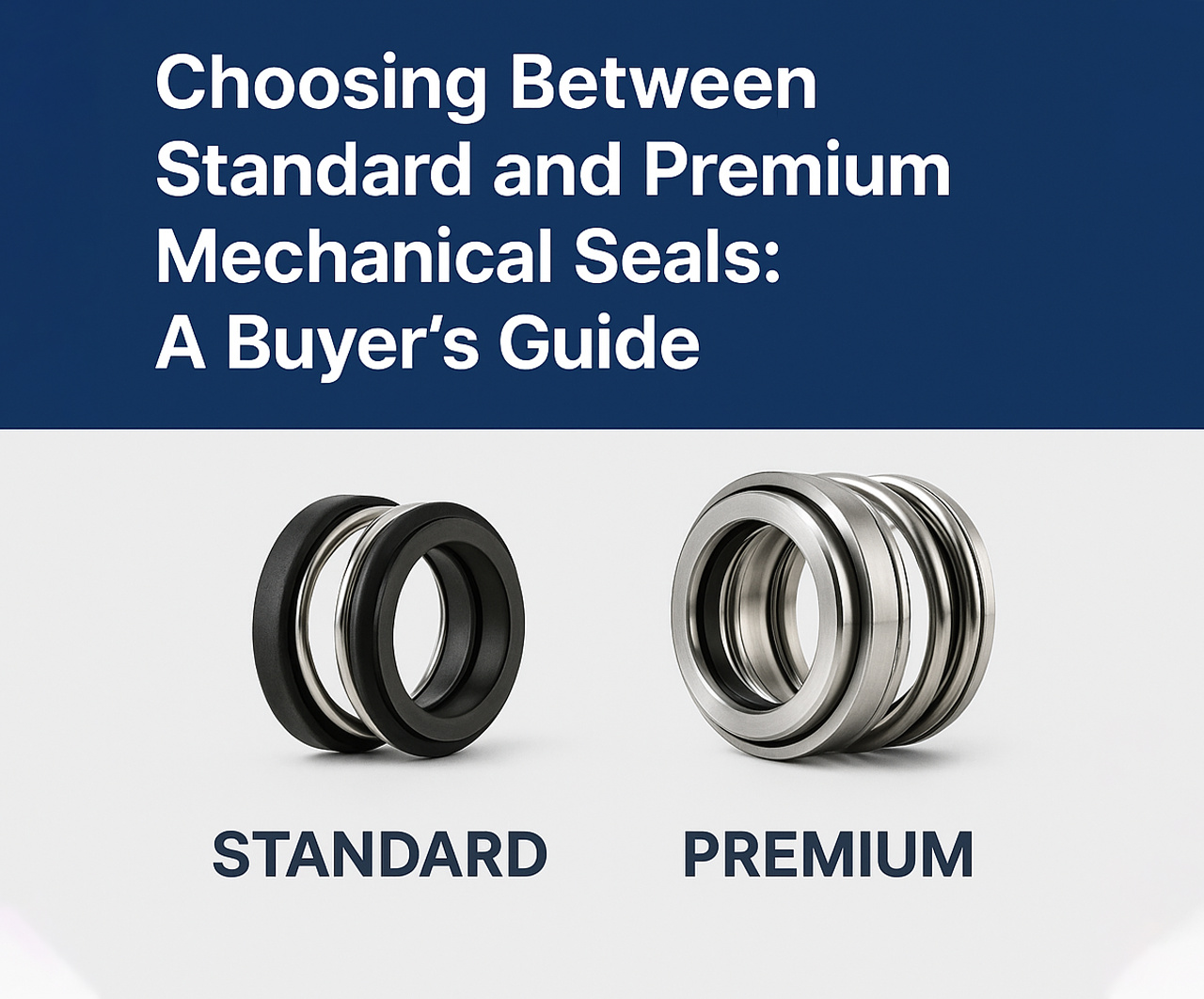

When specifying seals for industrial equipment, especially rotating machinery, it’s crucial to understand the performance difference between standard and premium premium mechanical seals, particularly as they relate to different types of mechanical seals for pumps and the demands of a centrifugal pump mechanical seal. Whether you’re maintaining a utility system or designing a high-performance production line, the wrong seal can lead to leakage, downtime, and expensive repairs. But with the right information, you can confidently choose between off-the-shelf options and engineered solutions. Know more..

Understanding the Basics: What Are Mechanical Seals?

Mechanical seals are devices that help join systems or mechanisms together by preventing leakage, containing pressure, and excluding contaminants. In rotating equipment such as pumps, mixers, and compressors, mechanical seals maintain the integrity of the system under both pressure and motion.

The core of any mechanical seal is the mechanical face seal: two flat, polished surfaces that press against each other to form a tight seal. One face is stationary (usually connected to the housing) and the other rotates with the shaft. The seal is maintained by spring force and hydraulic pressure.

Standard vs. Premium: Key Differences

| Feature | Standard Mechanical Seal | Premium Mechanical Seal |

| Material Composition | Basic elastomers and metals | Advanced alloys and ceramics |

| Application Tolerance | Normal operating conditions | High pressure, temperature, speed |

| Design Complexity | Single spring or basic pusher | Multi-spring, cartridge-based |

| Lifecycle Expectancy | Moderate | Extended with less maintenance |

| Cost | Lower upfront cost | Higher investment, lower downtime |

Standard mechanical seals are adequate for consistent, clean environments. But in applications where temperature, chemical exposure, or pressure fluctuate, premium mechanical face seals offer superior durability and resilience.

A Deep Dive Into Types of Mechanical Seals for Pumps

Pumps are among the most common machines that require sealing, and the types of mechanical seals for pumps vary based on duty and design:

1. Pusher Seals

These use a secondary sealing element that moves with the shaft. They are common in centrifugal pump mechanical seal systems but can suffer from wear in high-pressure conditions.

2. Non-Pusher Seals

With stationary secondary seals, they perform better in high-pressure and high-temperature environments. Often seen in premium applications.

3. Balanced Seals

Designed to reduce face load and allow operation at higher pressures. Essential for chemically aggressive or hot fluids.

4. Unbalanced Seals

Suitable for lower-pressure applications; typically used in water and HVAC systems.

5. Cartridge Seals

These come preassembled and pre-set, minimizing installation errors. Often the hallmark of premium centrifugal pump mechanical seal packages.

When Standard Mechanical Seals Make Sense

Choosing a standard seal is a smart move when:

- Operating under moderate temperature and pressure

- Pumping clean, non-corrosive fluids

- Replacing seals in legacy systems

- Budget constraints are top priority

Standard mechanical face seals are easy to find, cost-effective, and sufficient for utility pumps, irrigation systems, or simple wastewater setups.

When Premium Seals Are Worth the Investment

Premium seals are engineered for performance and endurance. You should choose them when:

- Your equipment runs continuously or in extreme environments

- You’re processing chemicals, slurries, or high-viscosity fluids

- There’s limited access for frequent maintenance

- Any seal failure leads to high costs or safety risks

In these cases, premium centrifugal pump mechanical seal systems pay off in uptime and performance.

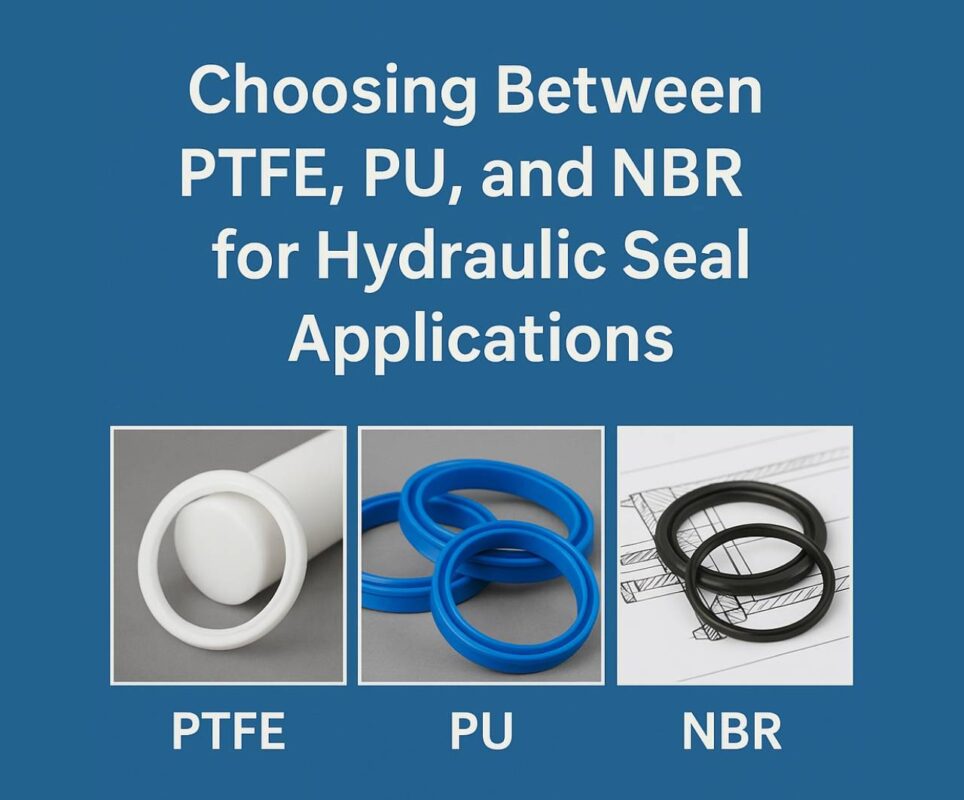

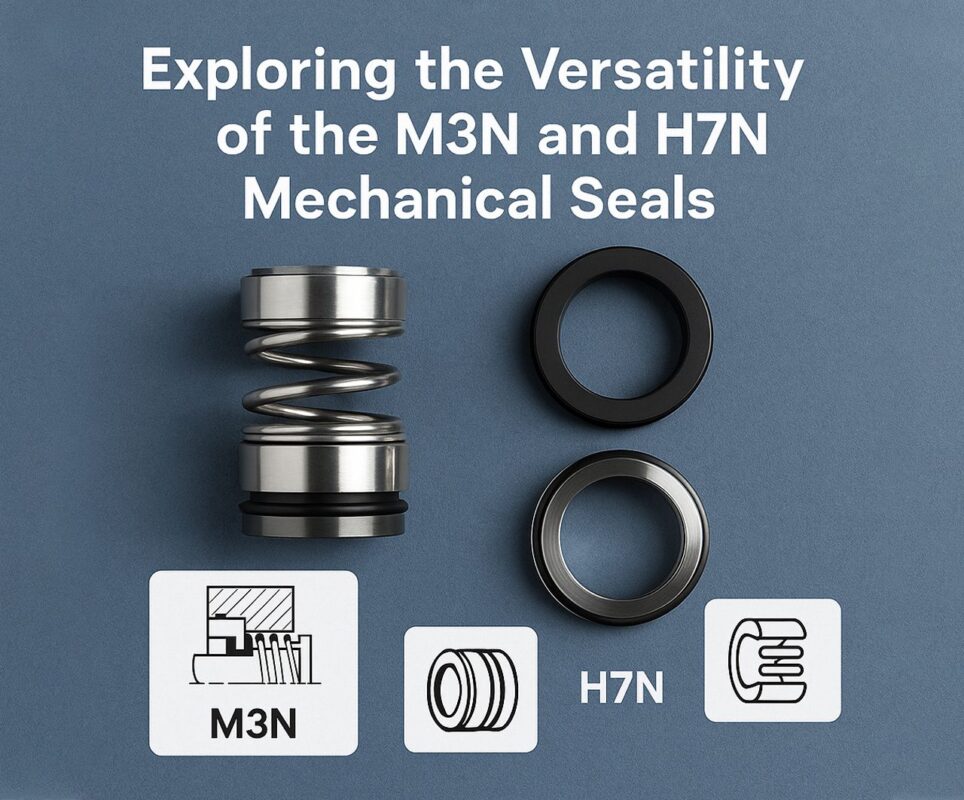

Mechanical Face Seal Material Comparison

Material choice greatly influences seal reliability:

- Carbon/Graphite: Low friction; good in water-based applications

- Silicon Carbide: Hard, wear-resistant, chemical-resistant (ideal for premium use)

- Tungsten Carbide: Durable under extreme wear and vibration

- Ceramic: Corrosion-resistant and cost-effective for moderate use

Premium seals typically combine Silicon Carbide or Tungsten faces with advanced elastomers like FKM or PTFE.

Application-Specific Examples

1. Municipal Water Pumps

Use standard mechanical face seals that are easy to install and replace. Cost is a concern, and the media is non-corrosive.

2. Chemical Processing Plant

A premium cartridge centrifugal pump mechanical seal is ideal due to high temperatures, aggressive media, and continuous duty cycles.

3. Food and Beverage Industry

Premium seals with FDA-grade elastomers prevent contamination and survive washdown cycles.

4. Mining Slurry Pumps

Require robust, balanced mechanical face seals to handle high solids content and abrasive fluids.

Installation and Maintenance Tips

Whether using standard or premium options:

- Follow manufacturer specs: Installation torque, spring pressure, and alignment are critical.

- Clean thoroughly: Foreign debris during install can destroy a seal.

- Check shaft condition: Scored or pitted shafts reduce seal life.

- Use flush plans when needed: Especially in high-temperature or slurry applications.

Cost vs. Value: Doing the Math

Premium seals might cost 2–3x more than standard ones. But consider:

- Longer time between replacements

- Less downtime and labor

- Fewer emergency repairs

- Better process control and product quality

In many cases, premium types of mechanical seals for pumps are more economical in the long run.

What to Ask When Choosing a Seal

- What fluid is being sealed?

- What are the pressure and temperature ranges?

- Is the application static or dynamic?

- How often can the equipment be maintained?

- What are the consequences of failure?

These answers help determine whether a standard or premium centrifugal pump mechanical seal fits your operation.

Top Mechanical Seal Suppliers to Consider

Look to trusted names for quality and support:

- John Crane

- AESSEAL

- Flowserve

- EagleBurgmann

These companies offer everything from standard O-ring pusher seals to advanced dual cartridge premium solutions.

Looking Ahead: Smart Seals and Digital Monitoring

The future of mechanical face seals includes:

- Smart sensors to monitor wear, temperature, and leakage

- Wireless alerts for predictive maintenance

- AI integration to optimize seal selection and lifecycle analysis

These technologies are already appearing in premium centrifugal pump mechanical seal packages.

Final Thoughts: Don’t Just Buy a Seal—Buy Confidence

Choosing between standard and premium mechanical seals isn’t about cost alone. It’s about aligning your selection with the demands of your equipment, your operational goals, and your risk tolerance.

If you’re running a basic water pump on a tight budget, a standard option may do the trick. But if uptime, safety, and performance are non-negotiable, investing in a premium mechanical face seal or specialized types of mechanical seals for pumps is the smarter choice.

In sealing systems, as in engineering, you usually get what you pay for. So choose wisely—and seal the deal on your system’s reliability.