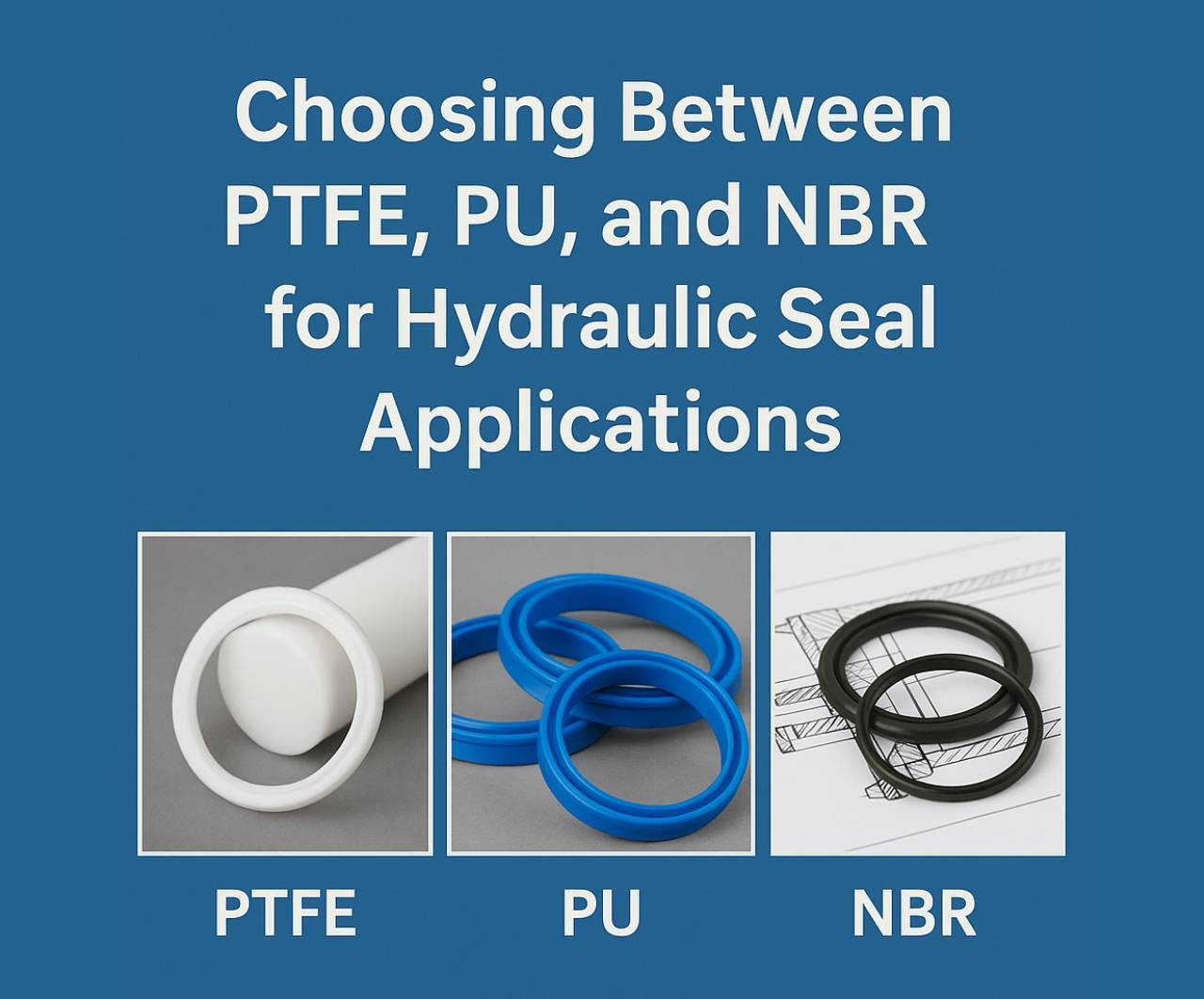

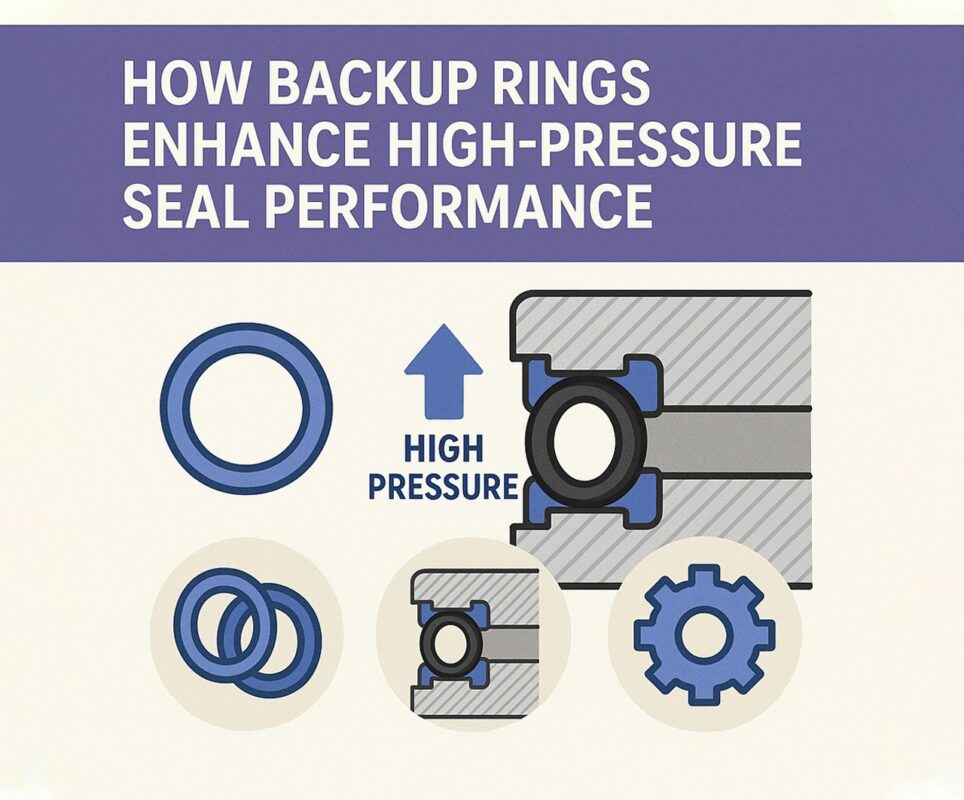

When it comes to maintaining efficiency, leak prevention, and durability in hydraulic systems, the right seal material can make all the difference. Whether you’re overhauling hydraulic jack seals, selecting a replacement hydraulic pump shaft seal, or sourcing reliable hydraulic motor shaft seals for a demanding job site, material choice is a critical factor that directly impacts equipment performance and lifespan. The three most popular material options—PTFE, PU, and NBR—each offer unique advantages and drawbacks depending on the application.

In this guide, we’ll break down the properties of each, explore where they excel, and help you make a smarter, more reliable choice for your next hydraulic project. Know more..

Why Material Selection Matters for Hydraulic Seals

Hydraulic systems rely on seals to contain pressurized fluids, prevent contamination, and withstand tough operating conditions like extreme temperatures, high pressures, and exposure to aggressive fluids. The material composition of a hydraulic jack seals, hydraulic pump shaft seal, or hydraulic motor shaft seals determines how well it handles these demands.

An ill-suited seal material can cause leaks, increased friction, rapid wear, and eventually, catastrophic equipment failure. Matching the material to the system’s pressure, fluid type, and temperature range is essential for both performance and cost control. With today’s equipment operating faster and longer than ever, the seal’s job has become increasingly complex—and selecting the right one is a balancing act between performance, durability, and budget.

PTFE (Polytetrafluoroethylene) Seals: Low-Friction Performance

PTFE is a synthetic fluoropolymer known for its low-friction properties, chemical inertness, and high-temperature tolerance.

Ideal for:

- High-speed rotary hydraulic motor shaft seals

- Aggressive fluid systems (acids, fuels, chemicals)

- Wide temperature ranges (-60°C to +200°C)

Advantages:

- Extremely low coefficient of friction

- Excellent chemical resistance

- Non-stick properties prevent adhesion to mating surfaces

- Outstanding thermal stability

- Minimal absorption of fluids, reducing swelling or distortion

Limitations:

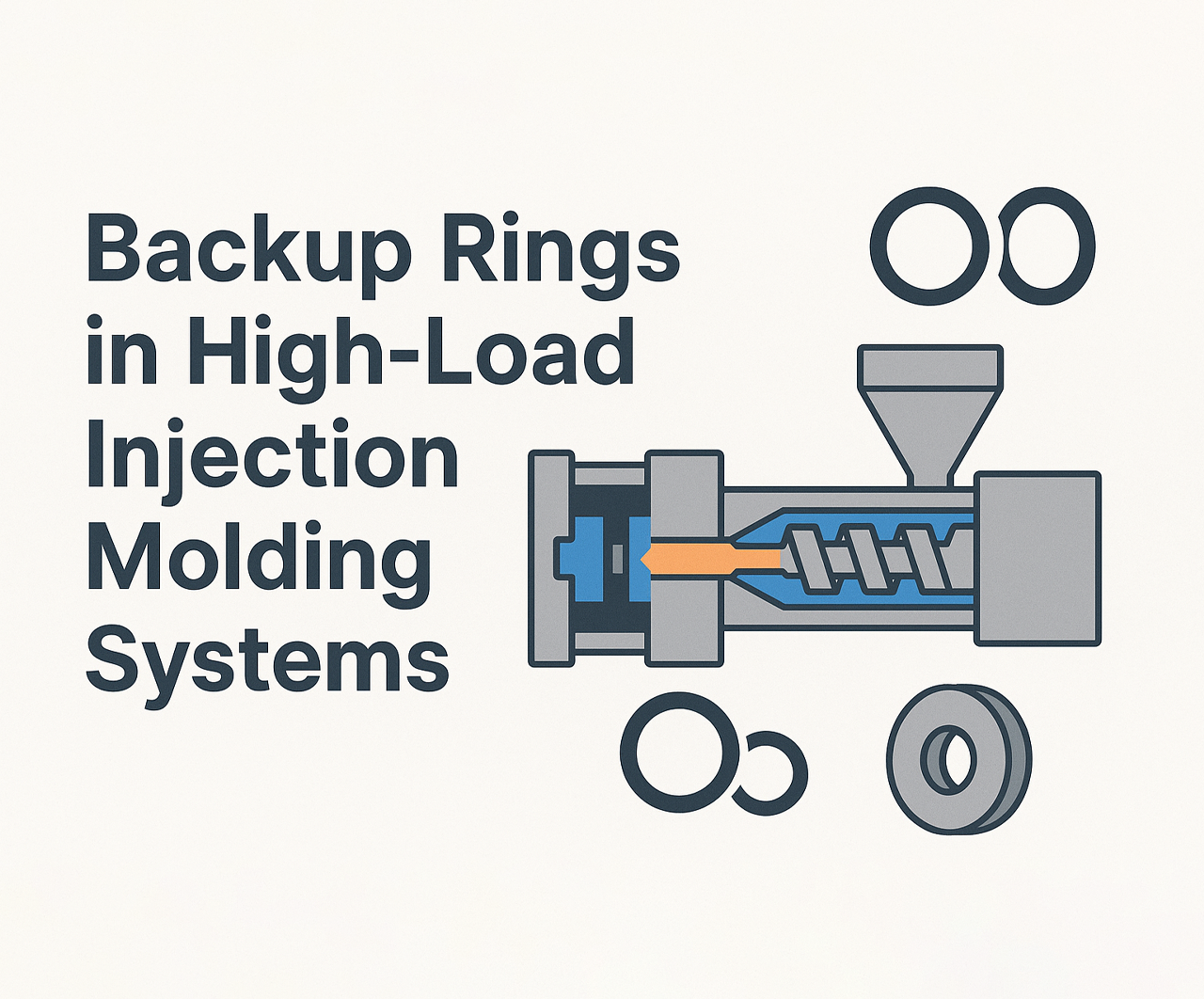

- Brittle under dynamic loads

- Poor elastic recovery (requires back-up rings or energizers)

- Not ideal for heavy-duty hydraulic jack seals exposed to frequent shock loads

Pro Tip: PTFE is often blended with fillers like bronze, glass, or carbon to improve wear resistance and load capacity for hydraulic pump shaft seal and rotary applications. Engineers should consult with suppliers on the best blend for their operating environment.

PU (Polyurethane) Seals: Tough and Wear-Resistant

PU is one of the most popular materials for dynamic hydraulic seals due to its balance of strength, flexibility, and wear resistance.

Ideal for:

- High-pressure hydraulic jack seals

- Reciprocating piston and rod seals

- Outdoor and mobile equipment applications

Advantages:

- Excellent abrasion and extrusion resistance

- Good tensile strength and tear resistance

- Withstands high-pressure spikes

- Performs reliably in temperatures from -30°C to +100°C

- Long-lasting in outdoor and mobile equipment applications

Limitations:

- Limited chemical resistance (susceptible to acids, solvents, and hydrocarbons)

- Lower heat resistance compared to PTFE

Pro Tip: PU seals offer longer life in high-cycle applications like hydraulic motor shaft seals exposed to repetitive, heavy-duty loads. In high-speed rotary systems, pairing PU with wear rings can help reduce side loads on the seal.

NBR (Nitrile Butadiene Rubber) Seals: Versatile and Affordable

NBR remains one of the most widely used elastomers in hydraulic sealing because of its affordability and versatility.

Ideal for:

- General-purpose hydraulic pump shaft seal and rod seals

- Low to medium pressure systems

- Applications with exposure to oils and water-based fluids

Advantages:

- Good oil, fuel, and water resistance

- Flexible and easy to install

- Cost-effective for large-scale or OEM production

- Reliable performance from -30°C to +100°C

- Compatible with most petroleum-based hydraulic fluids

Limitations:

- Poor resistance to ozone, weathering, and acids

- Limited wear and extrusion resistance under high pressure

- Shorter lifespan in continuous dynamic applications compared to PU and PTFE

Pro Tip: For aggressive operating conditions, consider hydrogenated nitrile (HNBR), which improves high-temperature and chemical resistance in hydraulic motor shaft seals while retaining NBR’s affordability.

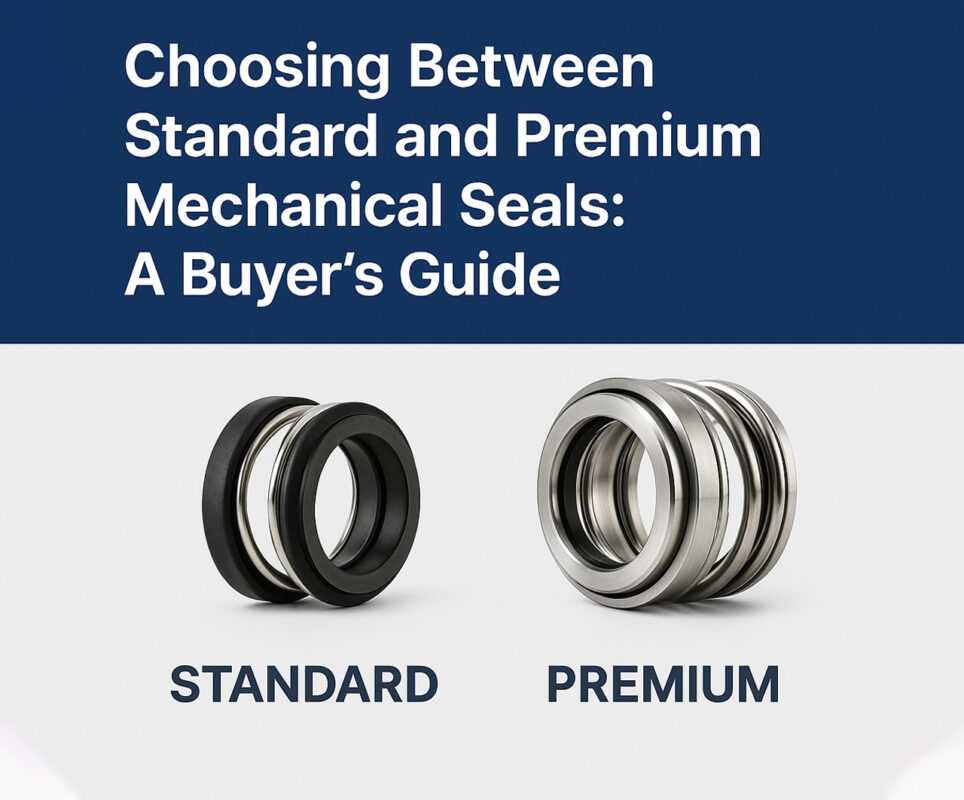

Comparing PTFE, PU, and NBR for Key Hydraulic Applications

| Application | PTFE | PU | NBR |

| Hydraulic Jack Seals | Good (with backup) | Excellent | Good |

| Hydraulic Pump Shaft Seal | Excellent (chemical) | Good | Good (general use) |

| Hydraulic Motor Shaft Seals | Excellent (high-speed) | Very Good | Good (light-duty) |

| High-Pressure Performance | Moderate | Excellent | Moderate |

| Abrasion/Extrusion Resistance | Moderate | Excellent | Low |

| Chemical Resistance | Excellent | Moderate | Good |

| Temperature Range | -60°C to +200°C | -30°C to +100°C | -30°C to +100°C |

New Ideas: Composite and Hybrid Seals

Seal manufacturers are increasingly blending materials to create hybrid solutions that overcome individual weaknesses. For example:

- PTFE seals with elastomer energizers combine chemical resistance with improved elasticity.

- PU outer rings with NBR sealing lips improve wear resistance while retaining cost-efficiency.

- Multi-material hydraulic jack seals for mobile cranes combine HNBR lips with PU wear rings for high-pressure, high-cycle conditions.

- Carbon-filled PTFE is gaining ground in ultra-high-speed hydraulic motor shaft seals because it improves thermal conductivity and reduces frictional heat.

These hybrid designs extend service life and improve performance in mixed-duty or highly variable environments.

Sustainability and Material Selection

Sustainable practices are reshaping hydraulic sealing:

- Recyclable PU formulations are reducing environmental impact.

- Bio-based NBR alternatives offer lower carbon footprints.

- Long-life hydraulic motor shaft seals made from advanced PTFE blends reduce waste by minimizing replacement frequency.

Investing in long-lasting materials helps cut operating costs and meets tightening environmental regulations. OEMs increasingly favor seals designed for longer service intervals to minimize environmental impact and disposal challenges.

Field Performance Factors Beyond Material

While material choice is vital, installation and maintenance practices also influence seal longevity:

- Hydraulic pump shaft seal performance improves with careful shaft surface preparation and regular oil analysis.

- Hydraulic jack seals should be matched to equipment cycle rates, with periodic wear ring inspections.

- Hydraulic motor shaft seals experience longer life when paired with clean, well-filtered hydraulic fluids and appropriate shaft finish specifications.

Training maintenance teams on best installation practices dramatically extends seal performance, especially for delicate PTFE seals prone to damage during assembly.

Best Practices for Seal Selection

- Define system parameters: Pressure, temperature, speed, fluid type, and expected cycle rates.

- Prioritize critical properties: Focus on abrasion resistance for hydraulic jack seals and chemical compatibility for hydraulic pump shaft seal applications.

- Consider installation factors: Ease of assembly, field replacement speed, and retrofit options.

- Review total lifecycle cost: Balance operational efficiency, maintenance frequency, and upfront seal pricing.

- Collaborate with expert suppliers: Prioritize those offering tailored recommendations, prototype options, and technical support.

Final Thoughts

Choosing between PTFE, PU, and NBR for hydraulic jack seals, hydraulic pump shaft seal, and hydraulic motor shaft seals isn’t just a technical decision—it’s a strategic move that impacts operational uptime, maintenance budgets, and system longevity.

For chemically aggressive or high-temperature applications, PTFE shines. PU dominates high-pressure, abrasive settings, while NBR remains a cost-effective all-rounder for general use. Blended and hybrid seals represent the next evolution, offering improved durability, extended performance ranges, and better environmental sustainability.

A smart seal choice ensures hydraulic systems stay leak-free, efficient, and productive—even in the toughest industrial environments. As equipment demands evolve and regulatory pressures rise, seal material innovation and precise application matching will remain central to hydraulic system reliability. Know more..