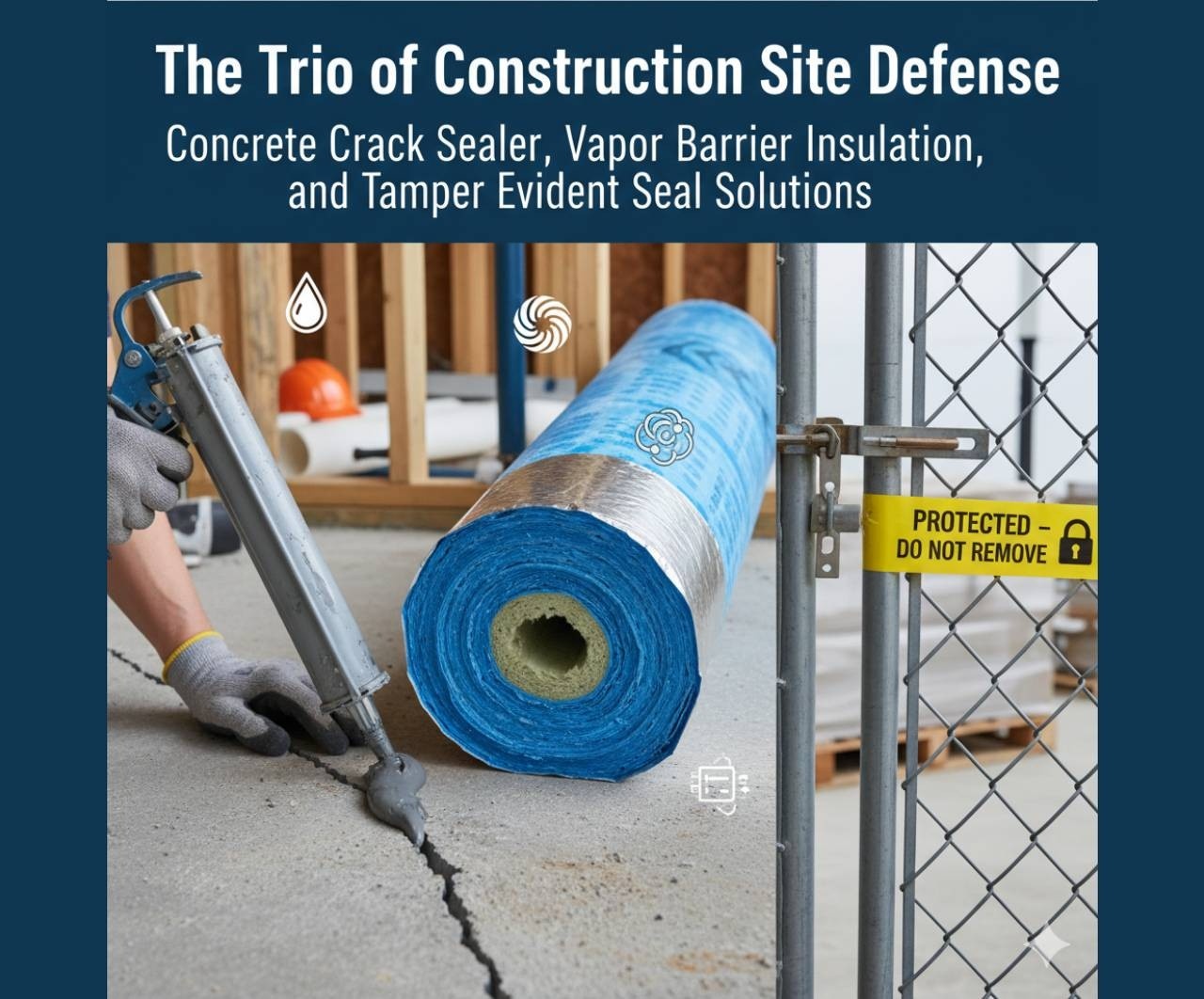

In the evolving landscape of construction site protection, three technologies are emerging as must-haves for forward-thinking contractors: concrete crack sealer, vapor barrier insulation, and the often-overlooked but increasingly critical tamper evident seal. Each of these tools targets a different layer of jobsite integrity—structural soundness, environmental control, and operational security—and together they form a holistic defense system that saves time, reduces risk, and ensures long-term quality. Know more..

Why These Three? Unified Protection from the Ground Up

Let’s break it down. A concrete crack sealer prevents structural failure by sealing early-stage fractures. Vapor barrier insulation preserves climate control and prevents moisture migration, which is crucial for indoor air quality and long-term durability. Meanwhile, the tamper evident seal secures materials, equipment, and access points—deterring theft and unauthorized use.

Each tool works independently, but when used in tandem, they create a powerful barrier—protecting against everything from environmental damage to jobsite sabotage.

Sealing the Foundation: The Power of Concrete Crack Sealer

When concrete starts to crack, time is of the essence. A premium-grade concrete crack sealer doesn’t just fill the gap—it bonds with the substrate, resists shrinkage, and adapts to seasonal expansion. Contractors using advanced concrete crack sealer products benefit from extended pavement life, improved water resistance, and reduced trip hazards.

We supply OEM-grade concrete crack sealer in both cold-applied and hot-pour formats, offering options for roadwork, foundation sealing, and even decorative concrete overlays. Every pail includes setting-time indicators and temperature guidance, ensuring consistency across job types.

Benefits of our latest concrete crack sealer line:

- UV resistance for long-term color and integrity

- Flexible under thermal cycling

- Compatible with traffic coatings and overlays

- Fast cure with minimal surface prep

Moisture Control Mastered: The Role of Vapor Barrier Insulation

While concrete crack sealer addresses visible damage, vapor barrier insulation works behind the scenes. It stops moisture vapor from penetrating walls, ceilings, and slab bases, which helps prevent mold growth and structural decay.

In commercial builds and high-performance homes, vapor barrier insulation is essential to meet energy codes and protect sensitive mechanical systems. Whether you’re retrofitting an aging structure or launching a new build, installing quality vapor barrier insulation can save thousands in potential water damage and energy loss.

Why our OEM partners love our vapor barrier insulation options:

- Multi-layer design for maximum resistance

- Reflective surfaces for radiant heat deflection

- Seam-compatible with concrete and timber

- UL-rated and LEED-compliant

Securing the Perimeter: The Importance of a Tamper Evident Seal

Construction sites face another kind of threat: theft, tampering, and unauthorized entry. That’s where the tamper evident seal comes in. Used on storage units, tool lockers, fuel drums, and even access control cabinets, a quality tamper evident seal offers immediate visual cues if compromised.

Unlike basic padlocks or zip ties, a tamper evident seal can’t be removed or resealed without clear evidence. Our ISO-certified tamper evident seal products feature serial numbers, barcode tracking, and breakaway mechanisms—ideal for high-value or restricted materials.

Applications of a tamper evident seal on-site:

- Equipment trailers and jobsite boxes

- Chemical storage drums

- Temporary power supply cabinets

- Controlled tool issue systems

How the Trio Works Together: Site-Wide Reliability

Let’s visualize the layered defense system. First, your crew lays down vapor barrier insulation to protect interior spaces. Then, they use concrete crack sealer to address any emerging surface damage—locking out water, chemicals, and structural stress. Finally, materials and systems are protected with a tamper evident seal to prevent theft and ensure accountability.

By addressing the physical, environmental, and operational layers, this trio reduces downtime, material loss, and regulatory headaches.

Real-World Results from Contractors

We’ve worked with municipal construction crews, residential developers, and utility contractors who’ve all implemented this trio successfully. One paving contractor in Colorado used our concrete crack sealer and saw a 35% reduction in rework over a 12-month span. A mechanical contractor in the Midwest adopted our vapor barrier insulation across multiple HVAC retrofits and passed all energy audits on first inspection. And a logistics firm deployed our tamper evident seal products on their tool trailers—leading to a 90% drop in reported site theft.

When these tools work together, projects run smoother. Labor is better utilized. Materials stay secure.

Sustainability Gains and Compliance Benefits

Using our eco-certified concrete crack sealer and LEED-approved vapor barrier insulation helps contractors meet growing green building standards. Likewise, our recyclable tamper evident seal systems help reduce single-use plastic waste, while improving logistics traceability.

We also provide documentation for each component to simplify inspections and bid submissions—ideal for government or publicly funded jobs requiring traceable materials.

OEM and Wholesale Advantages

As an OEM and wholesale supplier, we offer custom labeling, volume pricing, and integration services for project-specific bundles that include:

- Multiple grades of concrete crack sealer

- Roll and panel-based vapor barrier insulation

- Serialized tamper evident seal kits in bulk

We work directly with site planners to forecast material usage, ensure compatibility with other jobsite systems, and ship pre-packed configurations for easy on-site deployment.

Storage, Handling, and Usage Tips

Concrete Crack Sealer

- Store indoors at moderate temperatures

- Stir thoroughly before use

- Use backer rod for deep cracks

Vapor Barrier Insulation

- Always overlap seams by at least 6 inches

- Seal with vapor-rated tape

- Avoid puncturing during drywall or cladding

Tamper Evident Seal

- Record serial numbers before use

- Apply on dry, clean contact points

- Discard once broken—never reuse

The Future of Integrated Site Protection

Looking ahead, the demand for jobsite integration will only grow. Crews want seamless workflows. Supervisors want fewer call-backs. Procurement wants cost-efficient solutions. This trio—concrete crack sealer, vapor barrier insulation, and tamper evident seal systems—meets all of these needs while aligning with code requirements, sustainability benchmarks, and real-world performance goals.

We’re already working on smart versions of the tamper evident seal, equipped with NFC tracking and auto-logging, and collaborating with insulation manufacturers to embed sensors into vapor barrier insulation for moisture alerts.

Final Thoughts: One Trio, Countless Benefits

Whether you’re protecting a parking garage, a hospital, or a multi-family complex, it pays to think in layers. The combined force of concrete crack sealer, vapor barrier insulation, and a reliable tamper evident seal system ensures that your project is secure, efficient, and ready to meet the future.

Looking to bundle these solutions for your next job site or distribution line? Contact our OEM team to explore our complete lineup of concrete crack sealer, high-performance vapor barrier insulation, and serialized tamper evident seal options—designed for contractors who demand results.