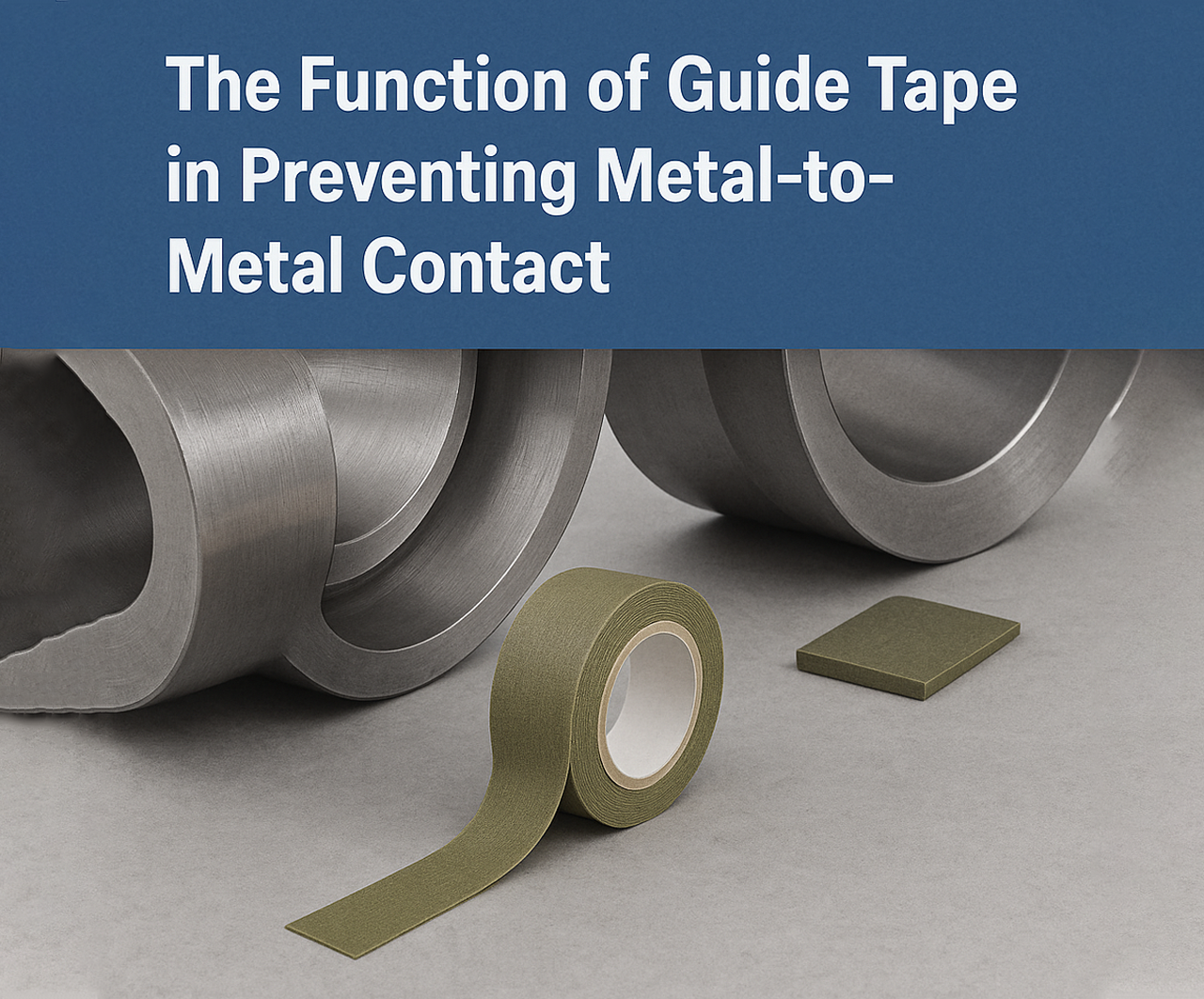

In precision engineering, whether in sewing machinery, industrial equipment, or delicate assembly systems, one overlooked hero plays a major role in ensuring smooth operation—seam guide tape for sewing machine, seam guide tape, and the versatile 1 4 inch seam guide tape. These tapes may appear simple, but their role in controlling alignment, eliminating friction, and protecting critical components from metal-to-metal contact is more crucial than ever. When components repeatedly move or vibrate against each other, wear is inevitable unless a protective buffer is in place. That’s where guide tapes come in.

Let’s take a closer look at how seam guide tapes function, where they’re used beyond sewing machines, and how their simple yet effective design contributes to equipment longevity and operational consistency. Know more..

What Is Seam Guide Tape?

Seam guide tape is a durable, adhesive-backed material designed to align components and reduce abrasion during repeated motion. While it’s widely recognized in textile machinery—especially as seam guide tape for sewing machines—its application in industrial sectors is expanding rapidly.

At its core, seam guide tape provides:

- Precision alignment

- Reduced vibration and friction

- A buffer zone that minimizes metal-on-metal wear

- A clear visual line for accuracy (especially in sewing applications)

1 4 inch seam guide tape, in particular, is valued for its compact width, making it ideal for tight spaces, small devices, and precision-guided equipment.

Why Preventing Metal-to-Metal Contact Matters

Metal-on-metal contact is a major contributor to equipment degradation. When surfaces rub directly against each other:

- Heat builds up from friction

- Surfaces wear and score

- Precision is lost due to dimensional changes

- Corrosion and galling occur over time

Guide tape mitigates all of these risks by serving as a wear-resistant buffer. It can be quickly applied to shafts, rails, or platforms where motion is expected but clearance is minimal.

How Seam Guide Tape Works Mechanically

When placed on a moving or vibrating surface, seam guide tape creates a low-friction layer between contacting parts. This helps in:

- Distributing load evenly

- Reducing point pressure

- Avoiding deformation of sensitive components

- Allowing controlled movement along an axis

In industrial assembly lines or robotics, this function keeps linear guides and automated arms in top condition. In sewing machines, seam guide tape for sewing machine helps guide fabric evenly without shifting, fraying, or misalignment.

Applications of Guide Tape Across Industries

1. Sewing and Garment Manufacturing

Guide tape is commonly used on throat plates, presser feet, or machine beds. The 1 4 inch seam guide tape acts as a visual and tactile guide, helping operators maintain consistent seam allowances without marking the fabric.

2. CNC and Robotics

Tape is applied to sliders and rails where robotic arms or gantries must move with minimal resistance. It also cushions high-frequency vibrations.

3. Medical Device Assembly

In micro-manufacturing environments, seam guide tape helps stabilize components during gluing, soldering, or UV bonding.

4. Automotive Interior Assembly

During dashboard or door panel fitting, guide tape prevents metal brackets from contacting trim or painted parts during assembly.

5. 3D Printing Platforms

Used as a surface buffer to align build plates and guide calibration tools.

Benefits of Using Seam Guide Tape

- Precision Control Especially in applications like 1 4 inch seam guide tape, the narrow format ensures detailed guidance on compact surfaces.

- Reduced Maintenance By preventing direct wear, guide tapes extend the lifespan of components like feed dogs, presser feet, or sliding assemblies.

- Cost-Effective Protection Compared to metal shims, bushings, or custom coatings, seam guide tape is an inexpensive, easy-to-install alternative.

- Quick Installation and Replacement Most tapes have peel-and-stick adhesive backings. Replacing a worn section takes seconds, not hours.

- Noise Reduction Tape acts as a damper, reducing clatter in high-speed machinery.

Material Considerations

Guide tapes are made from a variety of materials, chosen based on the required application.

| Material Type | Benefits |

| PTFE (Teflon) | Low friction, chemical-resistant |

| Nylon | Abrasion-resistant, flexible |

| Polyester | Low cost, smooth glide |

| Silicone-backed | Heat-resistant, high adhesion |

For seam guide tape for sewing machines, PTFE is popular for its smooth glide, helping fabric feed evenly without snagging.

Sizing and Selection Guide

Selecting the right tape depends on:

- Width requirements: For tight control, 1 4 inch seam guide tape is ideal.

- Operating temperature: Choose materials that won’t degrade under heat.

- Surface adhesion: Some surfaces (like aluminum or stainless steel) may require specific adhesives.

- Wear frequency: For high-usage areas, opt for fabric-reinforced or PTFE tape.

Installing Seam Guide Tape: Best Practices

- Clean the Surface Thoroughly Oil, dust, or lint reduces adhesion.

- Use a Straight Edge for Alignment Especially for long runs or precision seams.

- Avoid Stretching the Tape Apply it evenly to maintain shape and adhesion.

- Check for Bubbles or Gaps Air pockets can lead to uneven contact and early failure.

- Press Firmly and Allow Adhesive to Cure Give it time before placing the machine or part into operation.

When to Replace Your Guide Tape

Even the best seam guide tape wears over time. Replace it when:

- Surface becomes glossy or slick (loss of grip)

- Tape begins to peel or bubble

- You see residue or buildup on machinery

- Fabric starts pulling or shifting unexpectedly

Routine checks—especially in production environments—can save hours in troubleshooting.

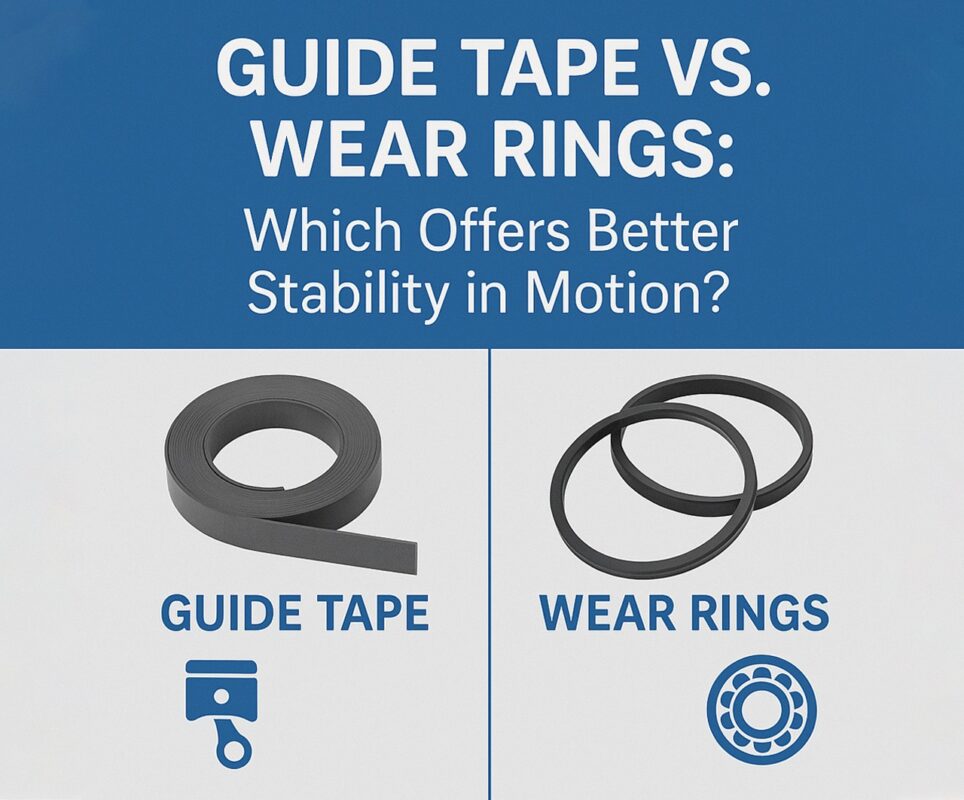

Alternatives and Complementary Products

While seam guide tape for sewing machines is a go-to for many, other formats include:

- Magnetic seam guides: Reusable but bulkier

- Clip-on seam allowances: Great for temporary projects

- Laser alignment tools: High-tech, but costly

In industrial settings, guide rails, linear bearings, and gibs may also be used, though they lack the flexible utility of seam tape in tight applications.

Environmental Impact and Sustainability

Some manufacturers are now offering eco-friendly versions of 1 4 inch seam guide tape using biodegradable adhesives and recyclable film. If sustainability matters in your production process, these options may align with your values and compliance needs.

Case Study: High-Speed Sewing Line Efficiency Boost

A textile company was experiencing inconsistency in seam alignment during high-speed stitching. After replacing traditional seam markings with PTFE-based 1 4 inch seam guide tape, the results were clear:

- Reduced seam deviation by 40%

- Minimized fabric damage

- Operator fatigue decreased thanks to visual alignment

This simple upgrade saved over $20,000 annually in rework and material waste.

Final Thoughts: Small Tape, Major Impact

From industrial assembly to creative textile work, seam guide tape, seam guide tape for sewing machine, and especially 1 4 inch seam guide tape serve a bigger purpose than meets the eye. They prevent metal-on-metal contact, reduce vibration, enhance precision, and extend the life of expensive machinery.

Whether you’re sewing a straight line or aligning robotic arms, the humble guide tape offers low-cost insurance against wear, misalignment, and costly repairs. When every micron matters, a quarter-inch of tape might just make all the difference.