When it comes to preventing leaks and enhancing equipment longevity in pumping systems, mechanical seals have long surpassed traditional mechanical packing solutions. Among the most trusted and widely used are the M3N and H7N mechanical seals — high-performance options that strike a balance between affordability, resilience, and broad industrial compatibility. For engineers sourcing from top mechanical pump seals suppliers or transitioning from legacy sealing solutions to more modern technologies like the metal bellow mechanical seal, these two models are indispensable in a range of sectors.

In this comprehensive article, we explore why M3N and H7N seals continue to be industry standards, what makes them uniquely versatile, and how they compare to both classic and advanced sealing technologies. Know more..

From Mechanical Packing to Mechanical Seals: A Performance Evolution

The move from mechanical packing to mechanical seals like the M3N and H7N has been driven by demands for greater reliability, lower maintenance, and improved energy efficiency. Packing materials are inexpensive, but they wear quickly, require regular tightening, and can result in excessive leakage — especially under high-speed or high-pressure conditions.

In contrast, mechanical seals such as the M3N and H7N offer:

- Leak-free performance

- Long service life

- Better protection against contamination

- Reduced energy consumption due to less friction

That’s why more buyers working with mechanical pump seals suppliers are steering clear of packing and instead turning toward standardized, high-performance mechanical seal configurations.

Understanding the M3N Mechanical Seal

Design Highlights:

- Balanced, single-spring rotary seal

- Stationary seat design (typically Q1Q1 or Q1U2 combo)

- Suitable for unidirectional or bidirectional rotation

Material Options:

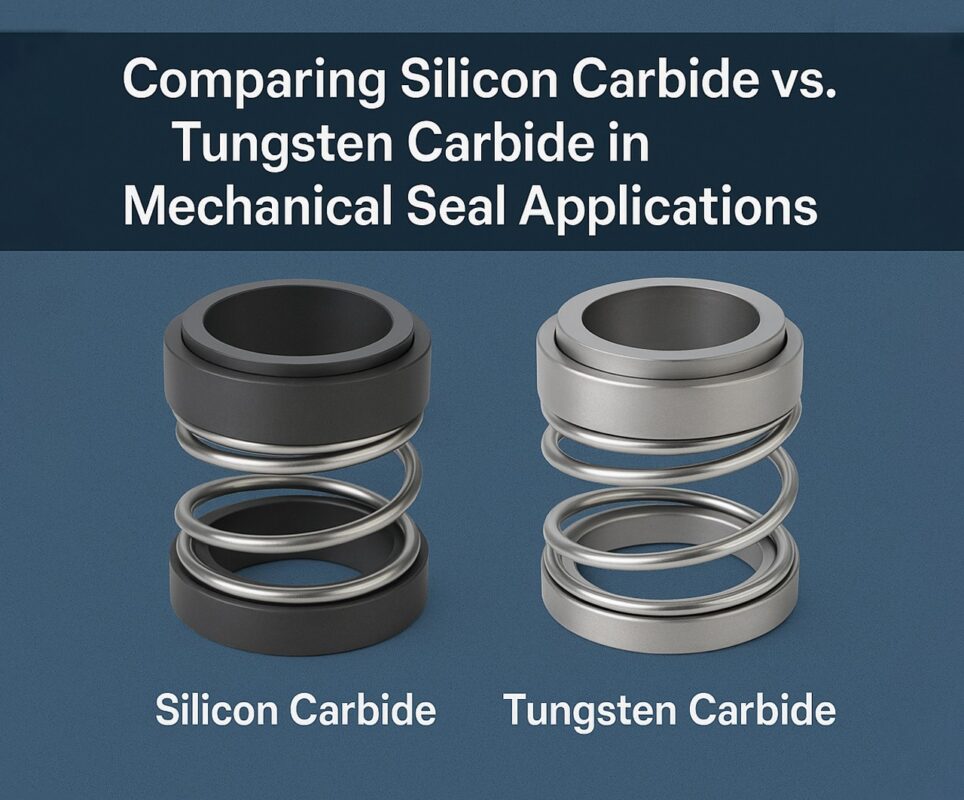

- Seal faces: Carbon, Silicon Carbide, Tungsten Carbide

- Elastomers: EPDM, FKM (Viton), NBR

- Springs: Stainless Steel (SS304 or SS316)

Applications:

- Water and wastewater pumps

- Light chemical handling

- HVAC and building systems

M3N seals are valued for their adaptability. Unlike the metal bellow mechanical seal, which is often used in high-temp or caustic environments, the M3N is more of a generalist — making it a staple in commercial and municipal systems.

Delving into the H7N Mechanical Seal

Design Features:

- Heavy-duty, multi-spring, balanced mechanical seal

- Cartridge and component designs available

- Stationary design for improved thermal handling

Material Combinations:

- Faces: Silicon Carbide vs. Tungsten Carbide

- Secondary Seals: Chemically resistant elastomers

- Metal Parts: Stainless steel or high-nickel alloys

Application Range:

- Oil and gas

- Food and beverage

- Chemical processing

For buyers considering metal bellow mechanical seal options but not needing their full temperature resistance, the H7N provides an ideal intermediate choice — excellent for high-duty cycles, pressure variations, and moderate thermal fluctuations.

Why These Seals Are Industry Favorites

1. Global Availability

Top mechanical pump seals suppliers around the world stock M3N and H7N due to their compatibility with major pump brands like Grundfos, KSB, Wilo, and others.

2. Easy Retrofit Design

They can replace dozens of OEM-specific seals with minimal modification, which makes them popular in aftermarket scenarios.

3. Cost-Effective Maintenance

Unlike mechanical packing, which demands constant adjustment, both M3N and H7N seals require little attention post-installation.

4. Broad Chemical Compatibility

Using FKM or PTFE materials, these seals handle a variety of chemicals, from alkaline solutions to light hydrocarbons.

5. Performance Under Pressure

H7N in particular can operate reliably in systems with pressures exceeding 25 bar, making it ideal for multistage pumps and pressure boosters.

Comparing M3N, H7N, and Metal Bellow Mechanical Seal Options

| Feature | M3N | H7N | Metal Bellow Mechanical Seal |

| Rotation Direction | Uni/Bi-directional | Bi-directional | Bi-directional |

| Pressure Range | Up to 10 bar | Up to 25 bar | Up to 35+ bar |

| Temperature Tolerance | Up to 120°C | Up to 180°C | Up to 300°C |

| Chemical Resistance | Moderate | High | Excellent |

| Ideal For | Water, HVAC | Oil, chemicals | Extreme temperature/chemicals |

Although metal bellow mechanical seals offer top-tier performance in aggressive environments, M3N and H7N seals remain the workhorses in applications that don’t warrant such advanced specifications.

Case Study: Municipal Water Facility

A city-owned water treatment facility in Germany transitioned from mechanical packing to M3N seals across 14 pump stations. The result:

- 90% reduction in water loss

- 65% decrease in maintenance hours

- Annual energy savings of $12,000

This is a textbook example of how a properly selected M3N seal — sourced from a reliable mechanical pump seals supplier — can provide substantial ROI within a year.

Case Study: Chemical Transfer Pump

A medium-sized chemical plant in Southeast Asia upgraded their rotary lobe pump seals to H7N units, replacing inconsistent aftermarket brands. Benefits included:

- Greater uptime under caustic fluid exposure

- Longer MTBF (Mean Time Between Failure)

- Improved operator safety

The plant initially considered metal bellow mechanical seals but opted for H7N due to lower cost and sufficient chemical resistance.

Selection Tips for Engineers

- Understand Your Media

- Corrosive fluids? High temperature? Dirty slurries?

- Evaluate Operating Parameters

- RPM, pressure, direction of rotation, and installation space

- Work With Trusted Mechanical Pump Seals Suppliers

- Avoid no-name brands; rely on suppliers offering application support

- Consider Future-Proofing

- Is it worth stepping up to an H7N now to avoid problems later?

Maintenance Best Practices

- Always check shaft and sleeve condition before installation

- Use OEM-recommended torque and compression settings

- Replace O-rings with every seal change, even if they look fine

- Use compatible lubricants during installation

M3N and H7N seals are easy to install, especially when pre-assembled as cartridge units. However, poor installation remains a leading cause of failure, second only to sourcing from unqualified mechanical pump seals suppliers.

Final Thoughts

Whether you’re upgrading from mechanical packing, maintaining a fleet of centrifugal pumps, or specifying new systems, M3N and H7N mechanical seals remain top performers across industries. Their balance of cost, durability, and ease of sourcing from reputable mechanical pump seals suppliers makes them a smart choice for both OEMs and maintenance teams.

And while metal bellow mechanical seals have their place in extreme environments, M3N and H7N are more than capable of handling the demands of 90% of industrial sealing applications.