In the world of advanced engineering systems, performance under extreme conditions is not just a benchmark—it’s a necessity. Whether you’re dealing with deep-well oil rigs, jet engine components, or high-output industrial pumps, proper sealing ensures everything functions efficiently and safely. Critical to this performance is the geometry of the seal itself. When selecting materials and configurations for harsh environments, key factors include high temperature oil seals, hydraulic piston seals, and metal clad seals. These components, though often overlooked, play a pivotal role in the long-term stability of high-pressure and high-temperature machinery.

This article explores how optimizing seal geometry can significantly improve performance, reduce wear, and extend the service life of components exposed to extreme pressure and heat. Know more..

The High-Stakes Nature of Extreme Applications

High-pressure, high-temperature (HPHT) environments exist across a variety of industries:

- Oil & gas drilling

- Power generation

- Aerospace propulsion systems

- High-speed manufacturing equipment

Seals in these systems must withstand:

- Temperatures exceeding 200°C

- Pressures upwards of 10,000 psi

- Thermal cycling and vibration

- Fluid contamination and chemical exposure

Choosing the right high temperature oil seals, hydraulic piston seals, and metal clad seals ensures operational continuity and minimizes the risk of catastrophic failure.

The Importance of Seal Geometry

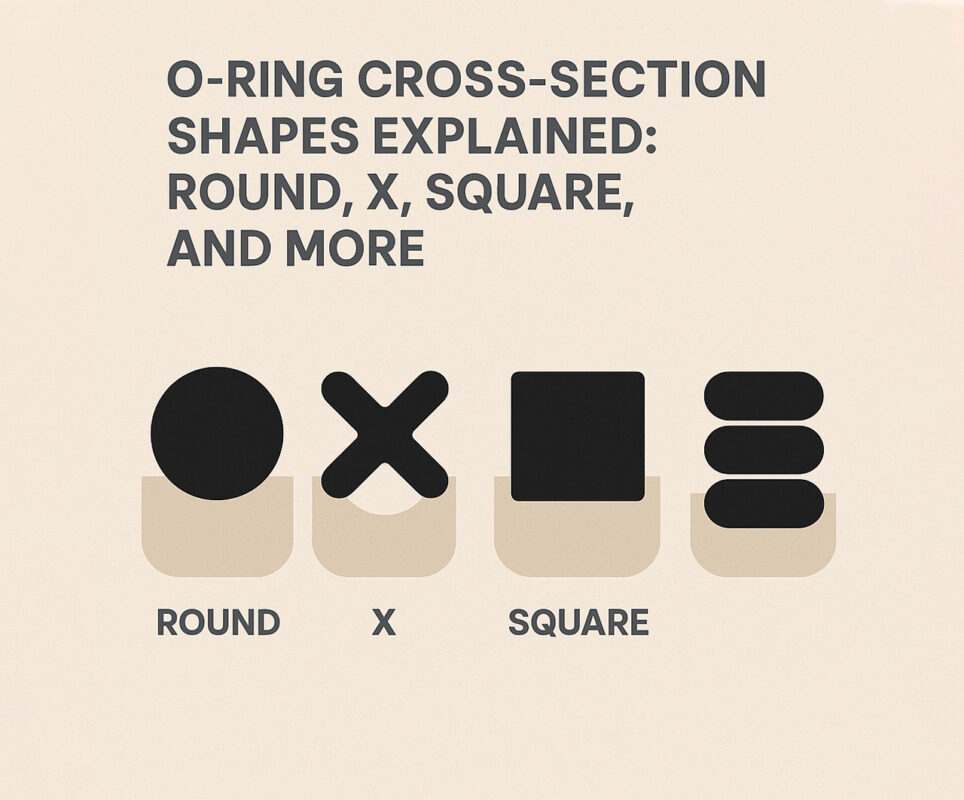

Geometry isn’t just about the shape of a seal. It involves:

- Contact angles

- Lip design

- Groove placement

- Cross-sectional profiles

Proper geometry balances the dynamic interaction between pressure, temperature, and movement. When optimized, seals offer:

- Superior extrusion resistance

- Stable compression force

- Reduced friction and wear

- Enhanced thermal performance

For instance, a modified U-cup design in a hydraulic piston seal can prevent blowouts under pressure spikes while minimizing stick-slip.

High Temperature Oil Seals: Resisting Thermal Breakdown

High temperature oil seals must resist degradation under continuous heat. Their geometry typically includes:

- Reinforced outer casings

- Inner elastomer lips with steel springs

- Secondary dust lip for contamination control

In applications like turbine engines and forging equipment, material alone isn’t enough. The seal must have:

- Heat-expanding compensation grooves

- Self-centering lip profiles

- Multi-lip geometries to manage heat expansion

Seal geometry must allow movement without leakage, even when materials expand due to heat.

Hydraulic Piston Seals: Managing Pressure Differentials

Hydraulic piston seals are exposed to fluid pressure on one side and atmospheric conditions on the other. Their geometry must:

- Distribute load evenly across sealing surface

- Prevent extrusion into the clearance gap

- Maintain face stability under shock loads

Recommended profiles include:

- Symmetrical U-cups for bi-directional sealing

- Buffer seals with integrated anti-extrusion rings

- T-seals with dynamic groove interfaces

Incorrect groove width or shape leads to seal instability, especially during rapid stroke changes or thermal spikes.

Metal Clad Seals: Armor for Extreme Conditions

When polymer seals can’t cut it, metal clad seals are used. These hybrid seals combine metal casings with flexible sealing lips to:

- Resist deformation under intense pressure

- Prevent intrusion of abrasive particles

- Maintain sealing surface alignment at high RPMs

Geometry here plays a protective role:

- Rolled-edge cases for strength and vibration damping

- Swaged metal contours to ensure lip preload

- Dual-spring systems for face contact resilience

Metal clad seals are ideal for gearboxes, pumps, and pressurized systems with rotating shafts.

Geometry vs. Material: A Balanced Approach

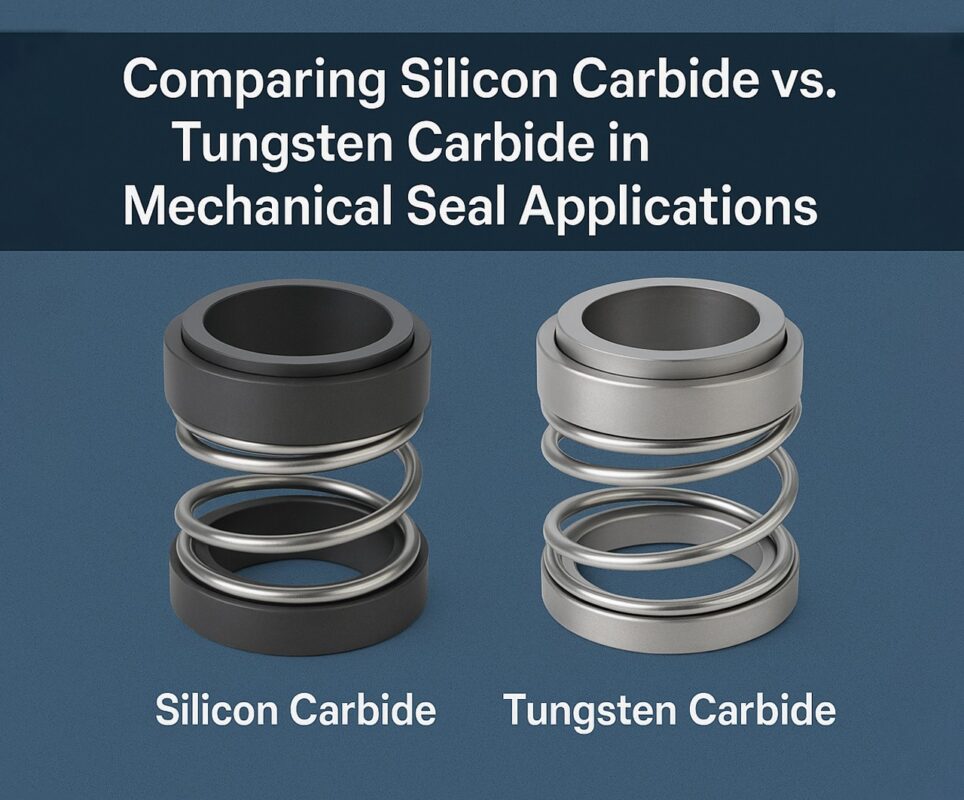

While choosing advanced materials like Viton, PTFE, or Kalrez is important, it’s the seal’s geometry that determines performance. Even the best high temperature oil seals will fail if the lip geometry doesn’t account for thermal expansion.

Successful systems balance:

- Groove width and depth

- Seal profile shape

- Material modulus under heat

- Pressure gradient across the lip

This is where computational fluid dynamics (CFD) and finite element analysis (FEA) can help engineers simulate stress distribution and fine-tune designs.

Design Tips for HPHT Seal Applications

- Use Rounded Edges: Reduces stress concentration

- Include Backups: Anti-extrusion rings improve resilience

- Test Lip Contact Angles: Affects hydrodynamic pressure zones

- Profile for Venting: Avoids pressure lock on reciprocating motion

- Account for Groove Fill: Material swell at temperature can impact tolerance

These principles are especially important in refining the design of hydraulic piston seals used in servo systems or deep-well oil tools.

Simulation and Prototyping: The New Standard

Modern sealing systems leverage software to predict behavior under HPHT conditions:

- 3D modeling of metal clad seals for rotating shafts

- FEA analysis of stress points in high temperature oil seals

- CFD flow modeling for fluid dynamics across lip profiles

Simulation reduces development costs, eliminates guesswork, and increases sealing reliability. Prototyping then validates the simulations before mass production.

Case Study: Oil & Gas Hydraulic Fracturing Unit

An OEM equipment manufacturer faced frequent failures in its hydraulic fracturing pumps due to:

- Poor groove compatibility

- Seal extrusion at high pressures

- Rapid thermal cycling cracking standard lip seals

Solution:

- Redesigned the hydraulic piston seals with a dual-lip, double-backup geometry

- Switched to PTFE-filled elastomers

- Integrated metal clad seals on rotating couplers

Results:

- Seal life increased by 400%

- Maintenance intervals extended from 2 weeks to 3 months

- Operating pressure capacity rose by 25%

Maintenance Best Practices for High-Performance Seals

- Inspect Seals Frequently: Look for cracking, lip wear, or extrusion

- Use the Right Lubricants: Some materials degrade under petroleum-based oils

- Avoid Over-Torquing Housings: Can deform seal geometry

- Standardize Installation Procedures: Torque specs and groove checks should be uniform

- Replace in Sets: Especially for paired hydraulic piston seals or double-ended rods

Training and consistency reduce installation-based failures and ensure seal longevity.

Looking Ahead: Future of Seal Geometry Innovation

- Smart Seals: Embedded sensors to track pressure, temperature, and wear in real-time

- Additive Manufacturing: 3D printed metal clad seals for micro-tolerances

- Self-Healing Elastomers: Materials that close micro-cracks under heat

- Bio-Compatible Seals: For pharma and food handling in HPHT settings

As system complexity increases, so will the demand for smarter, more geometry-driven sealing solutions.

Final Thoughts

Optimizing seal geometry for high-pressure, high-temperature systems is no longer a luxury—it’s a necessity. Engineers and operators who prioritize the design and function of high temperature oil seals, hydraulic piston seals, and metal clad seals will see longer lifespans, fewer breakdowns, and superior performance under the most demanding conditions.

In a world pushing limits, your seals need to hold the line. Design wisely. Test thoroughly. And always align geometry with application demands for best-in-class performance. Know more..