seal Ring Innovations:

- Spring-energized PTFE lip seals in spacecraft

- Multi-laminate PTFE composite seals in cryogenic tanks

- Flex Seal Liquid Rubber Use Cases:

- Waterproofing outdoor electronics

- Temporary tire patching

- Garden irrigation system repairs

- Rubber Window Seal Evolution:

- Weatherproofing for tiny homes and vans

- High-clarity marine-grade rubber with UV inhibitors

Hybrid Sealing Systems: Best of Both Worlds

Some engineers combine both materials:

- Rubber for outer flexibility, PTFE for inner contact with high-pressure fluid

- Liquid rubber coating over PTFE seals for extra impact resistance

This hybrid approach is especially useful in marine, aerospace, and high-vibration industrial systems.

Maintenance and Replacement Considerations

PTFE Seal Rings:

- Inspect for lip wear or cracking

- Replace during scheduled overhauls

- May require precise alignment during installation

Flex Seal Liquid Rubber & Rubber Window Seals:

- Check for cracking, bubbling, or detachment

- Replace rubber seals every 3–5 years depending on exposure

- Reapply liquid rubber annually or as needed

Environmental and Regulatory Factors

- PTFE is inert and FDA-compliant, but not biodegradable

- Rubber compounds can be eco-friendly if derived from sustainable sources

- Flex Seal liquid rubber formulations vary; low-VOC options are better for indoor use

Compliance with REACH, RoHS, and FDA standards will dictate which material you can legally use in certain industries.

Future Trends in Sealing Technology

- Nanocomposite PTFE seal rings: Even lower friction and wear

- Self-healing liquid rubbers: Automatically fill cracks or punctures

- Smart window seals: Embedded sensors to detect leaks or misalignment

These innovations promise to enhance both PTFE and rubber solutions in dynamic applications.

Final Verdict: PTFE vs. Rubber in Dynamic Sealing

Choosing between a PTFE seal ring, Flex Seal liquid rubber, and a rubber window seal isn’t just a technical decision—it’s a strategic one. Each material excels under specific conditions. If your system demands longevity under extreme pressure, temperature, or chemical exposure, PTFE is unbeatable. If your application needs flexible, quick sealing on irregular surfaces, rubber—especially liquid or molded—remains king.

Ultimately, the best choice depends on the motion, environment, and life expectancy of your seal. Dynamic sealing doesn’t tolerate shortcuts—so take the time to match the material to the mission.

With the right seal in place, your systems won’t just operate—they’ll excel.