When equipment starts leaking hydraulic fluid, it’s often a signal that something critical has gone wrong with your hydraulic cylinder seal kits, a failed hydraulic oil seals, or a defect in the material supplied by certain hydraulic seals manufacturers. Seals are small, but they’re at the heart of hydraulic integrity. Their failure not only leads to downtime and contamination but also presents safety and environmental hazards. This guide explores the most common causes of hydraulic seal leaks, early signs of failure, and expert prevention and repair strategies to keep your systems leak-free. Know more..

Understanding Hydraulic Seal Function

A hydraulic oil seal prevents fluid from escaping the pressurized chamber of a cylinder while blocking contaminants from entering. Seals in hydraulic cylinder seal kits include rod seals, piston seals, wipers, and wear rings—each with a specific role.

Quality hydraulic seals manufacturers design their seals to withstand high pressures, varying temperatures, and mechanical wear. But even the best seals degrade over time or under the wrong operating conditions.

Symptoms of a Leaking Hydraulic Seal

- Visible Fluid Leaks If you notice oil leaking from the cylinder rod or base, your hydraulic oil seal is likely worn, nicked, or misaligned.

- Inconsistent Pressure Fluctuations or a drop in system pressure usually means fluid is bypassing an internal seal.

- Noisy Cylinder Operation Screeching, popping, or rattling may indicate a worn rod seal or contaminants affecting seal integrity.

- Excessive Heat Buildup A leaking seal can cause the pump to work harder, leading to overheating and premature wear.

- Jerky or Lagging Cylinder Motion Damaged hydraulic cylinder seal kits can allow air ingress, causing uneven or delayed movement.

Root Causes of Seal Leakage

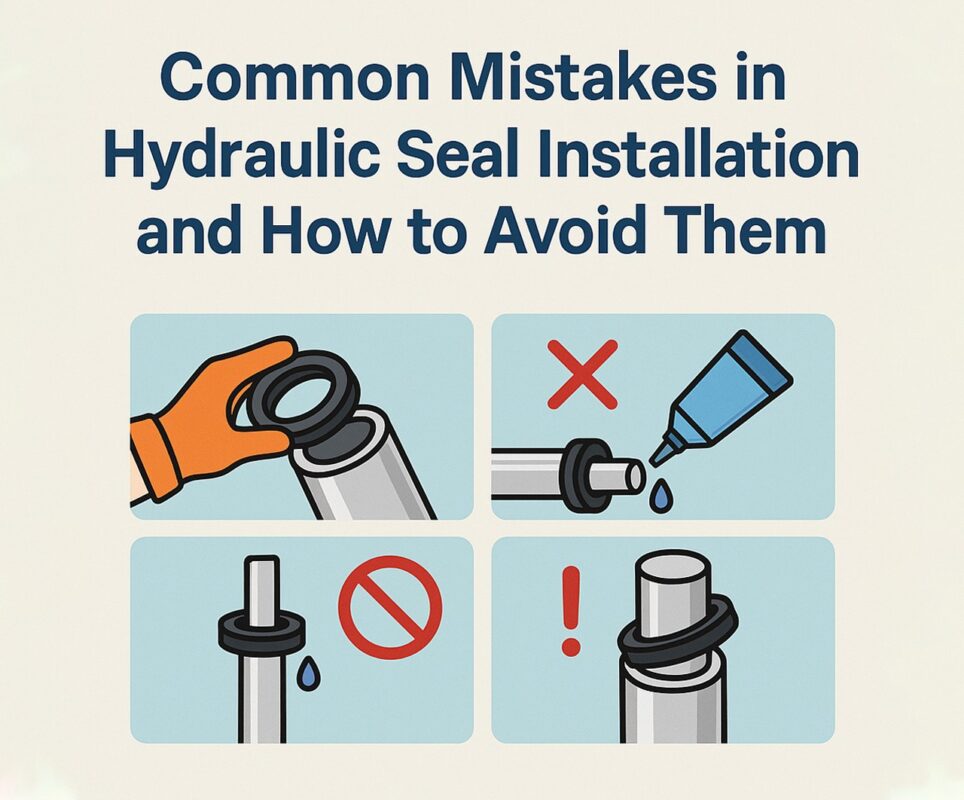

1. Improper Installation

Misaligned or over-tightened seals cause premature wear. Even top-tier seals from trusted hydraulic seals manufacturers can fail if installed incorrectly.

2. Contaminated Fluid

Dirt, metal shavings, or water in the fluid scratches seal surfaces, breaks down lubricants, and erodes materials.

3. Thermal Degradation

Excessive heat hardens elastomeric materials, causing cracks and loss of elasticity in your hydraulic oil seal.

4. Pressure Spikes

Overpressurization forces seals beyond their design limits, leading to blowouts or extrusion into the cylinder’s gaps.

5. Incompatible Seal Material

Not all seals are compatible with every hydraulic fluid. Some hydraulic cylinder seal kits may degrade faster in synthetic or fire-resistant oils.

6. Shaft or Bore Damage

Scored or pitted surfaces can slice into seals or leave gaps for leaks to form.

Common Mistakes to Avoid

- Using general-purpose seals instead of pressure-rated options from professional hydraulic seals manufacturers

- Replacing only the leaking seal instead of the entire hydraulic cylinder seal kit

- Failing to inspect rod or bore condition before installing new seals

- Ignoring OEM clearance tolerances

Troubleshooting by Symptom

| Symptom | Probable Cause | Recommended Action |

| Fluid leaks at rod | Worn or brittle hydraulic oil seal | Replace with new OEM-rated seal |

| Pressure drop in system | Internal bypass due to damaged piston seal | Rebuild cylinder with full hydraulic cylinder seal kit |

| Heat buildup | Friction from incorrect seal fit or dry installation | Review installation and replace damaged seals |

| Jerky motion | Air ingress through damaged rod wiper | Inspect and replace wiper and secondary seal |

Choosing the Right Replacement Seals

Not all seals are equal. When selecting replacements:

- Match fluid compatibility (mineral, bio, synthetic)

- Confirm pressure ratings and tolerance specs

- Choose from reputable hydraulic seals manufacturers with a proven track record

Materials to consider:

- NBR (Nitrile): Good for general oil-based fluids

- FKM (Viton): Excellent for high-temperature or aggressive fluids

- PU (Polyurethane): Durable and wear-resistant

Best Practices to Prevent Future Leaks

1. Regular Fluid Analysis

Contaminants lead to premature hydraulic oil seal failure. Analyze fluid quarterly to detect wear particles, moisture, or acid buildup.

2. Cylinder Alignment Checks

Rod misalignment adds side load on seals. Perform routine laser alignment to ensure straight motion and uniform wear.

3. Use Complete Hydraulic Cylinder Seal Kits

Mixing old and new seals results in uneven wear. Always replace full kits during rebuilds.

4. Install Proper Wipers

Wipers protect rod seals from dust, mud, and debris. Don’t skip this critical component.

5. Partner with Trusted Suppliers

Work only with hydraulic seals manufacturers who offer technical support, material data sheets, and product warranties.

When to Rebuild vs. Replace the Cylinder

- Rebuild if: Rod and bore are in good shape, and full hydraulic cylinder seal kits are available.

- Replace if: Cylinder body is cracked, heavily scored, or worn beyond tolerance.

Consult your equipment’s OEM guidelines or a certified hydraulic technician before making the call.

Pro Tip: Smart Seal Monitoring

Modern industrial systems integrate sensors to monitor:

- Fluid pressure

- Seal temperature

- Vibration

By embedding sensors near your hydraulic oil seal, you gain insight into wear trends and predict failures before they occur.

Tools That Make Troubleshooting Easier

- Seal Pick Sets: Remove old seals without damaging housing

- Digital Calipers: Verify seal groove dimensions

- UV Leak Detection Kits: Identify invisible fluid seepage

- Pressure Gauges: Diagnose internal bypass or overload

Recommended Inspection Schedule

| Interval | Task |

| Monthly | Check for visible leaks, inspect rods and wipers |

| Quarterly | Perform fluid analysis, test system pressure |

| Annually | Replace wipers and minor hydraulic oil seal elements, inspect bore condition |

| Biannually | Full teardown and replacement with new hydraulic cylinder seal kits |

Final Thoughts

Hydraulic seal leaks are more than just messy—they’re a sign your system is under strain. Whether it’s due to a worn hydraulic oil seal, an outdated set of hydraulic cylinder seal kits, or low-quality materials from questionable hydraulic seals manufacturers, ignoring seal issues can cause major operational setbacks.

Prevention starts with inspection, high-quality components, and correct installation. Make seal health part of your proactive maintenance plan—and keep downtime, cost, and risk to a minimum.