In aerospace and defense applications, where reliability is non-negotiable and extreme environments are the norm, sealing technology must be exceptionally robust. Components like graphite seals, graphite seal ring, and graphite packing seal are increasingly relied upon in aircraft engines, spacecraft systems, and military hardware. These graphite-based seals offer unmatched thermal resistance, chemical stability, and mechanical strength—making them a top choice for high-performance sectors that operate under relentless pressure, with Graphite O Ring Seals being a critical component in ensuring system integrity.

This guide explores why graphite seals are revolutionizing aerospace and defense sealing solutions, how they’re used, and what makes them indispensable in critical mission applications. Know more..

Why Graphite Is the Go-To Material in Extreme Conditions

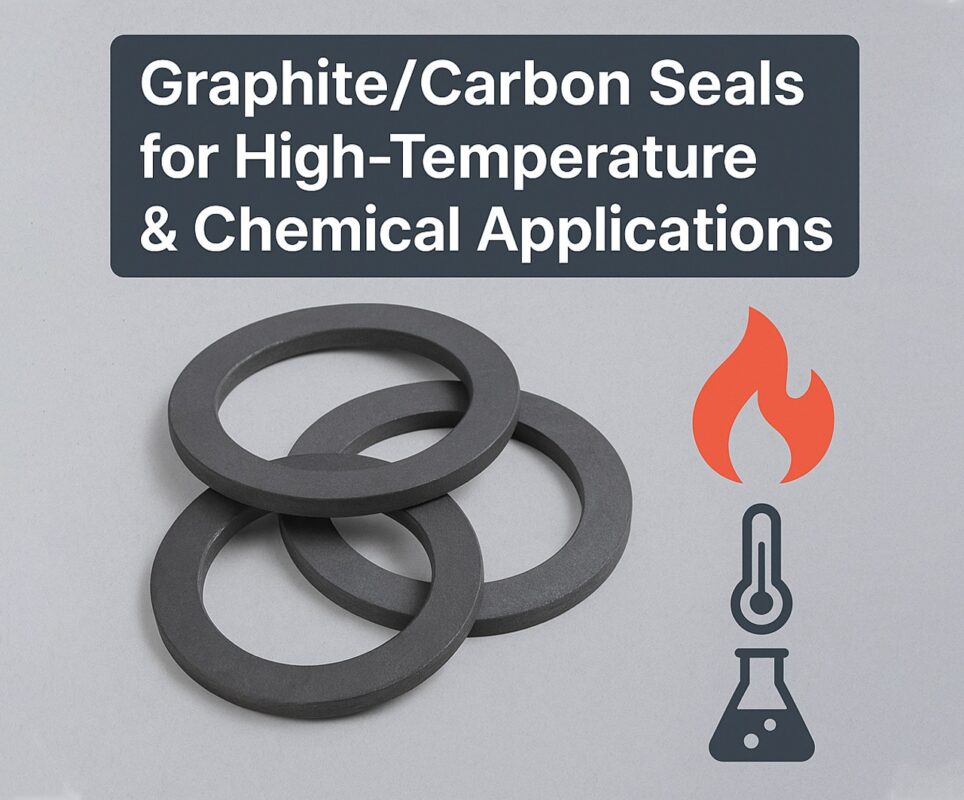

Graphite is a form of carbon known for its excellent thermal conductivity, lubricity, and resistance to extreme temperatures. It maintains structural integrity under severe conditions, including:

- High thermal gradients

- Corrosive chemical exposure

- Vacuum and high-pressure systems

These properties make the graphite o ring seal ideal for aerospace turbines and fuel systems, where thermal shock and rapid pressure changes are routine.

Unlike elastomeric seals that degrade above 250°C, graphite-based seals withstand temperatures exceeding 450°C (and even higher in some configurations). A graphite seal ring does not melt or soften, which prevents extrusion and failure in mission-critical systems.

Key Aerospace Applications for Graphite Seals

1. Jet and Rocket Engines

Combustion chambers and turbine shafts demand seals that can survive rapid thermal cycling. A graphite o ring seal offers low wear and high sealing integrity even when exposed to sudden changes from sub-zero to red-hot temperatures.

2. Cryogenic Fuel Systems

Spacecraft and high-altitude aircraft use cryogenic fuels that require materials resistant to extreme cold and chemical exposure. The compressibility and flexibility of the graphite packing seal make it suitable for low-temperature operation without cracking or shrinking.

3. Exhaust and Heat Shield Interfaces

Exhaust manifolds and shielding panels must be leak-proof under continuous vibration and thermal stress. A graphite seal ring handles both flex and friction without losing seal performance.

4. Military Hydraulic and Pneumatic Systems

Defense equipment often operates in deserts, arctic zones, or underwater. Graphite seals maintain function regardless of the environment, providing multi-theater reliability.

Comparing Graphite to Other Seal Materials

| Property | Graphite | PTFE | Nitrile | Viton |

| Max Temp (°C) | 450+ | 260 | 120 | 200 |

| Chemical Resistance | Excellent | Very good | Moderate | Good |

| Thermal Conductivity | High | Low | Low | Moderate |

| Reusability | High | Low | Low | Low |

| Compressibility | Adjustable | Medium | High | Medium |

Clearly, the graphite o ring seal outperforms in high-temp, high-pressure, and chemically aggressive settings.

Seal Types and Their Functions

Graphite O Ring Seal

Designed for dynamic or static joints, these rings are typically formed from compressed exfoliated graphite and can be reinforced with metallic cores for higher resilience. They’re used in rotating shafts, access panels, and vacuum chambers.

Graphite Seal Ring

These rigid seals are machined to exact tolerances and installed in valve stems, flanges, and pressure vessels. Their high structural integrity makes them ideal for shock and vibration-intensive environments like jet turbines.

Graphite Packing Seal

Often used in braided or molded form, this seal is common in valve glands and piston rods. Its self-lubricating nature reduces wear, while its flexibility ensures a tight fit in variable load conditions.

Key Benefits of Graphite Seals in Aerospace and Defense

1. Thermal Stability

Withstand drastic temperature changes without cracking, warping, or softening.

2. High Pressure Tolerance

Graphite seals maintain shape and function under pressures exceeding 5000 psi, depending on the configuration.

3. Chemical Resistance

Survive exposure to fuels, coolants, oxidizers, and hydraulic fluids.

4. Long Service Life

A properly installed graphite o ring seal or graphite packing seal can last longer than traditional elastomeric seals, reducing maintenance cycles.

5. Fire and Radiation Resistance

Graphite’s non-flammable and radiation-resistant properties make it ideal for space and combat use.

Challenges and Considerations

Despite their benefits, graphite seals come with certain handling and design considerations:

- Brittleness: Graphite is inherently brittle; improper installation can cause cracking.

- Custom Machining Required: Especially for the graphite seal ring, precision manufacturing is critical.

- Price Point: Cost is higher than rubber or plastic seals, though offset by extended lifespan and performance.

- Proper Surface Finish Needed: Graphite requires specific mating surface finishes to maximize sealing contact.

Manufacturing Innovations in 2025

Advancements in graphite processing and additive manufacturing have made the production of complex graphite seal ring geometries more efficient and accurate. Trends include:

- 3D-printed graphite composites

- Nanostructured coatings to enhance seal surface resilience

- Hybrid seals with metallic cores and graphite exteriors

These developments reduce lead time, improve tolerances, and enable rapid prototyping for custom defense systems.

Maintenance and Inspection Tips

- Visual Inspection: Look for signs of chipping, uneven wear, or compression set.

- Thermal Scanning: Use infrared imaging to detect hotspots that may indicate improper seal contact.

- Torque Checks: Ensure bolt or clamp loads haven’t relaxed due to gasket creep or thermal cycling.

- Scheduled Replacement: While graphite packing seal may last longer, set intervals should still be followed for safety-critical systems.

Pro tip: Always match replacement seals to OEM specifications and avoid generic substitutions in aerospace applications.

Supplier Checklist for Global Distributors

If you’re sourcing graphite o ring seal or graphite seal ring products for aerospace clients, prioritize vendors that:

- Have AS9100 or MIL-SPEC certifications

- Offer material traceability and batch testing

- Provide CAD files and 3D modeling support

- Supply heat-resistant and vacuum-rated options

Look for distributors who understand defense compliance and export control regulations, especially for ITAR-sensitive applications.

Case Study: Graphite Seals in Spacecraft Propulsion

A leading aerospace firm integrated graphite packing seal units into a next-generation liquid propulsion system. Compared to earlier PTFE-based seals, graphite versions:

- Withstood a 32% higher pressure cycle

- Maintained compression set over 1,000 hot/cold cycles

- Reduced maintenance costs by 40% over a 2-year mission window

Result: Increased propulsion system reliability and mission uptime with zero recorded leak failures.

Future Outlook: Graphite Seals Beyond 2025

As aerospace systems become more autonomous and mission durations extend, the role of self-monitoring, high-endurance seals will expand. Innovations to watch:

- AI-integrated graphite seals that log usage data and wear metrics

- Graphene-infused graphite o ring seal compounds for enhanced strength

- Space-hardened graphite seal ring designs for lunar and Mars missions

With increasing demand from private spaceflight and hypersonic military aircraft, graphite sealing technology is set to become even more vital in the coming decade.

Final Thoughts

In aerospace and defense systems where the stakes are sky-high—literally—every seal matters. Components like the graphite o ring seal, graphite seal ring, and graphite packing seal prove their worth by performing where others fail. Their ability to handle thermal extremes, high pressure, and chemical aggression ensures they’ll remain indispensable across aircraft, spacecraft, and military-grade machinery.

For engineers, MRO teams, and defense contractors, upgrading to graphite-based sealing solutions is not just about better performance—it’s about mission assurance. When you need a seal that works under fire, in a vacuum, or on the edge of space, graphite gets the job done.

Stay ahead of the curve. Specify graphite. Seal with confidence.