In demanding industrial settings—whether oil rigs, chemical plants, or high-speed manufacturing—seal failure isn’t an inconvenience; it’s a catastrophe. That’s why engineers are scrutinizing every component, including seals, more than ever. Among the most searched and trusted options today are Parker Clipper oil seals, Parker seals, and Parker metal seals. But with growing competition, especially from emerging brands like TECNOLAN, how do you know which seals truly perform under pressure?

This article puts Parker and TECNOLAN head-to-head, comparing seal design, material resilience, and performance in hostile conditions. If you’re in procurement, MRO, or system design, this guide will help you make an informed, performance-first decision. Know more..

Why Seal Selection Matters in Harsh Environments

Seals prevent contamination, retain pressure, and protect equipment. In aggressive conditions involving high temperature, pressure fluctuations, or corrosive chemicals, even a minor leak can cause major failures.

The right seal, like Parker oil seals, must withstand:

- Extreme temperatures (sub-zero to 300°C+)

- Vibration and shaft misalignment

- Abrasive particles or media

- High RPM and pressure cycles

That’s where the engineering behind Parker Clipper oil seals and Parker metal seals has earned decades of trust. But TECNOLAN, a newer European brand, is gaining attention for its customization and rapid delivery. So, how do they compare?

Overview of Parker Sealing Solutions

1. Parker Clipper Oil Seals

Clipper seals are known for their easy-to-install, press-fit metal casing and flexible sealing lip. They’re ideal for rotary shaft applications where minimal downtime is critical.

Key features:

- Split design available

- High-performance elastomers

- Withstands shaft speeds up to 4000 fpm

2. Parker Oil Seals (Standard)

Available in a wide range of materials including nitrile, FKM, and HNBR, Parker oil seals are used in automotive, industrial, and heavy-duty applications.

Advantages:

- Wide temperature and pressure range

- Broad fluid compatibility

- Available in inch and metric sizes

3. Parker Metal Seals

For ultra-high pressure and vacuum environments, Parker metal seals use C-rings, E-rings, and O-rings made from Inconel, stainless steel, and other exotic alloys.

Highlights:

- Zero permeability

- Used in aerospace, semiconductor, and nuclear systems

- Excellent spring-back under thermal cycling

Overview of TECNOLAN Sealing Products

TECNOLAN is a niche manufacturer specializing in custom sealing solutions for OEMs across Europe. They offer:

- Thermoplastic elastomer (TPE) seals

- Custom-molded profiles

- Rapid prototyping and small-batch runs

While they don’t match the breadth of Parker oil seals, TECNOLAN’s strength lies in flexibility and fast turnaround for niche needs.

Use cases:

- Agricultural equipment

- Hydraulic cylinders

- Specialty valves

Head-to-Head: Parker vs. TECNOLAN in Key Categories

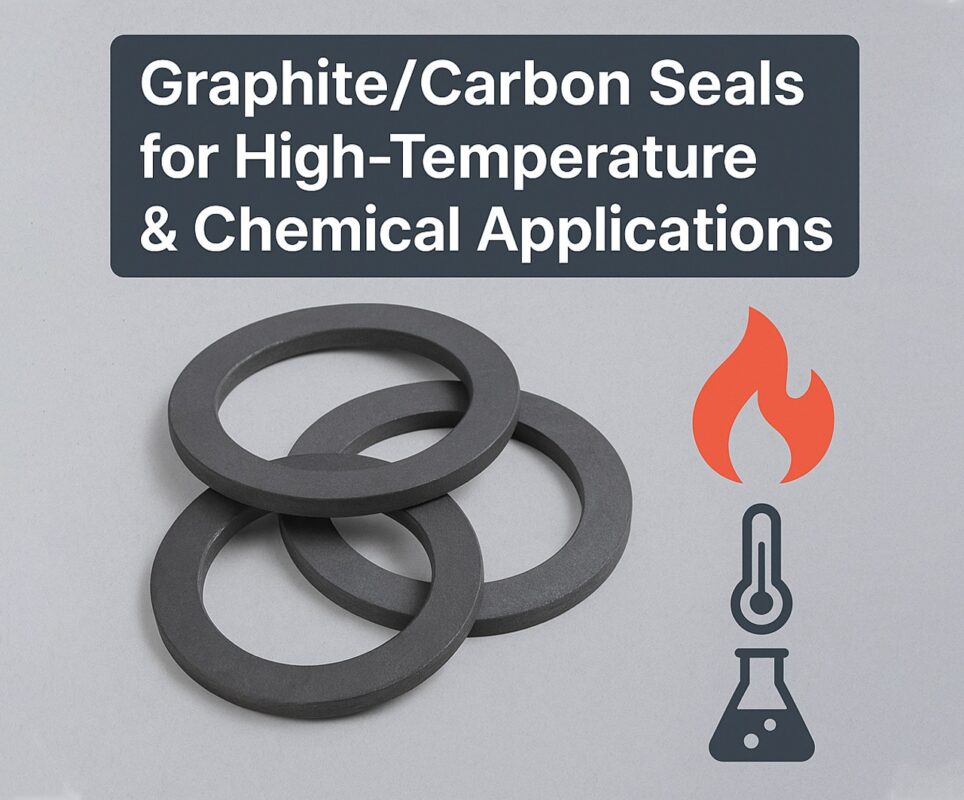

1. Material Engineering

- Parker Clipper oil seals are crafted from proprietary blends like Parker’s PTFE-Bronze or Fluorocarbon elastomers. Excellent for high-speed or chemically aggressive media.

- TECNOLAN uses standard TPEs and nitrile blends. Suitable for general-duty, low-heat applications.

Winner: Parker (especially in chemical resistance and wear)

2. Temperature Resistance

- Parker oil seals handle -40°C to 260°C depending on compound.

- TECNOLAN’s seals are generally limited to -20°C to 120°C.

Winner: Parker (wider thermal window)

3. Customizability

- TECNOLAN shines with rapid prototyping and short-run flexibility.

- Parker also offers custom solutions, but generally with higher MOQs.

Winner: TECNOLAN (for bespoke, small-volume needs)

4. Durability Under Load

- Parker metal seals can operate under 20,000 psi and in vacuum environments.

- TECNOLAN products are not rated for ultra-high pressure systems.

Winner: Parker (especially for aerospace or nuclear use)

5. Global Availability

- Parker seals are available globally through a vast distributor network.

- TECNOLAN is Europe-focused with limited global reach.

Winner: Parker (better logistics and service support)

Application-Specific Comparisons

| Application | Best Option | Why |

| High-Speed Rotary Shafts | Parker Clipper oil seals | Handles shaft misalignment and speeds >4000 fpm |

| Automotive Gearboxes | Parker oil seals | OEM trusted with wide fluid compatibility |

| Aerospace or Cryogenics | Parker metal seals | Withstands pressure, temperature, and vacuum |

| Custom Tooling Machines | TECNOLAN | Fast prototyping and low MOQ options |

| Standard Hydraulics | Tie | Both offer solid performance |

Cost Comparison

- Parker seals are more expensive upfront but lower TCO due to extended service life.

- TECNOLAN provides cost-effective alternatives for non-critical applications or short-term use.

For critical environments, the higher price of Parker metal seals and Parker oil seals pays off in uptime and reliability.

End-User Reviews and Case Studies

Parker

A global packaging plant replaced standard rubber rotary seals with Parker Clipper oil seals and increased seal life from 6 months to 2 years, cutting downtime by 35%.

TECNOLAN

A small CNC machine builder in Spain used TECNOLAN’s TPE profiles to create custom groove seals in less than 3 weeks. While not rated for high-pressure, they delivered well in moderate conditions.

Sustainability and Compliance

Both brands are moving toward greener production:

- Parker offers RoHS and REACH-compliant materials

- TECNOLAN uses recyclable TPEs and minimizes waste in small-run molding

Still, Parker oil seals benefit from longer life spans, reducing frequency of replacement and overall waste.

Which Should You Choose?

Choose Parker If You:

- Need global availability

- Operate in chemically aggressive or high-pressure environments

- equire compliance with aerospace, food, or energy regulations

Use Parker Clipper oil seals for rotary shafts, Parker oil seals for industrial pumps, and Parker metal seals for vacuum systems and extreme pressure applications.

Choose TECNOLAN If You:

- Need fast, low-volume customization

- Operate in moderate conditions

- Want a cost-efficient option for equipment with lower duty cycles

Final Thoughts

In harsh environments, sealing reliability is everything. For critical systems where failure is not an option, Parker Clipper oil seals, Parker oil seals, and Parker metal seals consistently deliver superior performance, durability, and global support.

TECNOLAN offers creative, agile alternatives for specialized machinery or prototyping—but cannot match Parker’s track record in extreme conditions.

Choose wisely. When equipment uptime, safety, and longevity are on the line, the seal you select isn’t just a part—it’s a promise.