In industries that rely on high-performance machinery, seal integrity is non-negotiable. Equipment downtime not only disrupts operations but can also lead to expensive repairs and safety risks. That’s why recognizing early signs of seal failure—especially in critical components like the ah22401 oil seal, ah22401 seal, and gaco dpsm 12247 seal—is essential. These seals are part of the widely used Series 224 family, which operates in challenging environments where reliability matters. Failing to detect seal degradation early can lead to fluid leakage, contamination, and even catastrophic equipment failure.

In this guide, we’ll explore how to identify seal failures in Series 224, with a special focus on the ah22401 oil seal, ah22401 seal, and gaco dpsm 12247 seal, and offer expert tips on how to prevent costly downtime through proactive maintenance, diagnosis, and replacement strategies. Know more..

Why the Series 224 Matters in Industrial Applications

The Series 224 seal family, including the ah22401 oil seal and gaco dpsm 12247 seal, is commonly used in power transmission systems, rotating shafts, gearboxes, pumps, and agricultural machinery. These seals provide crucial barriers between moving components and the external environment, preventing oil leaks and contamination ingress.

Among them:

- The ah22401 seal is known for its high-performance profile in extreme-pressure environments.

- The ah22401 oil seal is engineered to retain lubrication while resisting degradation due to temperature fluctuations or chemical exposure.

- The gaco dpsm 12247 seal is valued for its dual-lip design, making it ideal for harsh conditions like dust, mud, and abrasive media.

All these seals share a common challenge: they must perform continuously under stress, and any failure can compromise an entire system.

Early Warning Signs of Seal Failure

Failing to detect early symptoms of a compromised ah22401 seal or gaco dpsm 12247 seal can lead to a full-blown mechanical disaster. Here’s what to look for:

1. Visible Oil Leaks

Perhaps the most obvious red flag, oil collecting around the housing area usually points to a broken or worn ah22401 oil seal. Leaks should never be ignored—even small drips signal a weakening seal.

2. Discoloration or Burn Marks

Excessive heat causes seals to harden, crack, or shrink. If the ah22401 seal or gaco dpsm 12247 seal is exposed to elevated temperatures, visual cues like discoloration or burnt edges may appear during inspection.

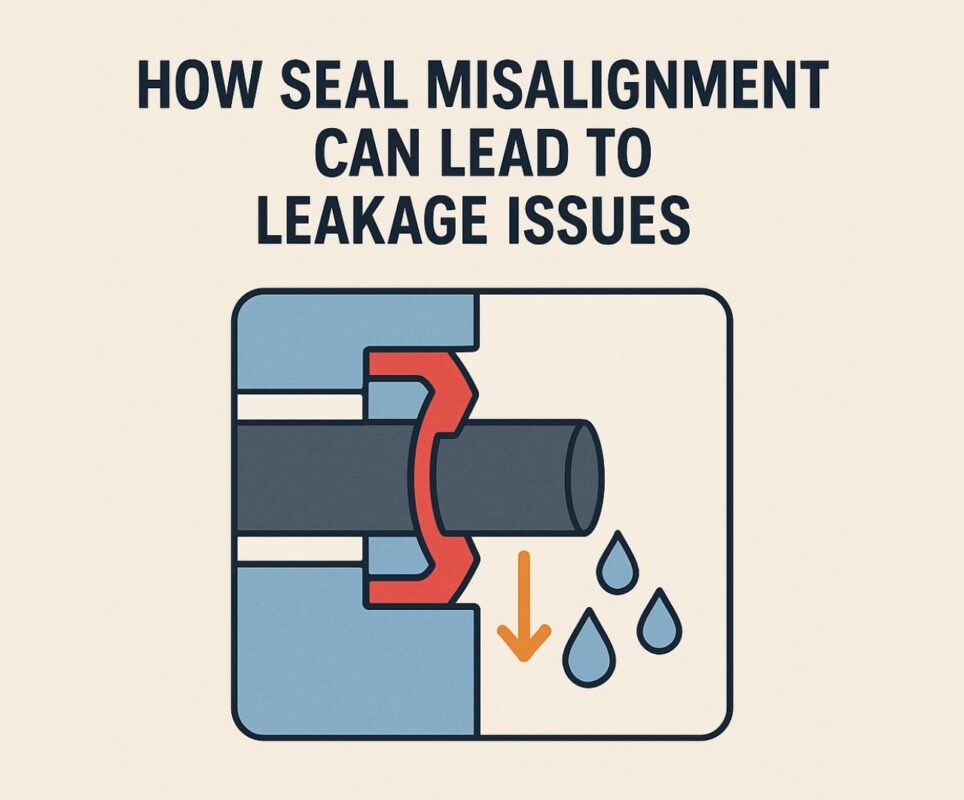

3. Unusual Noises or Vibrations

An improperly seated ah22401 oil seal can introduce misalignment in rotating shafts, leading to irregular sounds, increased vibration, or even bearing failure.

4. Contamination in Oil

If you find metal particles, dirt, or water in your lubricating oil, it likely entered through a damaged or failed gaco dpsm 12247 seal. Poor sealing allows outside contaminants to infiltrate critical systems.

5. Deformation or Hardening

Rubber seals like the ah22401 seal can become brittle over time, especially when exposed to incompatible fluids or excessive heat. Physical inspection during maintenance may reveal hardening or loss of elasticity.

Common Causes of Seal Failure in Series 224

Understanding what leads to the failure of seals like the ah22401 oil seal or gaco dpsm 12247 seal can help you mitigate those risks early:

1. Improper Installation

Seals installed off-center or under too much torque can wear unevenly. This issue is especially common in the ah22401 seal, which is often used in high-speed shafts.

2. Incorrect Seal Material

Using a seal that isn’t chemically or thermally compatible with its operating environment shortens its lifespan. For instance, a standard nitrile ah22401 oil seal may fail prematurely if exposed to aggressive solvents or high heat.

3. Shaft Damage

Even microscopic shaft scratches or burrs can tear a gaco dpsm 12247 seal over time. The interaction between the seal lip and the shaft must be as smooth as possible.

4. Overpressure

Exceeding design pressure ratings causes the seal lip to lift or invert, breaking the barrier and allowing oil to escape. Both the ah22401 seal and gaco dpsm 12247 seal should always be checked for their maximum pressure specs.

5. Environmental Exposure

Seals exposed to UV, ozone, dirt, or water without proper shielding will degrade faster. This is a frequent issue in agricultural applications, where ah22401 oil seals are exposed to harsh field conditions.

Inspection Techniques to Detect Wear and Tear

Regular inspection of seals—especially the ah22401 seal and gaco dpsm 12247 seal—is critical to catching problems before they become serious. Use the following techniques during maintenance:

- Visual Inspection: Check for nicks, cracks, flat spots, and surface scoring.Tactile Testing: Gently flex the seal. If it doesn’t return to shape quickly or feels stiff, it may be degraded.

- Leak Testing: Use UV dye or a pressure leak test to identify small leaks around the ah22401 oil seal.

- Oil Sampling: Test oil for metal shavings, moisture, or other signs of contamination.

Preventative Strategies to Avoid Costly Downtime

Preventing downtime starts with a solid maintenance plan tailored to your seal type—especially when dealing with critical components like the ah22401 seal or gaco dpsm 12247 seal.

1. Seal Replacement Schedule

Don’t wait for a failure to act. Build a replacement schedule based on runtime, environmental exposure, and manufacturer recommendations.

2. Stock Critical Spares

Always keep spare ah22401 oil seals and gaco dpsm 12247 seals in stock for quick swaps during scheduled maintenance. Waiting for replacement parts during a failure adds days to your downtime.

3. Upgrade When Necessary

If you’re using an older design or a generic seal, consider upgrading to a higher-performance option like the ah22401 seal, which is designed to outperform standard seals under stress.

4. Use Shaft Protectors

Protective sleeves or shaft conditioners reduce wear on both the seal and shaft. This is especially useful in abrasive environments where gaco dpsm 12247 seal performance is tested to the limit.

5. Lubricate Before Install

Always pre-lubricate the seal lip and housing before installation. Dry installations lead to initial startup wear and reduce seal life.

The Role of Seal Design in Performance

The design of Series 224 seals like the ah22401 oil seal and gaco dpsm 12247 seal plays a major role in how well they perform under pressure. Here’s what makes these seals different:

- Dual-Lip Sealing: The gaco dpsm 12247 seal uses dual-lip technology for improved contamination control.

- Reinforced Shells: The ah22401 seal often includes a metal shell for better shape retention.

- Spring-Loaded Lips: These provide consistent sealing pressure, even as materials expand or contract under temperature changes.

Upgrading to engineered seals with advanced lip geometry and better material blends can drastically extend seal lifespan in demanding operations.

Industry-Specific Use Cases

Agriculture

The ah22401 oil seal is widely used in tractors and combines. Here, exposure to mud, debris, and UV makes seal performance crucial for uptime.

Mining and Construction

With high vibration, dust, and hydraulic pressure, the gaco dpsm 12247 seal provides rugged durability in haul trucks and drilling rigs.

Automotive

The ah22401 seal can be found in gearboxes and differentials, where its resistance to oil degradation ensures smooth operation over long distances.

Marine

In boats and marine engines, seals must withstand salt corrosion. High-end ah22401 oil seals with stainless reinforcement perform reliably in these harsh environments.

Final Thoughts

Detecting and preventing seal failure in Series 224 systems—especially with critical parts like the ah22401 oil seal, ah22401 seal, and gaco dpsm 12247 seal—is not just good maintenance; it’s a strategic move to safeguard productivity, safety, and equipment value.

By recognizing the warning signs early, using advanced inspection techniques, and adopting proactive prevention strategies, you can minimize downtime, extend component life, and save on costly emergency repairs.

The next time you’re evaluating the health of your equipment, start with the seals—those small components doing a big job in the background. Keeping your ah22401 seal or gaco dpsm 12247 seal in top shape might just be the smartest maintenance decision you make all year.