Built for Pressure, Designed for Precision | ID≤2000mm Oil Resistance O Ring Seal Construction Machinery

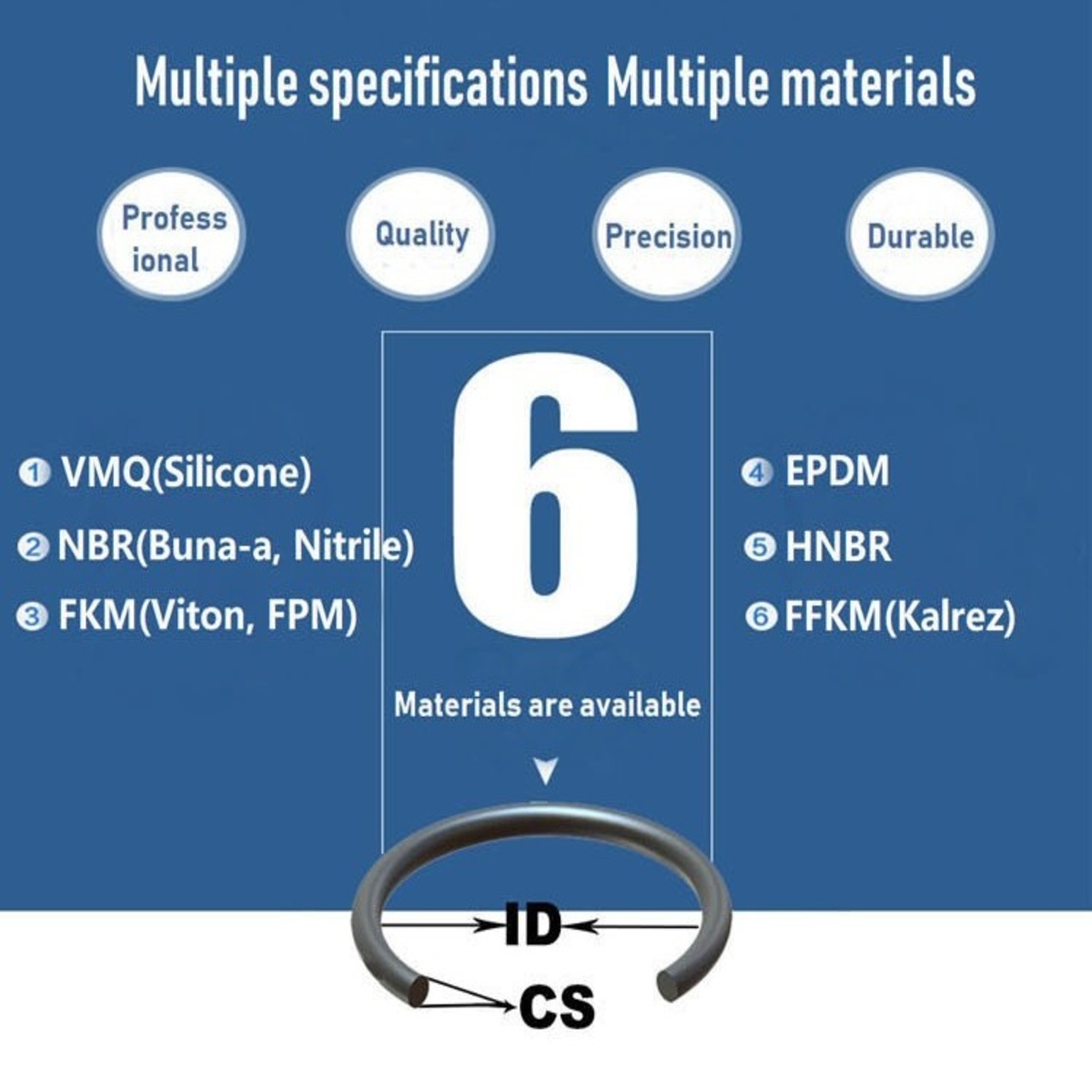

The ID≤2000mm Oil Resistance O Ring Seal is engineered for robust sealing in hydraulic systems exposed to oil, pressure, and extreme environmental stress. Designed specifically for construction machinery and heavy-duty equipment, these O-rings deliver outstanding oil resistance and dimensional stability across a broad range of operating temperatures. Made from premium o ring rubber materials such as NBR, FKM, and HNBR, they ensure long-lasting performance in dynamic and static sealing applications. With ID sizes up to 2000mm, they are ideal for large-scale equipment requiring durable and flexible sealing solutions.

Product Specifications

| Material | Hardness (Shore A) | Temperature Range | Standard Size | Resistance | Color | Application |

|---|---|---|---|---|---|---|

| NBR (Buna, Nitrile) | 60–90 | -40℃ to 110℃ | AS-568 (USA), JIS-B2401 (Japan), DIN-3771 (Germany), BS-1516 (UK), ISO3601 (International), R (France) ID ≤ 2000mm, CS ≤ 40mm |

Hydraulic Fluid, Engine Oil, Chemical, Ozone & UV, Steam & Hot Water, Low Temperature, High Temperature | Black, Brown, Red, Green, White, Blue, Clear, Customized | Auto Industry, Construction Machinery, Machine Tool Equipment, Food Health, Water Treatment, Chemical Processing, Hydraulic Pneumatic, Industrial Manufacturing |

| FKM (FPM) | 70–90 | -20℃ to 220℃ | ||||

| EPDM | 60–90 | -45℃ to 150℃ | ||||

| Silicone (VMQ) | 40–70 | -55℃ to 204℃ | ||||

| HNBR | 60–90 | -48℃ to 180℃ | ||||

| FFKM (Kalrez) | 70–90 | -18℃ to 326℃ |

Why Choose ID≤2000mm Oil Resistance O Ring Seal Construction Machinery?

🔹 Wide inner diameter range—up to 2000mm—for large hydraulic systems

🔹 Excellent oil resistance for use with engine oil, hydraulic fluid, and lubricants

🔹 Made from high-grade o ring rubber materials like NBR, FKM, and HNBR

🔹 Suitable for dynamic and static applications in construction machinery

🔹 Performs reliably across varying temperatures and pressures

🔹 Customizable cross-section sizes up to 40mm for a perfect fit

🔹 Designed to resist wear, heat, and chemical degradation

🔹 Simple to install and fits industry standard sealing grooves

🔹 Ideal for OEM manufacturing and replacement in heavy equipment

🔹 Prevents leaks, enhances sealing integrity, and reduces maintenance

Application of ID≤2000mm Oil Resistance O Ring Seal Construction Machinery

🔹 Excavators & Loaders – Seals hydraulic joints and components in high-pressure oil systems

🔹 Cranes & Bulldozers – Provides leak-proof operation in large bore cylinder applications

🔹 Agricultural Equipment – Used in tractors, plows, and sprayers for sealing hydraulic fluid paths

🔹 Mining Machinery – Resists abrasion and chemicals in harsh mining environments

🔹 Water Treatment & Industrial Plants – Seals rotating and static components exposed to oils and fluids

🔹 Heavy Manufacturing & Press Machines – Maintains reliable sealing in high-speed hydraulic press systems

Order Now – Get Your ID≤2000mm Oil Resistance O Ring Seal Construction Machinery Today!

Upgrade your hydraulic systems with the ID≤2000mm Oil Resistance O Ring Seal, specifically developed to meet the rigorous demands of construction and industrial applications. Built with oil-resistant compounds and precision-engineered to fit a wide range of grooves, these O-rings offer long-term sealing reliability in oil-based systems. Whether you’re sourcing for OEM production or upgrading existing systems, these oil-resistant O-ring seals ensure lasting protection, minimal maintenance, and high operational efficiency. Trust this heavy-duty solution to maintain seal integrity and performance in your toughest environments.