In modern automation environments, protecting pneumatic components is more critical than ever. Equipment longevity, efficiency, and safety all depend on robust wear prevention strategies. When systems begin to fail, it’s often due to degradation in pneumatic wear bands, improper pneumatic cylinder repair, or overlooked pneumatic piston seals. These components play a central role in minimizing friction, reducing energy loss, and keeping machinery running without interruption. This article explores why wear protection matters, the signs of wear-related failure, and how proactive design and maintenance protect your investment. Know more..

Understanding Wear in Pneumatic Systems

Pneumatic systems rely on compressed air to transmit motion through cylinders and actuators. As air pushes against a piston, the internal seals, rods, and cylinder walls are all under mechanical stress. Over time, repeated cycles cause material loss from:

- Friction between moving parts

- Airborne contaminants

- Misalignment

- Improper lubrication

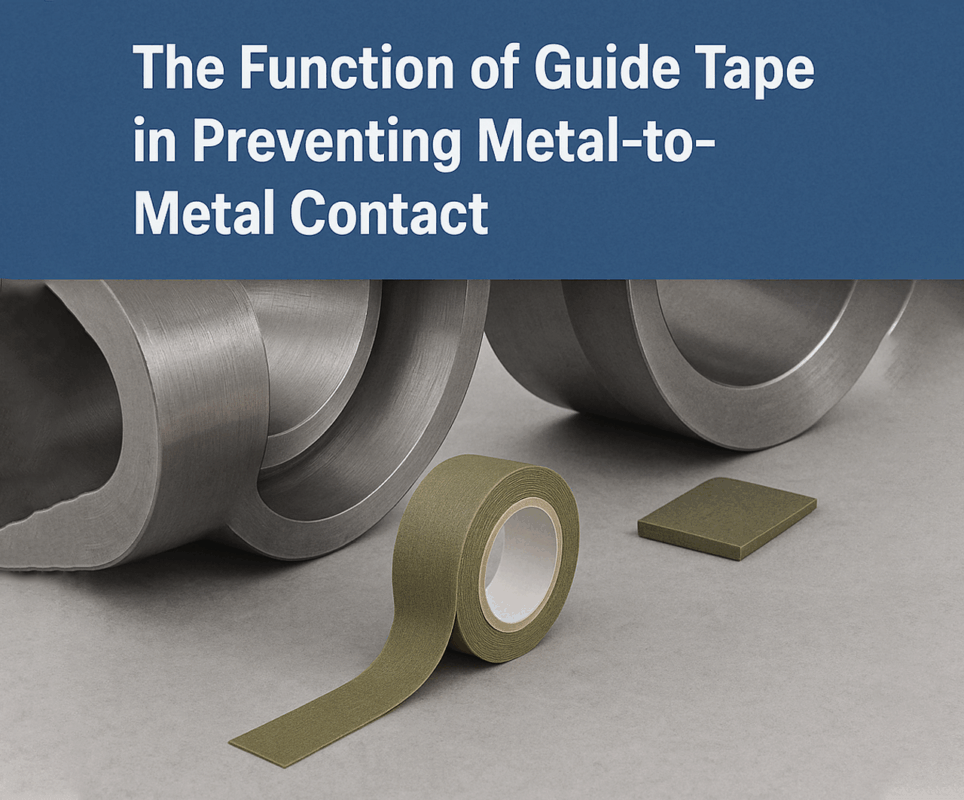

Pneumatic wear bands are often the first line of defense. Installed between the piston and cylinder wall, they prevent metal-to-metal contact and extend system life.

Additionally, these systems are often required to operate in harsh or variable environments. Exposure to extreme temperatures, humidity, or vibration can increase wear rates and challenge component integrity. For industries like food processing, pharmaceuticals, and heavy equipment manufacturing, downtime caused by component failure isn’t just expensive—it can be catastrophic.

Top Wear-Prone Components in Pneumatic Equipment

1. Pneumatic Wear Bands

These guide rings absorb radial loads and stabilize piston movement. Without them, seals wear out faster, and the cylinder bore gets scored. Replacing or upgrading pneumatic wear bands can often solve recurring seal damage and help prevent costly full-cylinder rebuilds.

2. Pneumatic Piston Seals

These maintain pressure within the cylinder and must flex with every stroke. Worn pneumatic piston seals lead to pressure drops, energy inefficiency, and unpredictable motion. These issues reduce machine accuracy and compromise the consistency of automated processes.

3. Rod Seals and Guide Bushings

The exposed rod picks up dust, oil, and debris, which then scratches the seal lip or housing bore. Regular pneumatic cylinder repair includes bushing inspection and seal replacement to prevent long-term damage. Keeping rods clean and protected significantly enhances seal performance and lifespan.

4. Cushion Seals and Bumpers

Often overlooked, these components soften end-of-stroke impact, preventing mechanical shock and internal seal damage. When they wear out, internal components can crash together, amplifying wear throughout the system.

Signs Your Pneumatic System Is Suffering from Wear

- Reduced Speed or Power: Worn components increase air leakage.

- Irregular Motion: Inconsistent strokes or sticking pistons indicate guide or seal wear.

- Excessive Noise: Squealing, hissing, or grinding often signal friction from worn pneumatic wear bands.

- Air Loss or Leaks: Failed pneumatic piston seals cause ongoing pressure drops.

- Scoring Inside Cylinder: A sure sign that the wear bands have failed or are missing.

- Heat Spots or Burn Marks: Overheated areas on rods or cylinders often indicate friction beyond safe limits.

- Contaminated Exhaust Air: Debris expelled from exhaust ports can suggest internal wear or seal erosion.

Causes of Accelerated Wear

- Contaminated Air Supply: Dust or oil particles cause abrasion and seal breakdown.

- Improper Alignment: Causes uneven loading and early failure of pneumatic wear bands.

- High Cycling Rates: Increased friction leads to faster fatigue in pneumatic piston seals.

- Lack of Lubrication: Dry seals generate excessive heat and wear.

- Overpressure: Exceeding design specs stresses all internal components.

- Poor Component Sizing: Using undersized cylinders or actuators for the application increases mechanical stress.

- Inadequate Mounting: Poor installation can transmit vibration or allow rod misalignment, both of which hasten wear.

How to Prevent Premature Wear

1. Upgrade to Advanced Materials

Use PTFE-filled or composite pneumatic wear bands for better thermal stability and friction resistance. Similarly, modern polyurethane pneumatic piston seals outlast traditional rubber compounds. These advanced materials reduce energy loss and maintain flexibility across wider temperature ranges.

2. Perform Scheduled Pneumatic Cylinder Repair

Routine maintenance includes:

- Checking wear band thickness

- Replacing rod seals

- Inspecting cylinder bores

- Measuring stroke accuracy

- Lubricating guide bushings

These prevent surprise failures. Use predictive maintenance software to schedule these checks automatically.

3. Filter and Dry Your Air Supply

Install high-quality filters and dryers to protect against abrasive contaminants. This extends the life of both seals and internal bore surfaces. Invest in modular filter-regulator-lubricator (FRL) systems to ensure air quality is continuously controlled.

4. Use Lubrication Wisely

Some systems benefit from air-line lubrication. Others require dry operation with self-lubricating pneumatic wear bands. Know what your setup demands. Over-lubrication can attract dust, while under-lubrication can cause dry running.

5. Avoid Misalignment

Ensure proper mounting of actuators. Even a slight offset can cause uneven seal wear and side loading on guide rings. Use precision alignment tools during installation and verify periodically.

6. Monitor Cycle Speeds

Fast cycling increases heat and friction. If possible, reduce stroke frequency or allow for cooling intervals between rapid actuations.

7. Design for Serviceability

Incorporate features that make pneumatic cylinder repair faster, like modular end caps or quick-disconnect fittings. This encourages timely maintenance and less downtime.

The ROI of Wear Protection

Investing in quality pneumatic wear bands and preventive pneumatic cylinder repair lowers:

- Downtime from unscheduled repairs

- Compressed air energy loss

- Replacement costs from full cylinder rebuilds

Well-maintained systems last 2–3 times longer and perform consistently over their service life. In high-throughput facilities, even a 1% gain in equipment uptime translates to significant annual cost savings.

Innovations in Wear Protection Technology

- Smart Seals: Embedded sensors that monitor wear rate and performance.

- Composite Wear Bands: Mix of PTFE and fiberglass for high-load applications.

- Low-Friction Coatings: Applied to pneumatic piston seals to minimize heat.

- Rapid-Change Repair Kits: Modular systems allow fast, on-site pneumatic cylinder repair.

- Additive Manufacturing: 3D-printed wear parts tailored for custom or legacy systems.

These emerging technologies are revolutionizing how engineers approach pneumatic maintenance and system longevity.

Training and Best Practices

Technician training is a crucial part of wear prevention. Make sure your team knows:

- How to inspect and replace pneumatic wear bands

- The signs of worn pneumatic piston seals

- Correct torque specs during reassembly

- Proper cleaning and handling of seals during installation

Develop checklists for routine inspections and provide refresher training quarterly to keep skills sharp.

Conclusion

Wear is inevitable, but failure isn’t. Proactive use of pneumatic wear bands, timely pneumatic cylinder repair, and high-quality pneumatic piston seals ensure your pneumatic systems deliver reliable performance, cycle after cycle. Investing in wear protection is not just a maintenance decision—it’s a productivity strategy.

From food processing to packaging automation, every industry that relies on compressed air systems can benefit from smarter wear management. Take the time today to assess your maintenance program, upgrade your components, and implement regular checks.

Because when it comes to pneumatic systems, a small amount of wear prevention can yield huge returns in system uptime, safety, and cost control.