Built for Hygiene, Designed for Safety | Top Sale Food Grade Seal Washer Custom Rubber Gasket Seal

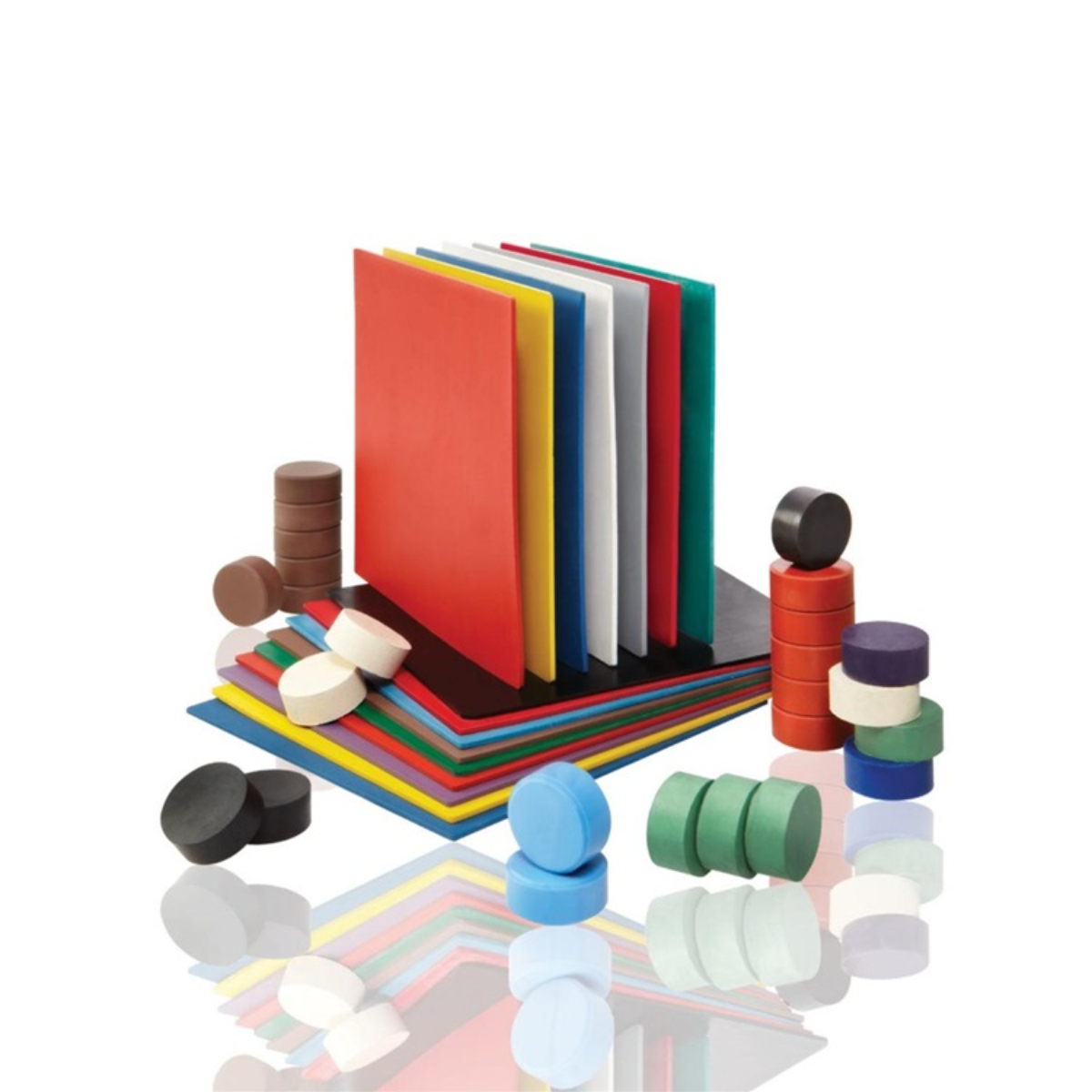

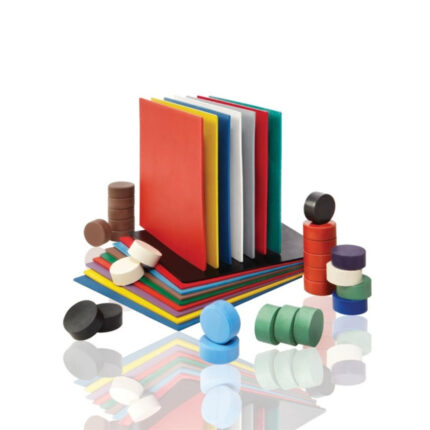

The Top Sale Food Grade Seal Washer Custom Rubber Gasket Seal is expertly crafted to meet the strict safety and hygiene standards required in food and beverage, pharmaceutical, and cleanroom environments. Constructed from high-quality food-grade rubber materials like silicone and EPDM, this gasket seal offers excellent elasticity, temperature resistance, and chemical compatibility. Its precision-molded design ensures a reliable seal in static and dynamic applications, helping prevent contamination and leakage. Whether you’re sealing piping systems, tanks, or machinery components, this washer delivers reliable performance where cleanliness is critical.

Its customizability in shape, size, and hardness allows it to adapt precisely to different sealing surfaces, reducing system failures caused by wear, improper fit, or temperature fluctuations. Designed to handle oil, heat, and moisture exposure, this gasket performs reliably through frequent washdowns and high-temperature processes. Its non-toxic and odorless rubber composition ensures a clean sealing solution suitable for sensitive environments. With long service life and superior flexibility, this washer is an ideal choice for maintaining tight, hygienic seals in food-related and industrial applications.

Product Specifications

| Attribute | Details |

|---|---|

| Product Name | Top Sale Food Grade Seal Washer Custom Rubber Gasket Seal |

| Material Type | Rubber |

| Color | Brown |

| Hardness | 30–90 Shore |

| Temperature | -60℃ to 260℃ |

| Feature | Waterproof, Oil Resistant, Heat Resistant |

| Application | All Industry |

Why Choose Top Sale Food Grade Seal Washer Custom Rubber Gasket Seal?

🔹 Made from FDA-compliant, food-safe rubber materials

🔹 Excellent resistance to oils, acids, and high temperatures

🔹 Designed for precision sealing in food and sanitary systems

🔹 High flexibility and compression recovery for leak prevention

🔹 Durable and tear-resistant even under repeated pressure

🔹 Customizable shapes, sizes, and durometers for various uses

🔹 Compatible with both metal and plastic flanges

🔹 Non-toxic, odorless, and easy to clean for hygiene-sensitive settings

🔹 Maintains sealing performance in hot water, steam, and CIP processes

🔹 Trusted choice for food processing, pharma, and water systems

Application of Top Sale Food Grade Seal Washer Custom Rubber Gasket Seal

🔹 Food & Beverage – Used in bottling lines, mixers, tanks, and filling machines for sanitary-grade sealing

🔹 Pharmaceuticals – Ensures contamination-free sealing in drug manufacturing and cleanroom systems

🔹 Water Treatment – Prevents leaks in purification systems and potable water piping

🔹 Dairy & Brewing – Ideal for use in high-hygiene dairy pipelines, breweries, and fermenters

🔹 Packaging Equipment – Used in sealing elements of food-grade machinery

🔹 Kitchen Appliances – Applied in blenders, juicers, coffee machines, and more

Order Now – Get Your Top Sale Food Grade Seal Washer Custom Rubber Gasket Seal Today!

Upgrade your operations with a dependable, food-grade sealing solution designed for safety and performance. The Top Sale Food Grade Seal Washer Custom Rubber Gasket Seal delivers consistent sealing strength, long life, and ease of maintenance. Whether you’re working with high heat, steam, or chemical agents, this gasket provides optimal protection while keeping your system sanitary and efficient. Choose quality that keeps your production safe and compliant—built to meet today’s strict industry standards.

With superior resistance to water, oil, and temperature extremes, this rubber gasket seal is an ideal fit for demanding sealing challenges in processing equipment, pipelines, or pressure vessels. Its adaptable design supports both custom and standard applications, helping reduce downtime and ensuring dependable sealing even under repeated stress. Backed by premium rubber compounds and precision molding, it delivers a leak-free experience across a variety of industrial environments. Rely on this seal washer to enhance performance, minimize maintenance, and support hygienic operations for the long term.