In the world of high-purity processing, where hygiene, chemical compatibility, and performance are critical, PTFE bellow seal, PTFE mechanical seal, and PTFE oil seal components stand out as industry game changers. Their unmatched inertness and cleanability make them the go-to choice for food processing and Pharma Equipment manufacturing. From withstanding aggressive cleaning agents to maintaining zero contamination zones, PTFE-based seals are engineered to meet the uncompromising standards of these sensitive environments. Know more..

What Makes PTFE So Unique?

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer known for its non-stick properties, chemical resistance, and thermal stability. Discovered by accident in the 1930s, PTFE has since evolved into one of the most trusted materials in high-performance sealing.

Key Properties of PTFE:

- Chemically inert

- Non-toxic and FDA/USP compliant

- Excellent thermal resistance (-200°C to +260°C)

- Low coefficient of friction

- Non-absorbent and easy to cleanThese properties make PTFE ideal for seals used in food and pharma environments, where cleanliness, reliability, and durability are non-negotiable.

PTFE Bellow Seal: The Flexible Workhorse

The PTFE bellow seal is a versatile, flexible sealing component designed for axial movement while maintaining a high-integrity barrier. Often used in diaphragm pumps, dosing systems, and agitators, this seal type excels where vibration, thermal expansion, or movement is present.

Advantages of PTFE Bellow Seals:

- Absorb movement without losing seal integrity

- Resist aggressive CIP (Clean-In-Place) and SIP (Steam-In-Place) agents

- Eliminate dead zones that trap contaminants

In pharmaceutical reactors and fermentation tanks, a PTFE bellow seal can handle sterilization cycles while preventing cross-contamination—making it essential for aseptic design.

PTFE Mechanical Seal: Built for Tough Rotational Duty

A PTFE mechanical seal is used in rotating equipment like mixers, pumps, and homogenizers. It uses polished PTFE faces and sometimes combines with carbon or ceramic materials to create a dynamic seal that withstands both pressure and motion.

Why PTFE Mechanical Seals Work in Food and Pharma:

- Non-leaching and non-reactive

- Operates under vacuum or pressure

- Compatible with acidic, alkaline, and solvent-based cleaners

- Prevents microbial growth due to non-porous surface

For example, in a dairy bottling facility, a PTFE mechanical seal ensures that milk or yogurt is processed with no risk of contamination from lubricants or degraded elastomers.

PTFE Oil Seal: Clean Containment in Motion

The PTFE oil seal is an upgrade over traditional elastomeric oil seals, especially in hygienic applications where elastomers can degrade or absorb chemicals. These seals are perfect for slow and high-speed shafts in mixers, centrifuges, and filling equipment.

Benefits in Food and Pharma Settings:

- Non-toxic and safe for food contact

- Dry-running capabilities reduce need for lubrication

- Withstands temperature swings and washdowns

- FDA and USP Class VI compliant materials

PTFE’s non-stick nature ensures that grease, powder, or residue doesn’t build up, which is a major plus in powder-handling systems in pharma production.

How PTFE Seals Meet Regulatory Demands

Food and pharmaceutical manufacturing is governed by strict standards:

- FDA CFR 21: For direct food contact materials

- USP Class VI: For biocompatibility in drug production

- EHEDG: Hygienic design in food equipment

Every PTFE bellow seal, PTFE mechanical seal, and PTFE oil seal can be produced using compliant materials, making them safe choices from a regulatory standpoint.

Application Zones in Food and Pharma Equipment

- Mixers and Blenders

- Use PTFE oil seals to prevent ingredient leakage

- Resistant to sugar, fat, and solvent-based flavoring agents

- Filling and Packaging Lines

- PTFE mechanical seals reduce maintenance in high-speed fillers

- Easily withstand washdown and sanitizer exposure

- Reactor Vessels and Tanks

- PTFE bellow seals handle agitation and temperature fluctuations

- Sterile barrier for vaccine or injectable production

- Centrifuges and Separators

- PTFE components reduce product contact area and ease cleaning

- Pumps

- Sanitary pumps benefit from PTFE’s resistance to both cleaning fluids and processed products

Real-World Case Study: Pharmaceutical Blister Packaging

A global pharmaceutical manufacturer faced downtime and contamination risks from failing elastomer seals in its blister packaging machines. After switching to a custom-designed PTFE mechanical seal and PTFE oil seal combo:

Results:

- Increased uptime by 30%

- Eliminated need for frequent lubrication

- Passed FDA and EU regulatory audits with zero seal-related concerns

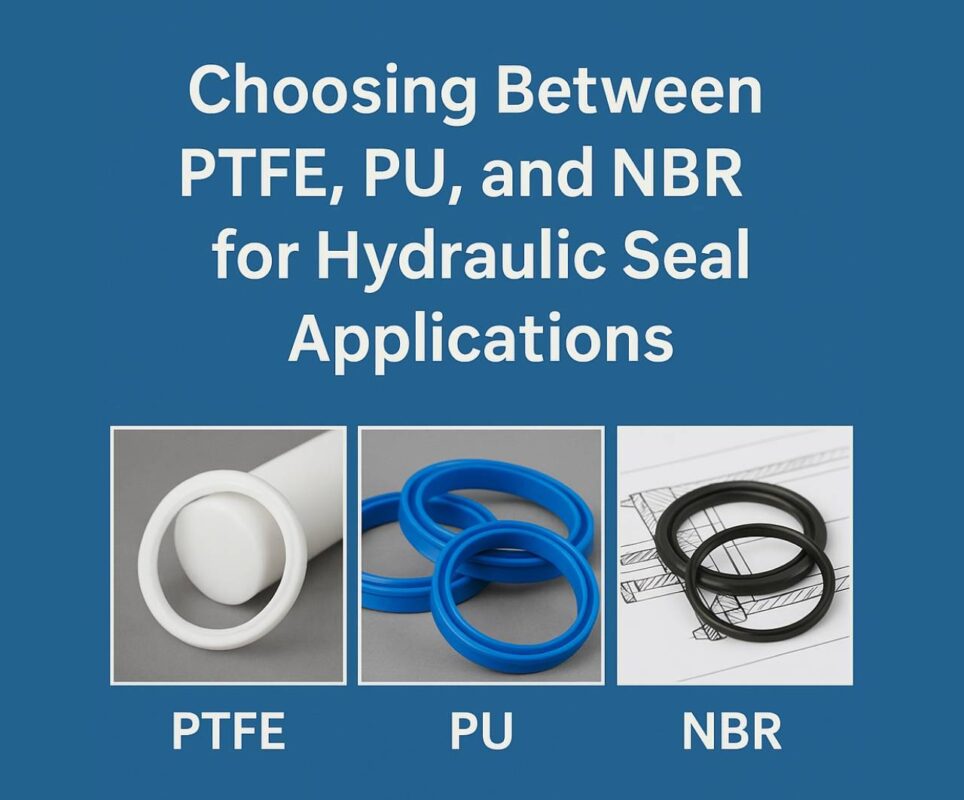

PTFE vs. Other Seal Materials

| Property | PTFE | EPDM | FKM (Viton) | Silicone |

| Chemical Resistance | Excellent | Moderate | Good | Fair |

| Temperature Range | -200°C to +260°C | -40°C to +150°C | -20°C to +200°C | -60°C to +200°C |

| Absorption | None | Slight | Moderate | High |

| Surface Porosity | Very Low | Moderate | Low | High |

| Regulatory Approval | FDA, USP | FDA | FDA | FDA |

PTFE clearly leads in chemical and thermal resistance while being the easiest to sanitize and least likely to harbor microbes.

Considerations for PTFE Seal Design

- Expansion under heat: PTFE expands more than metal, so groove tolerances must account for this.

- Creep and cold flow: Design to limit long-term deformation under load

- Lubrication: While PTFE can run dry, adding compatible lubricants can increase lifespan

- Support rings: Many PTFE seals include metal or elastomer inserts for structural stability

Sustainability and Lifecycle Impact

PTFE is durable, which means fewer replacements and less waste over time. In systems where PTFE mechanical seals or PTFE oil seals last five to ten times longer than rubber alternatives, the environmental and economic savings add up fast.

Also, PTFE is recyclable through specialized processes and can be repurposed into non-critical components, giving it a second life.

The Future of PTFE in Food and Pharma

- Smart Seals: Embedded RFID or NFC chips in PTFE seals for real-time validation

- Advanced Coatings: Nanotechnology to further reduce sticking and cleaning time

- Hybrid Designs: PTFE with elastomer cores for better mechanical flexibility

- 3D-Printed PTFE: Custom sealing geometries for microfluidic or specialty pharma equipment

These trends promise to make PTFE bellow seal, PTFE mechanical seal, and PTFE oil seal solutions even more indispensable.

Final Thoughts: Clean, Compliant, and Reliable

When uptime, compliance, and contamination control are mission-critical, PTFE isn’t just a good option—it’s the best one. Whether you’re optimizing a dairy line, upgrading pharmaceutical reactors, or designing sterile mixing systems, PTFE oil seal, PTFE bellow seal, and PTFE mechanical seal components offer unmatched performance.

In the world of food and pharma, there’s no room for sealing failure. PTFE gives manufacturers peace of mind by combining cleanability, chemical resistance, and regulatory trust into a single, powerful material solution. Seal smart. Choose PTFE.