In 2025, the global demand for efficient sealing solutions is surging—driven by increased automation, stricter leak-prevention regulations, and the growing complexity of machinery. For global distributors looking to stay competitive, offering the right pump shaft seal, durable diaphragm seals, and high-performance face seals is key to capturing market share and retaining loyal clients. This comprehensive guide helps distributors around the world understand what’s trending, how to build inventory strategically, and where to source the most in-demand mechanical seals. Know more..

Why Mechanical Seals Still Matter

While mechanical seal technology is not new, it remains essential in systems requiring fluid containment and motion transfer. From HVAC compressors to chemical reactors, sealing performance can determine safety, efficiency, and operating cost. Products like the pump shaft seal are fundamental to industrial pump longevity. Diaphragm seals are used in pressure-sensitive applications where accuracy and contamination control are crucial, while face seals play a key role in rotating equipment.

In 2025, global industries are demanding seals that are not only durable but also smart, customizable, and adaptable to more complex fluids and pressures.

Mechanical seals are critical to operational continuity. A leaking pump shaft seal could cause oil loss in heavy machinery, while faulty face seals in high-speed turbines can compromise entire production lines. That’s why mechanical seal sales remain a cornerstone for MRO (Maintenance, Repair, and Overhaul) distributors worldwide.

Top Mechanical Seal Types Distributors Should Stock

1. Pump Shaft Seal

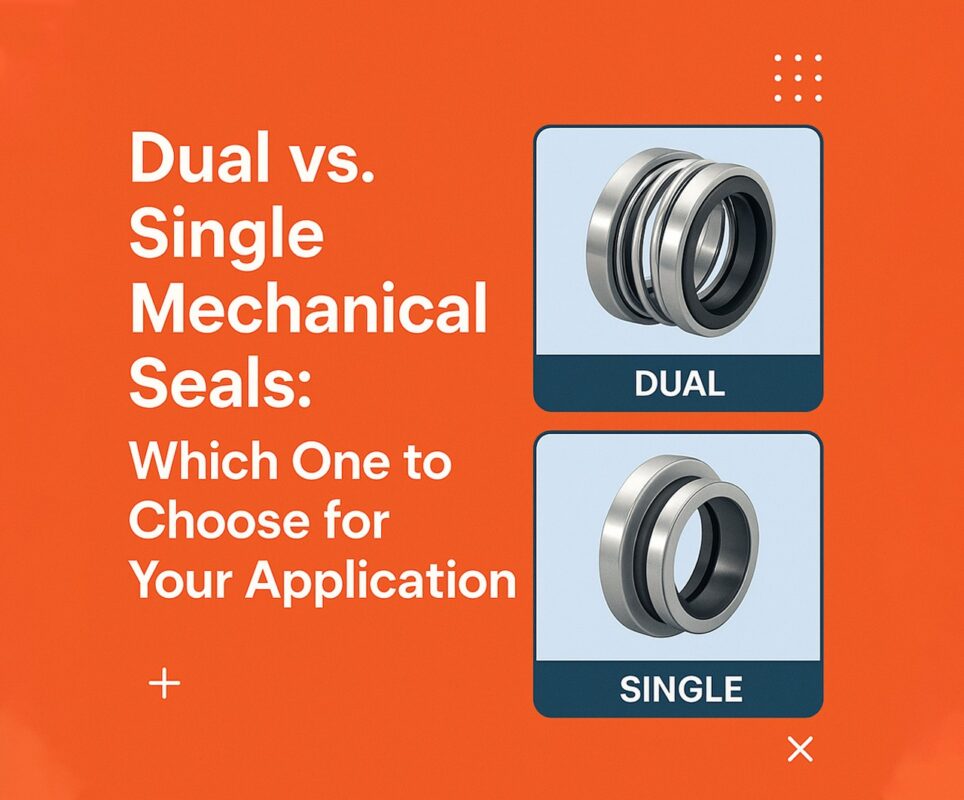

These seals are used in rotating equipment such as centrifugal pumps and mixers. In 2025, expect demand for cartridge-style, balanced, and dual pump shaft seal configurations to continue rising due to ease of installation and safety.

They’re typically made with a combination of elastomers, ceramics, and carbons to handle high-speed rotation, fluid pressures, and chemical compatibility. Popular industries: wastewater treatment, mining, agriculture, and chemical processing.

2. Diaphragm Seals

Common in chemical, pharmaceutical, and food sectors, diaphragm seals prevent fluid from contaminating pressure-sensing instruments. PTFE and metal-based variants are most in demand for their corrosion resistance. These seals also protect gauges, switches, and transmitters from vibration and clogging.

3. Face Seals

Sealing between rotating and stationary parts, face seals come in single, double, and tandem versions. Applications include agitators, high-speed compressors, and even military aerospace. Mechanical face seals are popular in hydraulic systems, engines, and axial flow machines.

Market Trends Distributors Must Know in 2025

Smart Sealing Technology

Seal manufacturers are now embedding sensors into pump shaft seal systems for condition monitoring—alerting users to potential leaks or friction anomalies. Real-time diagnostics are gaining traction in sectors like oil and gas, where downtime is extremely costly.

Eco-Friendly Materials

Expect increased interest in face seals and diaphragm seals made with biodegradable or recyclable materials. These are crucial in sustainability-focused regions like the EU and parts of Asia. New elastomers are being formulated to reduce carbon footprint and environmental impact.

Global Sourcing, Local Demand

Lead times and supply chain constraints are still top concerns. Distributors need to balance offshore sourcing with local inventory for quick turnaround, especially for mission-critical parts like the pump shaft seal. Strategic warehousing close to high-demand regions (e.g., Gulf Coast refineries or East Asian OEM hubs) ensures rapid fulfillment.

Modular Customization

Buyers want flexibility. Modular face seals that can be adapted to different bore sizes or diaphragm seals with replaceable membranes are in demand. Configurable SKUs help distributors reduce overstock and meet client-specific specs.

How to Choose the Right Seal Inventory

Evaluate Regional Industries

- Oil & Gas? Focus on corrosion-resistant pump shaft seal solutions.

- Pharma? Stock sterile, chemical-inert diaphragm seals.

- Aerospace? Carry precision face seals rated for extreme temperatures and vibration.

- Marine? Stock dual-balanced pump shaft seal options for submersible systems.

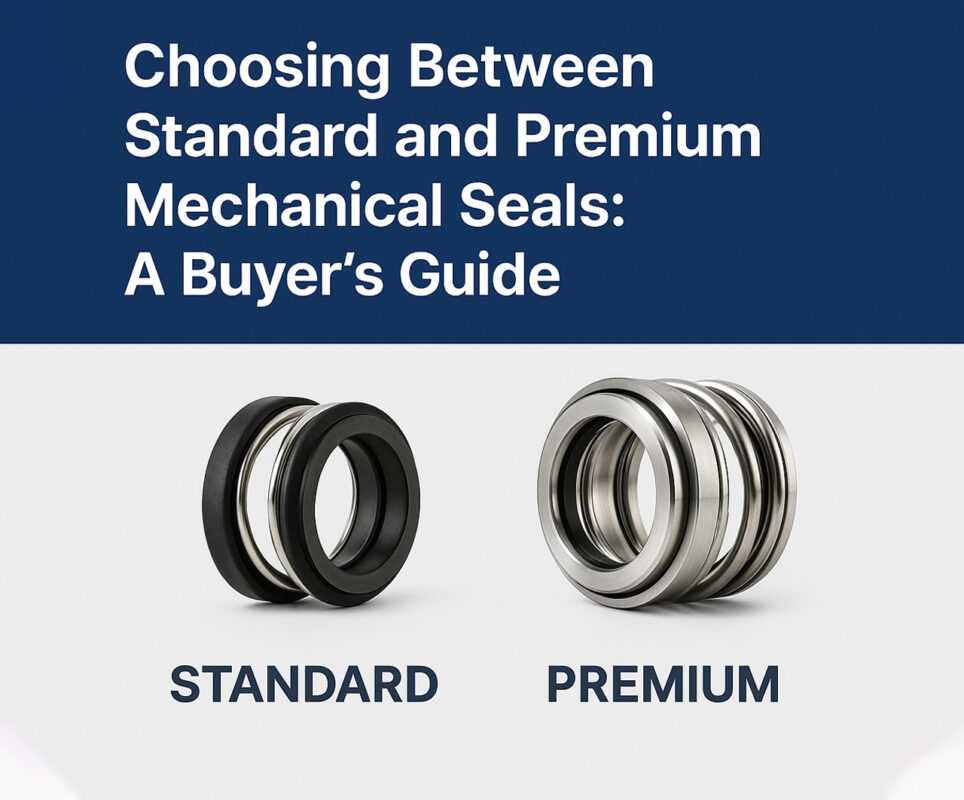

Analyze Replacement Frequency

Pump shaft seal parts typically need more frequent replacement in high-wear operations. Stock accordingly for faster turnover and repeat business. For industries using aggressive chemicals or operating continuously, carry premium-grade face seals with high MTBF ratings.

Keep Multiple Material Grades

For each seal type, carry options in Viton, PTFE, EPDM, FKM, and metal alloys to meet diverse fluid compatibility and pressure ratings. Keep track of changing regulations on material usage, especially for FDA or REACH-compliant components.

Offer Seal Kits

Create maintenance kits combining pump shaft seal, gaskets, and support rings. This boosts order size and supports preventive maintenance programs. Ensure packaging is user-friendly and labeled with part compatibility.

Working With Top Manufacturers

Partnering with reliable manufacturers helps you:

- Ensure consistent quality

- Get faster access to new tech (like smart seals)

- Offer private-label or white-label products

- Improve after-sales support and warranty handling

Key attributes to seek:

- Global certification (ISO, FDA, CE)

- Customization services

- Local distribution centers

- Real-time supply chain visibility

Whether it’s a standard face seal or a specialized diaphragm seal, having factory-direct access enhances your competitiveness and helps streamline your operations.

Selling Strategy: B2B Tips for Distributors

1. Educate Customers

Develop guides on choosing the right pump shaft seal or comparing face seals vs. traditional gaskets. Distributors who offer technical insight win more trust. Host webinars, create downloadable spec sheets, and use 3D visuals to simplify engineering decisions.

2. Bundle and Upsell

Package seals with installation tools, lubricants, and backup kits. Offer service plans for sectors that require frequent diaphragm seal replacement. Suggest OEM upgrade kits to boost long-term performance and reduce TCO (total cost of ownership).

3. Showcase Industry-Specific Case Studies

Use real-world examples where your pump shaft seal or face seals solved critical system failures. Clients remember performance. Include testimonials, maintenance savings data, or performance comparisons to bolster credibility.

4. Offer Value-Add Services

Consider on-site fitting, training, or predictive maintenance integration. These extras make your distribution business more than just a parts supplier. Use AR/VR for virtual troubleshooting and digital install support.

Online Presence: Seal Sales in the Digital World

2025 buyers expect instant access to technical data, certifications, and delivery tracking. Your e-commerce system should:

- Feature live stock levels of diaphragm seals, face seals, and pump shaft seal SKUs

- Offer CAD file downloads and seal calculators

- Include subscription reordering for consumables

- Allow for custom quoting and bulk order automation

Bonus: Invest in SEO to rank for long-tail keywords like “chemical-resistant pump shaft seal distributor” or “high-accuracy diaphragm seals for pharma.” Expand presence on B2B platforms like Alibaba, ThomasNet, and EU-based equivalents.

International Shipping and Compliance

Customs regulations, shipping delays, and certification mismatches can derail global distribution. Prepare by:

- Partnering with seal vendors who offer global compliance documentation

- Ensuring your face seals and pump shaft seal products meet RoHS, REACH, and local safety codes

- Using robust packaging to prevent transport damage to sensitive components

- Offering region-specific labeling and instructions (including multi-language inserts)

If you ship globally, be ready to provide digital proof of conformity for regulated industries such as food production, medical, and aerospace.

The Future of Mechanical Seals

Innovation in this space is accelerating. Look out for:

- AI-driven diagnostics in smart pump shaft seal systems

- 3D-printed diaphragm seals for on-demand replacement

- Face seal coatings that auto-heal under friction stress

- Self-lubricating elastomers to extend face seal service life

- Blockchain integration for seal traceability in supply chains

As mechanical seals become smarter and more integrated, global distributors must prepare to pivot from selling products to selling systems and insights.

Final Thoughts

Distributors who understand the evolving needs of global industries will thrive in 2025. By focusing on key components like the pump shaft seal, versatile diaphragm seals, and precision face seals, and by leveraging smart tech and eco-friendly options, you not only meet demand—you lead the market.

Position your catalog, optimize your digital presence, and align with top manufacturers to ensure you’re selling solutions—not just parts. Build strategic stock, educate your buyers, and integrate with industry-specific workflows. The future of sealing is here. Get ahead, stay stocked, and seal the deal.