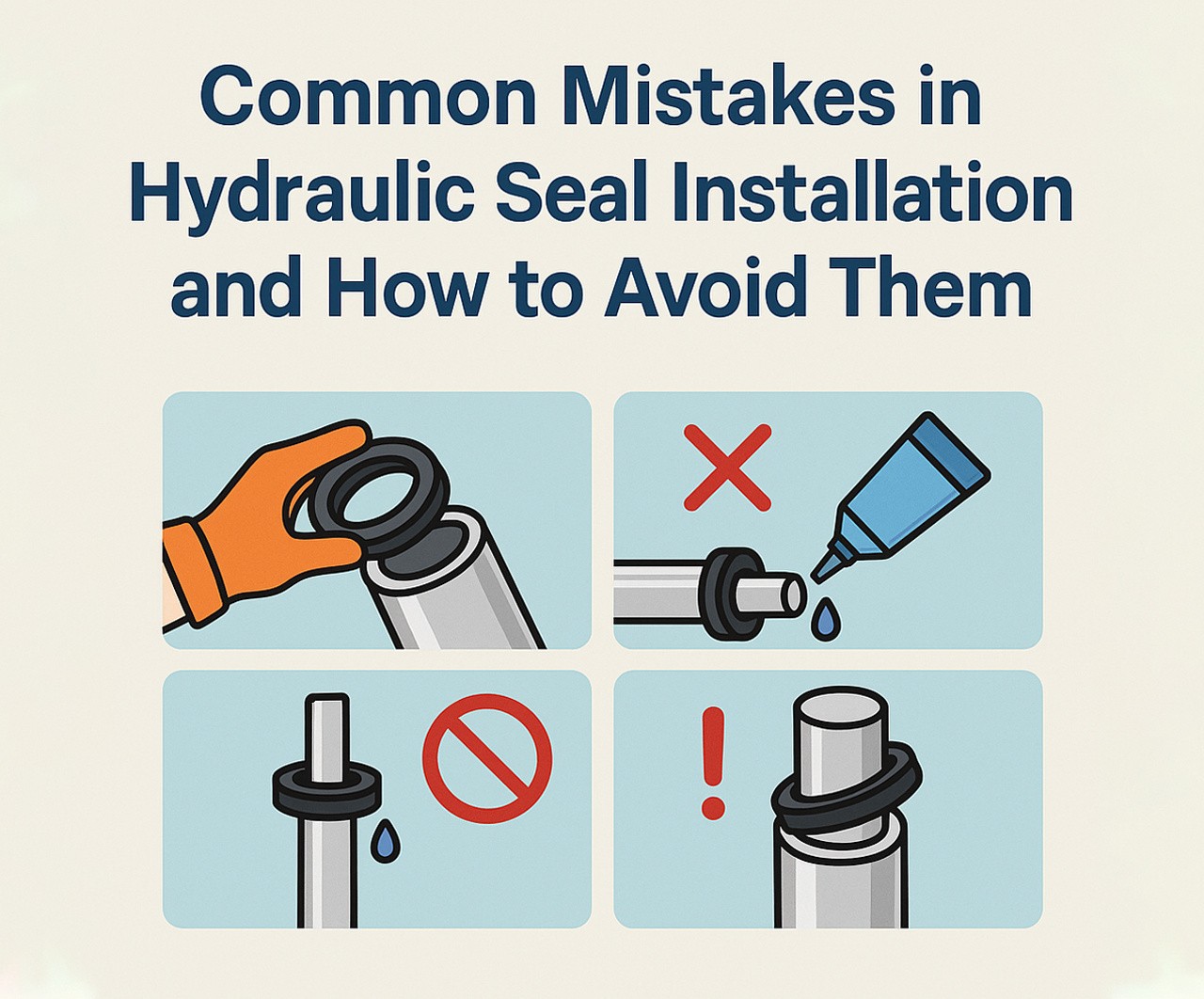

Installing oil seal hydraulic components, piston seals for hydraulic cylinders, or searching for hydraulic seals near me may seem routine, but small errors during installation can cause massive headaches down the road. Leaks, pressure drops, and premature wear are often the result of simple oversights—many of which are entirely preventable. Whether you’re a field technician, maintenance engineer, or OEM manufacturer, understanding the most common seal installation mistakes can save time, money, and frustration.

This guide unpacks the biggest pitfalls in hydraulic seal installation and how to do the job right the first time. Know more..

Why Proper Seal Installation Matters

Hydraulic systems rely on precisely engineered seals to contain fluid, prevent contamination, and maintain system pressure. The function of oil seal hydraulic components or piston seals for hydraulic cylinders is critical to system efficiency and safety. A poorly installed seal can lead to:

- Hydraulic fluid leaks

- Degraded performance

- Environmental hazards

- Costly downtime

For industries relying on uptime—construction, manufacturing, mining, agriculture—the stakes are even higher. If you’re sourcing or looking for hydraulic seals near me, make sure you also focus on how they’re installed.

Mistake #1: Using the Wrong Seal Type

Not all seals are created equal. Mixing up rod seals with piston seals for hydraulic cylinders, or using an oil seal hydraulic designed for rotary shafts in a reciprocating application, leads to poor sealing performance and early failure.

How to Avoid It:

- Know your application requirements: pressure, temperature, movement type (reciprocating, rotary, static).

- Use manufacturer charts to confirm compatibility.

Consult a professional supplier (especially when searching hydraulic seals near me) to verify the correct type.

Mistake #2: Poor Surface Preparation

Seals are only as good as the surfaces they’re installed on. Burrs, dirt, old sealant, or scratches on the sealing surface can damage a new oil seal hydraulic during installation and compromise sealing effectiveness.

How to Avoid It:

- Clean the shaft, bore, and grooves thoroughly before installation.

- Remove old seal remnants completely.

- Polish minor scratches; replace parts with deep grooves or pits.

Mistake #3: Incorrect Installation Direction

Some piston seals for hydraulic cylinders and wiper seals have a directional design. Installing them backward means they won’t function correctly, leading to immediate or delayed failure.

How to Avoid It:

- Check seal markings or documentation for directional indicators.

- Reference exploded diagrams from the OEM.

If unsure, ask the supplier while sourcing hydraulic seals near me to clarify orientation.

Mistake #4: Improper Lubrication

Installing a dry oil seal hydraulic can tear or distort the material, especially during press-fit or stretch-fit methods.

How to Avoid It:

- Always apply compatible lubricant to the seal and mating surfaces.

- Use assembly grease or system fluid—never petroleum jelly unless the seal material allows it.

- Lubricate piston seals for hydraulic cylinders liberally to prevent sticking on startup.

Mistake #5: Forcing the Seal

Overstretching or forcing a seal into a groove with tools can permanently deform it, causing compression set, nicks, or edge damage. This is especially common when users install oil seal hydraulic rings into tight bores or use screwdrivers instead of proper tools.

How to Avoid It:

- Use plastic or brass seal installation tools—not metal ones that can scratch or puncture the seal.

- Warm the seal slightly (if the material allows) to make it more pliable.

- Use clamps, tapered sleeves, or installation cones for even seating.

Mistake #6: Using the Wrong Seal Material

Choosing the wrong material for your environment—temperature, chemicals, or pressure—will degrade a seal quickly, regardless of proper installation.

How to Avoid It:

- For oil seal hydraulic needs, match the material (NBR, FKM, PTFE, etc.) to the fluid type and system temperature.

- For piston seals for hydraulic cylinders, consider wear resistance, extrusion resistance, and compression set properties.

- Trusted suppliers for hydraulic seals near me can guide you to application-specific materials.

Mistake #7: Not Checking for Shaft or Bore Wear

Even with the best oil seal hydraulic products, a worn shaft or cylinder bore will compromise the seal. Over time, surface roughness and misalignment will chew through new seals prematurely.

How to Avoid It:

- Inspect mating surfaces using micrometers and calipers.

- Replace or re-machine shafts and bores if tolerances are exceeded.

- Pay attention to shaft runout, concentricity, and finish.

Mistake #8: Mixing Old and New Seals

Sometimes, only one seal in a set shows visible wear—but mixing old seals with new ones can throw off pressure balance and wear timing.

How to Avoid It:

- Replace all related seals in a system or assembly at once.

- For piston seals for hydraulic cylinders, always install matching rod seals, wear rings, and wipers if they’re part of a seal kit.

Mistake #9: Ignoring Installation Temperature

Seals installed in extreme temperatures—either too hot or too cold—may stretch, shrink, or crack.

How to Avoid It:

- Install at room temperature when possible.

- Store seals properly to avoid temperature-related deformation.

- If you’re sourcing hydraulic seals near me, ask about storage recommendations and installation temperatures.

Mistake #10: Skipping Final Inspection

Failing to inspect installed seals often leads to problems discovered only during operation—by then, it’s too late.

How to Avoid It:

- Visually inspect each seal after installation for pinching, uneven compression, or misalignment.

- Perform a pressure test before putting the system back into full operation.

Tools That Make Seal Installation Easier

Professional installation tools make a huge difference in avoiding damage to the oil seal hydraulic or piston seals for hydraulic cylinders. Some helpful tools include:

- Seal picks and hooks (plastic or brass)

- Tapered seal installation sleeves

- Seal expanders for large-diameter seals

- Seal compression clamps for U-cups and V-rings

If you’re working without access to these, many suppliers listed when searching hydraulic seals near me offer rental kits or affordable tool packages.

What to Look for in a Seal Supplier

Finding high-quality hydraulic seals near me goes beyond convenience. Look for:

- Inventory variety: Can they supply different sizes, materials, and seal types?

- Expertise: Can they help identify and match OEM specs?

- Support: Do they provide installation guides or engineering support?

- Speed: Can they deliver or ship quickly to reduce downtime?

Good suppliers not only provide the seal but ensure it’s the right seal, with the right tools and support to do the job right.

The Cost of Getting It Wrong

Improper installation of oil seal hydraulic components or piston seals for hydraulic cylinders often leads to:

- Repeated downtime

- Hydraulic fluid loss

- Environmental fines

- Damage to other system components

Investing an extra 10–15 minutes to install correctly saves hours (and thousands of dollars) later.

Final Thoughts

Avoiding common installation mistakes with oil seal hydraulic and piston seals for hydraulic cylinders isn’t difficult—but it does require the right knowledge, tools, and attention to detail. Whether you’re replacing worn components or building a new hydraulic system, proper seal installation is critical to long-term reliability.

From identifying the right seal material to using the correct technique, every step matters. And if you’re ever unsure, searching for hydraulic seals near me and connecting with a trusted local supplier can provide both the product and guidance you need.