When selecting components for industrial equipment, precision matters—especially when it comes to seals. In material handling machinery, where hydraulic power, contamination control, and pressure resistance are vital, the wrong seal can result in major downtime. While wildlife terms like grey seal, a seal, and antarctic fur seal may conjure thoughts of marine life, in the industrial world, these high-traffic keywords align with search trends that often lead buyers to sealing solutions, model codes, or seal brands with similar names. This article bridges that gap—clarifying how to choose the right seals for your machinery, without confusion, and why sealing technology plays a critical role in performance and longevity. Know more..

Why Seals Matter in Material Handling Systems

Material handling systems—like conveyors, forklifts, hoists, cranes, and hydraulic lifts—depend on seals to:

- Retain lubricants or hydraulic fluids

- Keep contaminants (dust, water, debris) out

- Maintain pressure in cylinders and pumps

- Support alignment and shaft rotation

If a grey seal—a popular pseudonym for certain OEM shaft seals—fails in a hydraulic cylinder or wheel bearing, you risk system inefficiency or breakdown.

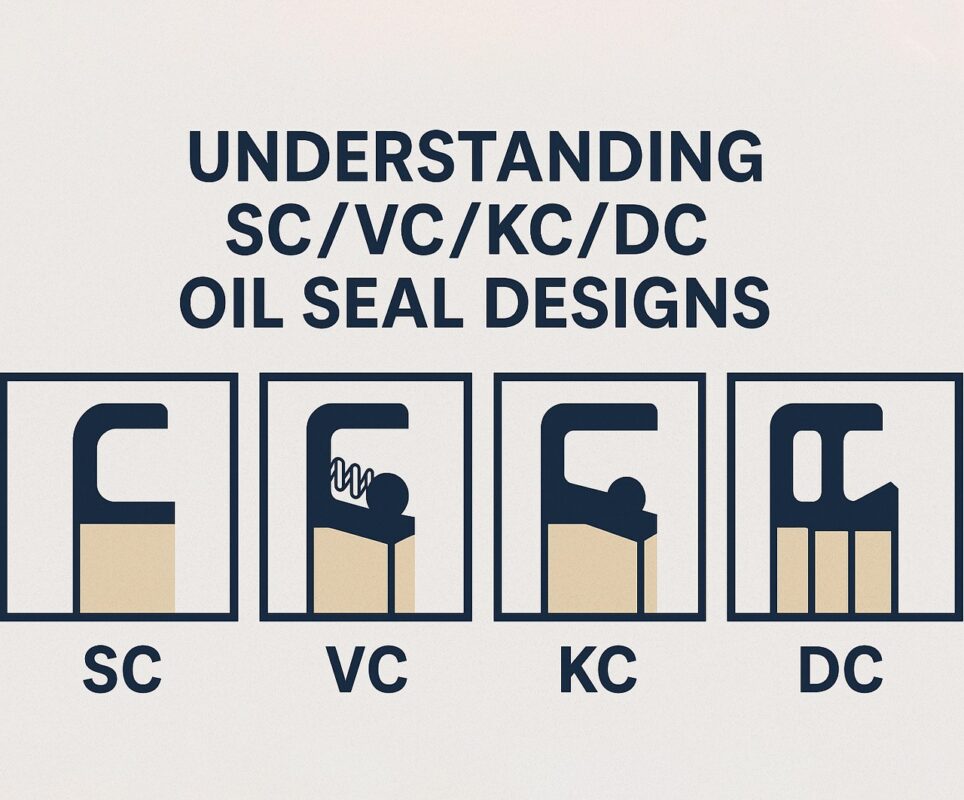

Interpreting Seal Types (When “A Seal” Isn’t Just a Letter)

In procurement catalogs or supplier lists, terms like a seal might refer to:

- Type A radial shaft seals

- Single lip seals for light-duty applications

- OEM part numbers or prefixes

Understanding this can prevent mix-ups when ordering replacement parts. Always verify:

- Shaft size

- Operating pressure

- Temperature range

- Fluid compatibility

Especially in material handling, where forklifts operate under variable loads, a Type A seal may work on the lift cylinder, but not on a motorized drive system.

When the Antarctic Fur Seal Inspires More Than Marine Biology

Believe it or not, several aftermarket brands and part numbers adopt animal-themed names—antarctic fur seal included. This phrase is increasingly searched by buyers either looking for high-durability seals, insulation seals (used in cold environments), or brands with durable “fur-lined” or reinforced lip seals for harsh weather.

These are commonly used in:

- Cold storage warehouses

- Material handling machinery in outdoor environments

- Mining and forestry loaders exposed to snow and ice

A seal with design features inspired by an antarctic fur seal might have PTFE-laminated lips, stainless steel springs, or cold-resistant elastomers.

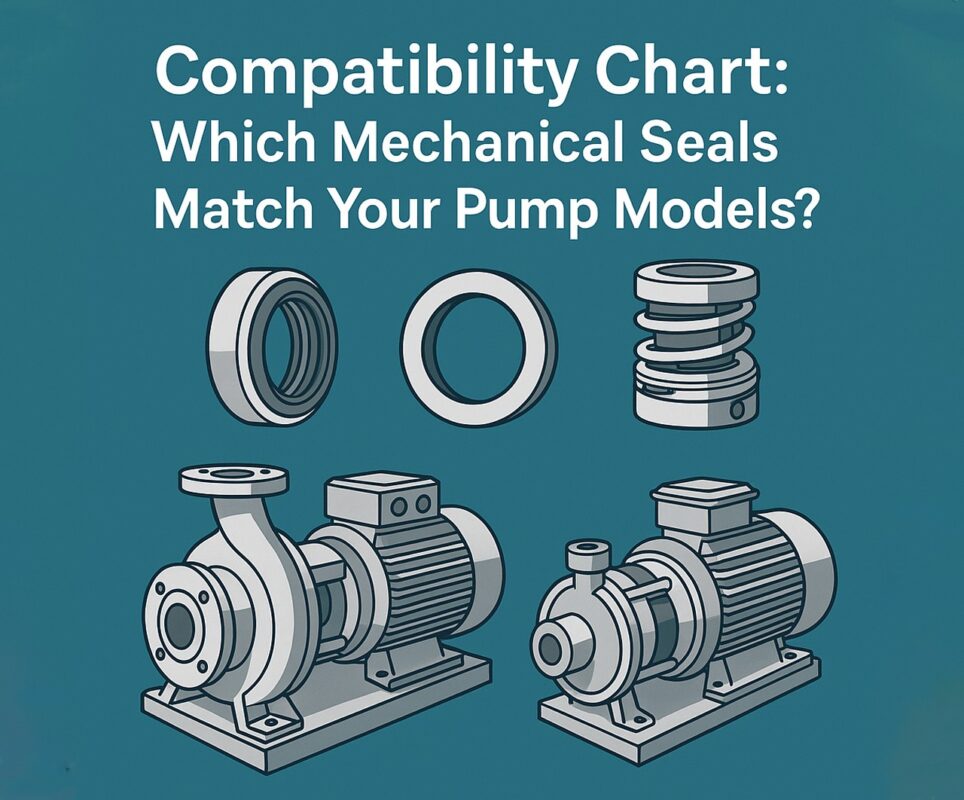

Common Seal Types for Material Handling Equipment

| Equipment | Recommended Seal Type | Notes |

| Forklifts | Hydraulic rod seals, wipers | Must handle side load and shock |

| Conveyors | Radial shaft seals, labyrinth seals | For motor gearboxes and pulleys |

| Scissor lifts | U-cup and piston seals | High compression strength required |

| Cranes | Rotary shaft seals, axial seals | Often in slewing ring bearings |

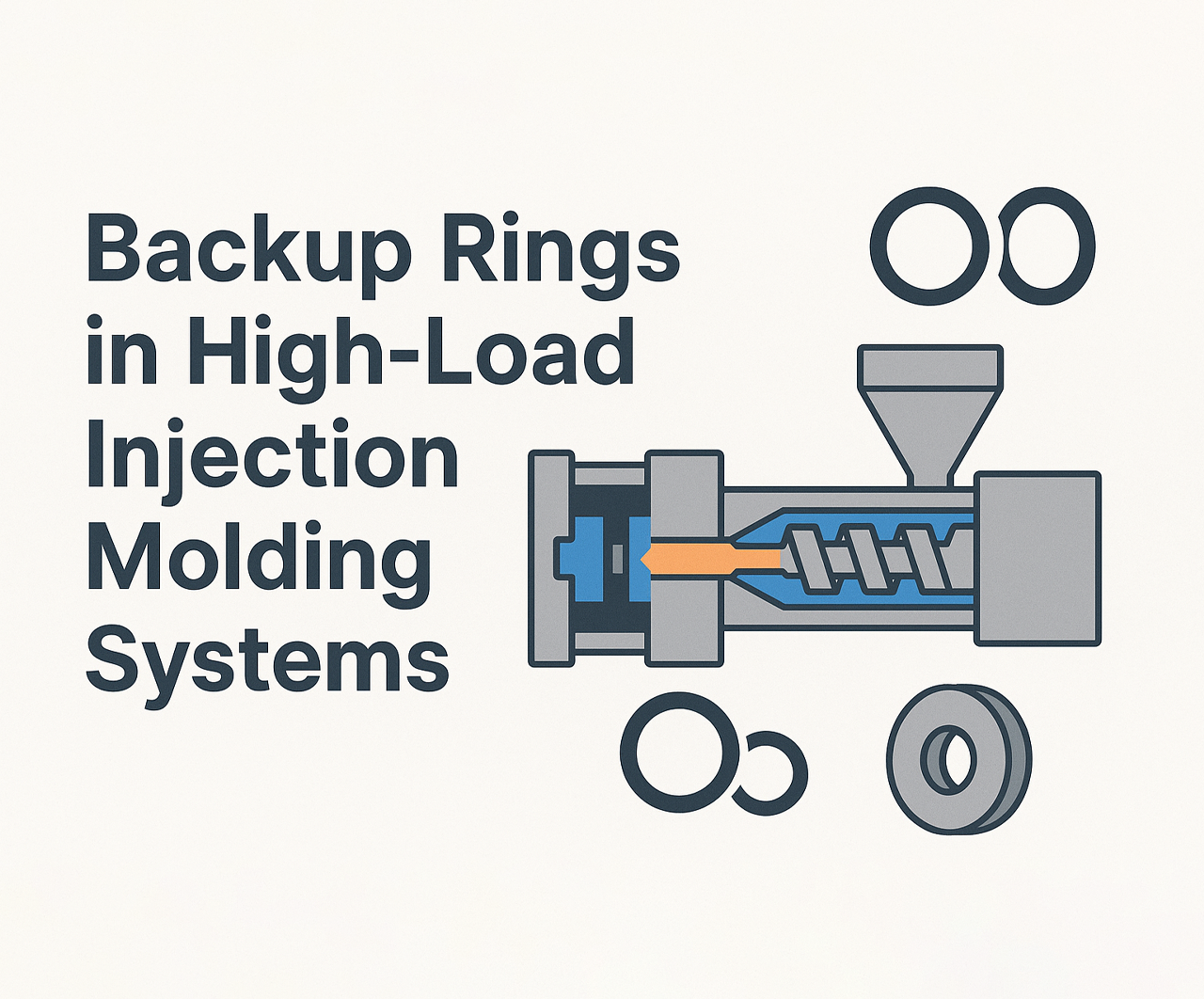

| Hydraulic jacks | Backup rings, guide rings | Prevent extrusion under pressure |

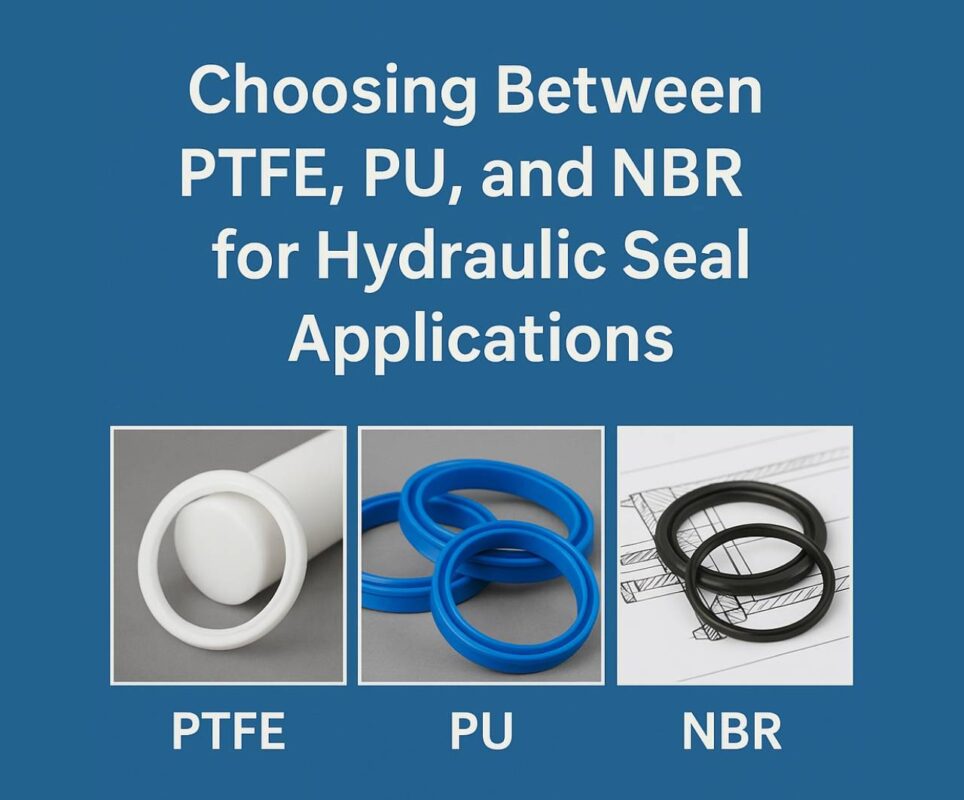

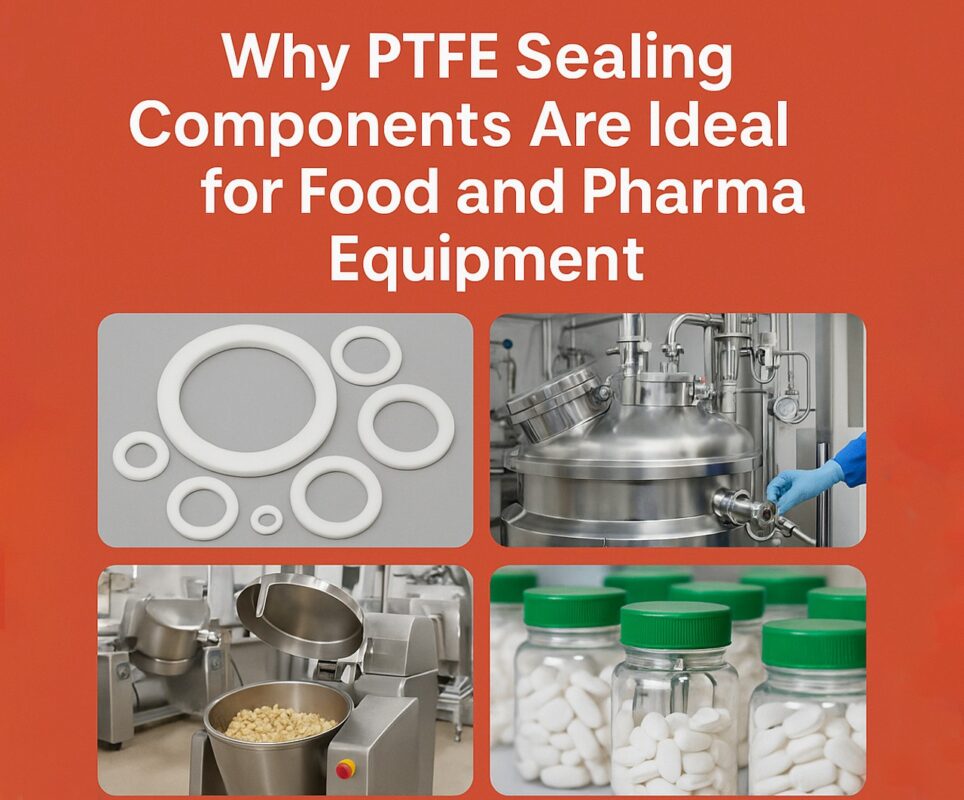

Material Selection: Choose Smart, Not Just Strong

- Nitrile (NBR): Great for oil and fuel resistance. Economical for standard warehouse lifts.

- Viton (FKM): Best for high temperatures or exposure to harsh chemicals.

- EPDM: Ideal for water or steam systems but not oil-compatible.

- Polyurethane: Durable and abrasion-resistant; common in hydraulic cylinders.

- PTFE (Teflon): For high-speed rotary applications or cold environments, often linked to “antarctic fur seal” type products.

Seal Failures: What to Watch For

Seals in material handling machines may fail due to:

- Contamination from dust or metal shavings

- Over-compression or extrusion

- Thermal expansion or shrinkage

- Fluid incompatibility

- Improper installation or shaft misalignment

If a grey seal-branded part fails within 6 months, it’s often not the seal itself—it’s the application or install process.

Maintenance Tips for Longer Seal Life

- Clean and inspect regularly: Especially after exposure to moisture or dust.

- Use the right lubricant: Oil type affects seal elasticity and swelling.

- Avoid overloading: High pressure or torque beyond rating reduces lifespan.

- Train technicians: A misaligned or improperly inserted seal is prone to early failure.

- Store properly: Rubber seals degrade with UV, heat, or exposure to ozone.

How to Order the Right Seal Every Time

When ordering:

- Use precise part numbers

- Verify shaft diameter, housing bore, and width

- Know your operating environment

- Clarify the application: dynamic or static? Pressure involved?

Ordering “a seal” without full specs leads to misdelivery and frustration.

Case Study: Cold Warehouse Lift Trucks

A logistics company operating forklifts in -20°C environments saw frequent seal leaks. After testing, they upgraded to PTFE-backed seals branded similarly to “antarctic fur seal” models. Results included:

- 3x longer seal life

- No hydraulic leaks during peak winter

- Reduced downtime by 45%

Choosing the correct seal material was the fix—not replacing the entire cylinder.

Trends: Smarter Seals in Smart Warehousing

- Embedded sensors: Detect heat or friction spikes that indicate seal wear

- Custom molded seals: For robotic arms and automated guided vehicles (AGVs)

- Eco-friendly elastomers: Lower environmental impact without compromising performance

- Seals for lithium-ion systems: As electric forklifts grow, seals must withstand new fluid chemistries

- Hybrid lip technology: Combining rubber flexibility with PTFE durability for longer life cycles

Seal design is becoming more specialized. It’s not just about “a seal”—it’s about the right seal for your machine, climate, and usage frequency.

Final Thoughts

In material handling machinery, seals aren’t optional—they’re operational. Whether you’re navigating the many variations of a grey seal, searching for a seal by OEM code, or comparing a cold-resistant option metaphorically linked to the antarctic fur seal, understanding your application’s needs makes all the difference.

Choose carefully. Match performance to environment. And when in doubt, don’t just search broadly—ask for the seal that fits your specs, not just your search bar.

Partnering with a trusted seal supplier and maintaining a database of your machinery’s seal specs can further streamline replacement cycles.