In demanding mechanical environments where speed, pressure, and temperature converge, sealing reliability becomes non-negotiable. That’s why the PTFE seal, PTFE O ring, and PTFE shaft seal have become the go-to choices in industries pushing the limits of performance. From high-speed motors to aerospace components, PTFE-based seals are redefining expectations for durability, chemical resistance, and efficiency. As design engineers search for smarter solutions, PTFE lip oil seals stand out as the answer to many high-speed sealing challenges. Know more..

What Makes PTFE Different?

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer with unique physical and chemical properties:

- Extremely low coefficient of friction

- Exceptional thermal resistance (operates reliably between -200°C and +260°C)

- Chemically inert to most industrial solvents and corrosives

- Self-lubricating and non-stick surface

- High wear resistance under sliding conditions

These qualities make a PTFE seal incredibly durable under conditions that would degrade or destroy traditional elastomer seals.

Understanding PTFE Lip Seals

A PTFE lip oil seal combines the high-performance properties of PTFE with a dynamic sealing lip designed to maintain tight contact with a rotating shaft. Unlike traditional rubber or nitrile seals, which depend heavily on lubrication and temperature control, a PTFE shaft seal maintains its structural integrity even at very high speeds and low lubrication scenarios.

Key Design Features:

- PTFE lip molded or machined for precision fit

- Stainless or coated steel casing for structural stability

- Can be spring-energized to maintain sealing force

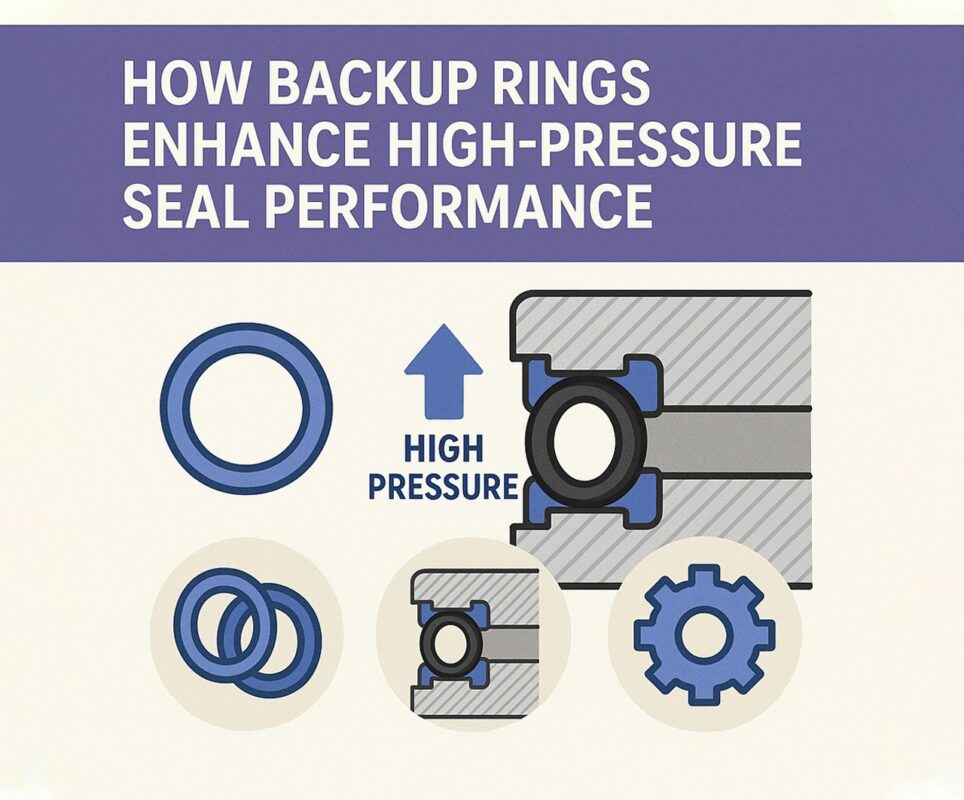

- Often used with backup PTFE O ring for static sealing

Why PTFE Seals Excel in High-Speed Environments

High-speed applications introduce unique stresses:

- Increased friction and heat at the sealing surface

- Higher centrifugal forces that can deform standard seals

- Rapid wear and fatigue of elastomeric materials

The PTFE seal, by contrast, offers:

- Low friction to reduce energy loss and heat buildup

- Excellent wear resistance at high RPMs

- Non-aging material that resists cracking or swelling

- Chemical compatibility with synthetic and aggressive lubricants

This makes it ideal for:

- Turbochargers

- High-speed spindles

- Jet engine components

- High-RPM gearboxes and pumps

Comparing PTFE to Traditional Seal Materials

| Property | Nitrile Rubber | Viton | PTFE |

| Max Temperature | 120°C | 200°C | 260°C |

| Chemical Resistance | Moderate | Good | Excellent |

| Friction Coefficient | Moderate | Low | Very Low |

| Wear Rate | Moderate | Moderate | Low |

| Cost | Low | High | High (but durable) |

Clearly, a PTFE shaft seal provides the best combination of long-term performance and reliability when speed and environmental stress are involved.

Creative Applications Across Industries

The versatility of the PTFE seal, PTFE O ring, and PTFE shaft seal extends across numerous sectors. Here are some novel and high-performance applications:

1. Electric Vehicle Drivetrains

High-speed electric motors benefit from PTFE shaft seals that reduce drag, resist heat, and extend range.

2. Aerospace Hydraulic Systems

In high-pressure and high-altitude conditions, PTFE O rings and seals ensure leak-free, temperature-resistant performance.

3. Pharmaceutical Manufacturing

Where cleanliness and chemical resistance are key, PTFE seal systems eliminate contamination risk and reduce cleaning downtime.

4. Food & Beverage Processing

FDA-grade PTFE O rings and shaft seals meet hygiene standards while surviving exposure to acids, CIP chemicals, and steam.

5. CNC and Machine Tooling

High-speed spindles rely on PTFE shaft seals for low-friction, non-lubricated sealing over thousands of cycles.

The Hybrid Approach: Combining PTFE and Elastomers

Some modern seal designs incorporate both PTFE and elastomeric materials to balance flexibility and resilience. A PTFE shaft seal may feature:

- A PTFE lip for sliding contact

- An elastomer outer casing for vibration damping

- An integrated PTFE O ring for static face sealing

This hybrid design reduces cost while maximizing performance in less demanding applications.

Real-World Case Study: High-Speed Packaging Machinery

A multinational packaging equipment manufacturer replaced conventional rubber seals with custom PTFE shaft seals in high-speed filling machines. The results:

- 3x longer seal life

- 50% reduction in downtime due to leaks

- Elimination of seal drag, improving energy efficiency by 8%

Operators praised the switch for its reliability and maintenance ease, especially in machines operating 24/7.

PTFE O Rings: Small Component, Big Impact

Though small, the PTFE O ring plays a critical role in high-pressure and chemically aggressive environments. Unlike rubber O-rings that swell, degrade, or crack, a PTFE O ring maintains its shape and integrity even under thermal cycling and exposure to solvents or acids.

Typical use cases:

- Semiconductor wafer processing

- High-purity chemical delivery systems

- Vacuum sealing in laboratory and space equipment

- Cryogenic sealing in liquified gas systems

Customization and Advanced Design Options

PTFE seals and PTFE O rings can be customized for specific high-speed needs:

- Filled PTFE: With additives like glass, carbon, or bronze to enhance wear resistance

- Spring-energized: PTFE lip supported by stainless steel spring for dynamic loads

- Textured sealing lips: Micro-geometry to reduce wear or channel lubrication

These innovations expand PTFE’s usability and performance in almost any application.

Installation Tips for PTFE Seals

Because of its low elasticity, installing a PTFE shaft seal requires care:

- Preheat if necessary: Some seals need gentle heating to ease expansion.

- Use installation tools: Avoid bending or folding the lip.

- Avoid overcompression: PTFE doesn’t rebound like rubber; excessive force can cause leaks.

- Pre-lubricate or dry install: Depending on the application, follow manufacturer instructions precisely.

When installed correctly, a PTFE seal can perform far beyond traditional expectations.

The Environmental and Economic Edge

Besides performance, PTFE shaft seals offer sustainability benefits:

- Longer lifespan: Fewer replacements reduce waste and downtime

- Lower friction: Improves energy efficiency

- Minimal maintenance: Cuts resource use and labor hours

Even with a higher upfront cost, PTFE solutions often pay for themselves over time in industrial and automotive systems.

Debunking Common Myths

- PTFE seals are too expensive

- They cost more initially but last longer and reduce system wear.

- PTFE is too brittle

- Modern filled PTFE variants are incredibly durable and flexible within range.

- Not suitable for dynamic sealing

- On the contrary, the PTFE shaft seal is engineered for high-speed rotation and reciprocation.

- Only for extreme applications

- PTFE is increasingly common in consumer goods, EVs, and household appliances where performance counts.

Looking Ahead: Smart PTFE Seals

The future of the PTFE seal and PTFE O ring includes integration with digital systems:

- Embedded micro-sensors: Monitor temperature and wear in real-time

- AI-driven seal selection: Algorithms match PTFE materials to specific load profiles

- Recyclable PTFE composites: Sustainable sealing without compromising performance

Final Thoughts: The Unmatched Value of PTFE in High-Speed Sealing

The PTFE seal, PTFE O ring, and PTFE shaft seal represent more than just a technological leap—they reflect a new philosophy in engineering: one that values longevity, reliability, and performance under pressure. Whether it’s extending the life of an electric motor or ensuring a pharmaceutical line runs contamination-free, PTFE delivers.

As industries move faster, hotter, and cleaner, traditional materials just can’t keep up. That’s why engineers are turning to PTFE—not just as an alternative, but as the standard for high-speed, high-performance sealing.

So, the next time your design calls for speed, pressure, and precision, remember the power of the PTFE seal. It could be the smallest component in your system—but it might just make the biggest difference.