In the world of hydraulic systems and linear actuators, controlling motion with stability and precision is everything. Whether you’re working with heavy machinery, aerospace actuators, or industrial robotics, the right components ensure smooth operation, extended service life, and system reliability. Among the most important motion-guiding components are wearrings, guide tape, and the traditional wear ring. But which of these actually offers better stability in motion?

In this article, we explore the differences between guide tape and wearrings, including the versatile wear ring, analyzing their use cases, performance characteristics, and long-term benefits. Whether you’re designing a new system or upgrading an existing one, understanding the subtle but critical differences between these two options will help you make the right decision. Know more..

What Are Wear Rings and Guide Tape?

Wear Ring (aka Wearrings)

A wear ring, often referred to in plural as wearrings, is a rigid ring typically made from materials like PTFE composites, phenolic resin, or thermoplastics. Installed in hydraulic or pneumatic cylinders, it guides the piston or rod, preventing metal-to-metal contact and absorbing lateral loads.

Guide Tape

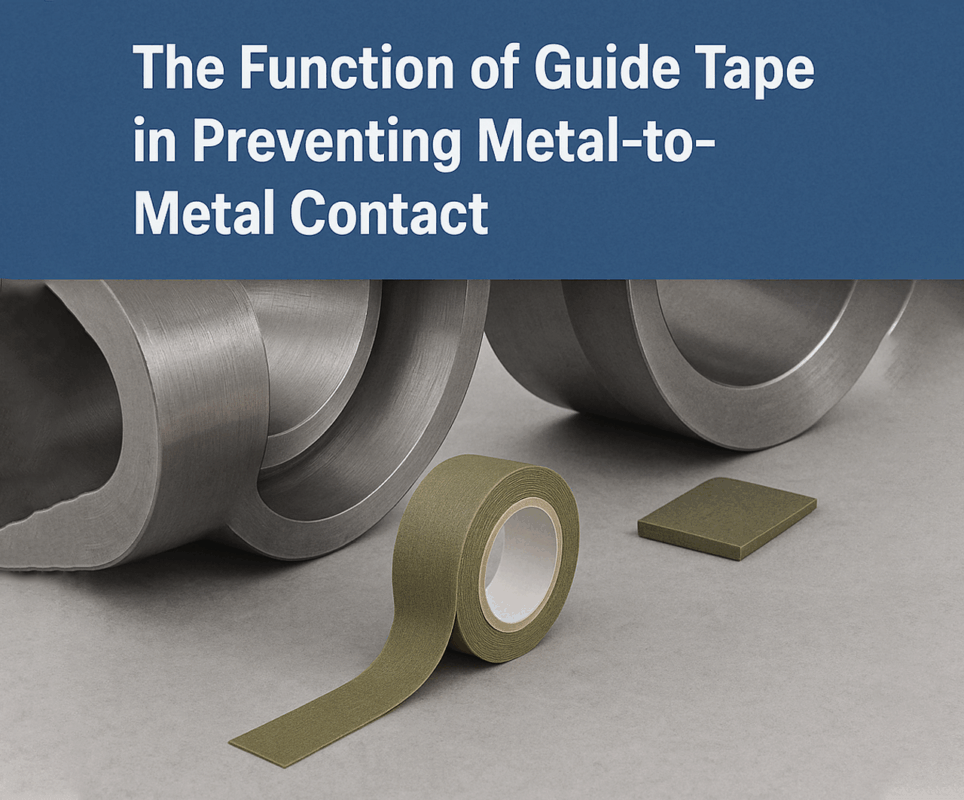

Guide tape, also known as PTFE guide strip, serves a similar purpose but comes in a flat tape format instead of a solid ring. It’s usually cut to size and wrapped around pistons or rods to reduce friction and wear, guiding motion along a fixed axis.

Shared Purpose, Different Designs

While both guide tape and wearrings (or wear ring) serve to guide motion and prevent direct contact between moving metal components, their form factor significantly impacts how they’re used.

Key Similarities:

- Prevent scoring or galling of cylinder walls

- Stabilize the piston or rod during actuation

- Extend seal and system life

- Made from similar low-friction, high-durability materials

Key Differences:

| Feature | Wear Ring (Wearrings) | Guide Tape |

| Form | Solid ring | Flat tape |

| Installation | Drop-in groove fit | Cut-to-length, wrapped |

| Load-bearing ability | High | Moderate |

| Flexibility | Low | High |

| Precision tolerance | Excellent | Good |

Where Guide Tape Excels

Guide tape is ideal for applications where flexibility, custom sizing, and low inertia are required. It offers lightweight, quick-to-install solutions for both new builds and repair projects.

Advantages of Guide Tape:

- Custom fit: Can be cut to exact size, ideal for non-standard bore diameters.

- Reduced inventory: One roll of guide tape can service multiple sizes.

- Lightweight: Adds minimal weight to moving parts.

- Low cost: Generally cheaper than machined wearrings.

Ideal Applications:

- Pneumatic cylinders

- Compact actuators

- Lightweight or portable devices

- Prototypes or field repairs

Because guide tape is extremely versatile and easy to work with, it’s especially popular in systems where space is tight or rapid prototyping is essential.

Where Wearrings (Wear Rings) Dominate

For heavy-duty performance, wearrings (or wear rings) provide more consistent support and higher load capacity. These rings are precision-machined for exact fits, making them the go-to for high-pressure hydraulic systems and heavy-duty actuators.

Advantages of Wearrings:

- High load-bearing: Superior lateral load absorption.

- Precise alignment: Tight manufacturing tolerances ensure stable motion.

- Thermal stability: Better at resisting deformation in high-temperature environments.

- Long life: More durable under extreme conditions.

Ideal Applications:

- Hydraulic cylinders in construction equipment

- Aerospace actuators

- Presses and heavy machinery

- Oil & gas applications

If system failure is not an option, the rigid structure of a wear ring is usually the better choice.

Performance Comparison in Real-World Conditions

Let’s break down how each performs under various stressors:

1. Load Conditions

- Wearrings are better for high loads and impact scenarios.

- Guide tape can deform under heavy pressure, especially if improperly cut or installed.

2. Speed

- Guide tape performs well at medium-to-high speeds due to lower friction.

- Wear rings may generate slightly more heat at high speeds but offer better tracking.

3. Temperature

- Wear ring materials can handle broader temperature swings.

- Guide tape may soften or shrink in extreme temperatures.

4. Contamination Tolerance

- Guide tape may allow particles to slip underneath if installation isn’t perfect.

- Wearrings create a more complete seal path, reducing ingress.

Creative Use Cases for Guide Tape

Guide tape is increasingly used in emerging industries due to its adaptability:

- Medical Devices: Lightweight and inert, ideal for non-magnetic or sterilizable systems.

- 3D Printing: Used in low-friction sliding rails for print heads.

- Robotics: Compact actuators benefit from space-saving, precision guide tape layers.

It also works well in cost-conscious environments or for short lifecycle products where replacement is expected and acceptable.

Emerging Technologies in Wear Rings

Modern wearrings are evolving with new materials and features:

Composite Materials

Advanced PTFE-graphite, carbon-fiber blends, and reinforced phenolics allow wear rings to function longer and under harsher conditions.

Smart Wear Monitoring

Some next-gen wear ring designs include embedded wear indicators or sensors that alert operators when it’s time for replacement.

Low-Friction Coatings

Manufacturers are now offering wearrings with self-lubricating coatings, reducing startup friction and extending seal life.

If you’re working with a forward-thinking supplier, custom wear ring solutions may now include design enhancements previously reserved for full hydraulic systems.

Choosing the Right Option: Guide Tape or Wear Ring?

Ultimately, the right choice between guide tape and wearrings depends on your application, budget, and performance priorities.

Choose Guide Tape if:

- You need flexible sizing or quick installation

- The system operates under moderate loads

- Weight savings and low cost are essential

- You’re designing compact or portable machinery

Choose Wearrings if:

- The system faces high side loads or pressure

- Precision alignment is critical

- Long-term durability matters

- You’re operating in extreme environments

Common Mistakes to Avoid

❌ Misjudging Load Requirements

Installing guide tape in a high-load hydraulic cylinder may result in rapid wear or system instability. Always assess lateral loads carefully.

❌ Poor Installation

Unevenly cut guide tape or poorly seated wearrings can create misalignment, leading to premature seal failure.

❌ Ignoring Thermal Expansion

Both guide tape and wearrings can expand or shrink depending on temperature. Consider material compatibility with the operating range.

Tips for Optimal Stability

- Match materials: Use compatible materials for seals, rings, and lubricants.

- Use backup rings: When needed, combine wearrings with support components to reduce deflection.

- Inspect regularly: Both guide tape and wear ring components should be checked during every maintenance cycle.

Final Thoughts

When it comes to stability in motion, both guide tape and wearrings offer unique advantages. A wear ring delivers unmatched strength and alignment for heavy-duty systems, while guide tape provides flexibility and ease for lightweight or compact applications. The choice isn’t just about cost—it’s about engineering the right motion control for your system’s demands.

As automation and precision machinery continue to evolve, so too will the materials and design innovations behind wearrings, guide tape, and every wear ring solution. By understanding the strengths and trade-offs of each, you can build systems that move better, last longer, and perform consistently under pressure.